@iantelescope this is very interesting but I am at a loss as to what you are trying to prove so please explain 🙂

Posted by: @iantelescopeSwitching and Water Flow rates can be Safely controlled by the PWM inputs rather than Power Relays!

I think you misunderstand regarding the suggestion of using a relay. The relay is to switch the power to the pump on and off not control its speed. You are trying to get a static speed in your secondary pump to achieve the required flow rate around your radiator circuit. The pump needs to be switched on and off by your Samsung controller in order to separate the dependency of the pump from your Honeywell thermostat.

The Samsung controller output is only capable of supplying up to 100W so you need to use a relay to switch the power on and off for a pump that consumes power greater than 100W otherwise it will damage your control board. The pump relay, via this Samsung output, will only be switched on and off in sync with your heat pump compressor etc, which in turn powers your pump on and off, it is not used to produce a pulse train to control the pump speed, merely the electrical power to the rotor.

I am not sure how this secondary PWM pump was controlled before you used your Arduino but I hazard a guess it was running a constant speed when first installed?

If a constant speed configuration is not possible with your PWM pump then you may have to consider a fixed speed pump replacement such as a Wilo pump on which you can manually set the required head pressure and get the desired flow rate.

Regards

5 Bedroom House in Cambridgeshire, double glazing, 300mm loft insulation and cavity wall insulation

Design temperature 21C @ OAT -2C = 10.2Kw heat loss, deltaT = 8 degrees

Bivalent system containing:

12Kw Samsung High Temperature Quiet (Gen 6) heat pump

26Kw Grant Blue Flame Oil Boiler

4.1Kw Solar Panel Array

34Kwh GivEnergy Stackable Battery System

It would have probably been more useful to show the inlet and outlet temperatures on the primary side of the PHE along with the inlet and outlet temperatures on the secondary side. All on the same chart if possible.

Flow rate and DT are inter-related, though it may be useful if I try to explain using voltage (DT), current (flow rate) and variable resistance to represent heat emitters.

Consider a system that has 10 radiators (10 x 10 Ohm resistors) all connected in parallel. If the supply voltage is 10 volts then 1 amp will flow through each resistor, producing a total supply current of 10 amps. The total amount of power being dissipated by the resistors will be V x I, giving 10 x 10 = 100 watts.

If each resistor is now reduced to 5 Ohms, then at a supply voltage of 10 volts, the total supply current would increase to 20 amps, giving a total power dissipation of 200 watts. To keep the power dissipation at 100 watts it would be necessary to reduce the supply voltage from 10 volts to 5 volts.

If the above is now consider in a slightly different way, in that the current (flow rate) is fixed at say 10 amps, but that the resistance is varied to vary the amount of power dissipated, with the volt drop across the resistors indicating the produced DT.

For a power dissipation of 100 watts the produced volt drop would be 10 volts.

For a power dissipation of 50 watts the produced volt drop would be 5 volts.

For a power dissipation of 20 watts the produced volt drop would be 2 volts.

It is probable that your charts are showing that a similar quantity of thermal energy (power) is being dissipated, but by changing the flow rate (current), the DT (volt drop) is being changed.

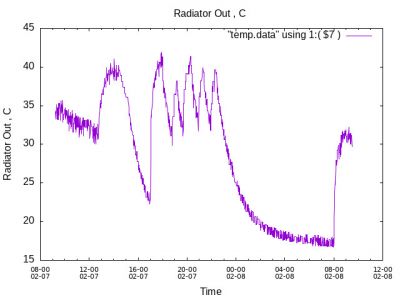

Changing the flow rate in either the primary or secondary side of the PHE will change the relevant DT.

For Efficiency , Hot Water Heating DOES NOT NEED the Radiator Motor Water Pump to be AUTOMATICALLY USED.

Many thanks @derek-m

Sensors .....more & More & more!

I am building a permanent box to increase my DS18B20 Temperature Array to 12 X DS18B20 and another Arduino .

I will measure and control the Secondary , Radiator Delta_t ...........in due course.

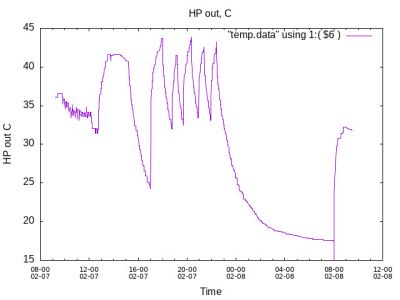

In limiting the Flow rate , I have greatly increased the Primary Delta_t.

Note that the PWM input to the Grundfoss Motors was used to reduce and control the Flow rates NOT the RELAYS.

Parallel Grundfoss Motor Operation:

For efficiency when Heating Hot Water the Radiator Motor Water Motor SHOULD NOT BE AUTOMATICALLY USED.

Parallel Grundfoss Motor Operation WOULD BRING BOTH PUMPS into operation when ONLY ONE MAY BE REQUIRED!.

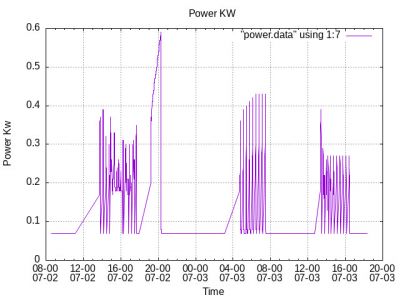

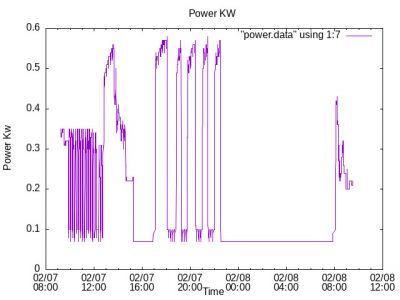

Note the different Amplitudes, reflecting the Single or DUAL Motor Operation.

The Thermostat SIGNAL does NOT ALWAYS start the Compressor OR the Primary Grundfoss Water PUMP.

Thermostat Cycling and Weather Compensation Cycling:

During a Cold February my Heat Pump Cycle Time is controlled by BOTH Weather Compensation AND my Thermostat.

The following graphs show the Power , Heat PUMP Output Water Flow Temperature and Radiator Output Water Flow Temperature on 7th February 2023.

The 10 Shorter 10 minute "Short Cycling " is here vividly contrasted with the 1 Hour Cycling Time set by the Weather Compensation Thermostat.

My Conclusion is that Weather Compensation is perfectly capable of controlling BOTH THE Primary AND SECONDARY,RADIATOR Grundfoss Motors!.

I further conclude that , in the absence of my Thermostat 20 minute "Cycle Time " my Heat Pump would revert to Weather Compensation.

The Buffer tank Controversy

Given that the Buffer tank appears to provide a Winter "Cycle Time " of one hour, I should Replace the Thermostat with a Simple ON-OFF Thermostat !

Water FLOW RATE Control

Given the proven operation of the PWM in increasing the Heat Exchanger Delta_t WHY are RELAYS BEING Advocated ?

Case 1 , PWM OR Case 2 , RELAY ??

Why SHOULD I USE CASE 1 , the Pulse Width Modulation , PWM Grundfoss Motor Control to control the Primary Water Flow rate as illustrated in the Installation manual?

Why SHOULD I USE CASE 2 , Relay Control , to control the Primary Water Flow rate , as illustrated in the Installation manual?

PWM proving to be MUCH Simpler & Safer !!

@technogeek and @derek_m

Why , on earth are SAMSUNG, Still , in the 21st century using RELAYS ??

My Grundfoss Motors can be Switched OFF AND ON using a PWM Signal :

My Grundfoss motor can return its status:

When used , the PWM Grundfoss motors , case 1 in the SAMSUNG Installation Manual the 240ac are permanently ON ( see installation manual)

Hysteresis:

The PWM signal when operating at 4 khz or 256 us has a Hysteresis from 91% , or 233 us to 95% , or 243 us .

Overheating safety limit :

The PWM signal when operating with a signal < 10% , or 25 us , is fixed at Maximum Speed ensuring maximum speed during Signal failure.

When Signal noise is between 0 and 10% the Motor is driven at maximum speed cooling the water , and motor.

Feedback:

The PWM Motor returns the Alarm and motor Status with current consumption. This is NOT currently used by SAMSUNG.

Speed Control Linearity :

The PWM is linear between the OFF Speed , 256 us Pulse width and the ON Pulse Width of <10 us.

Why , on earth are SAMSUNG, in the 21st century STILL using RELAYS ??

A Simple ON-OFF No-nonsense Radio Controlled Thermostat ?

Where Can I Get a Simple ON-OFF Radio controlled Thermostat ?

Most of the on line Thermostats, on offer, do not have sufficient Technical Information, being aimed at "simplicity of operation " , "Looks" , and "simplicity of installation" !

Samsung's Embarrassment Required:

Following a E-mail exchange with a anonymous Samsung Engineer, he was of the frank opinion that Samsung would Do Nothing about my "Installation " unless embarrassed !.

Without a dose of embarrassment Samsung would , probably, demand payment for their services!

He further commented that 80% of the "Faulty installations " were caused by incompetent "installers",

, with the remaining "probably caused" , as in my case , by Samsung.

I have a Samsung Heat Pump designed by nobody , built by nobody, taking four months to install!

The NIC / MCS "regret that they can DO NOTHING , given that my "installer" has been "STRUCK OFF SEVERAL TIMES in the last TWO Years".

Struck off, and repeatedly re-instated by the MCS themselves!

@derek--m & @technogeek

Have you a Heat Pump with a Heat Exchanger , a Buffer, using BOTH AC Pump AND PWM ?

Controlling Water Samsung Water Pumps:

Water Flow in Samsung Heat Pumps can be controlled by either

1) The INV Option, Case 1 in the Installation manual:

Control: The Water flow is here controlled by a Pulse Width Modulated , PWM signal from a socket on the MIM--E03CN Control PCB.

Range: The Water flow rate is continuously , and linearly , variable between OFF and ON.

Power: The AC power is continuously ON being supplied from pin B6 , Continuous Live , and B7 Neutral.

PWM Range:Driven at 4 Khz , ON has a Pulse width of between 0 an d 25 us, while OFF is a Pulse Width of between ~240 and 256 us.

Cost : PWM Motors are more costly than AC controlled motors..

Safety: PWM Systems, being Semiconductor Technology, Should be much more reliable and safe compared to mechanical Relays used by the AC Pump option:

PWM Motors have Feedback , currently NOT USED by Samsung.

Water Power : To increase water flow rates beyond the current motor power a replacement PWM motor , with increased power would be required.

Zero Check: The Samsung control board checks for excessive power when commanded to switch OFF , issuing a E912 Error if water flow is greater zero.

Run check : The Samsung control board checks for Power less than ~15 lpm when commanded to switch ON , issuing a E911 Error if water flow is less than 15 lpm.

2) The AC Pump option, case 2 in the Installation manual:

Control: The Water flow is here controlled by an Electromechanical Relay on the Control Board.

Range : The Water flow rate is either ON or OFF. No Flow rate variation is possible.

Power: The AC power is continuously Switched being supplied from pin B8 , Live , and B7 Neutral.

Cost : AC Motors are cheaper, and more readily available compared tp PWM controlled motors.

Safety: AC Relays Systems, being Electro-mechanical , are much Less reliable with reduced and safety compared to PWM Solid state controls.

Water Power : To increase water flow rates beyond the current motor power another motor can be operated in parallel with the current motor. Another Relay would, however be required.

Zero Check: The Samsung control board checks for excessive flow rate when commanded to switch OFF , issuing a E912 Error if water flow Rate is greater than zero.

Run check : The Samsung control board checks for Power less than ~15 lpm when commanded to switch ON , issuing a E911 Error if water flow is less than 15 lpm.

Who else has a system like mine, A Heat Pump with a Heat Exchanger , a Buffer with BOTH AC Pump AND PWM used?

Posted by: @iantelescopeHave you a Heat Pump with a Heat Exchanger , a Buffer, using BOTH AC Pump AND PWM ?

I have a 12Kw Samsung connected to standard radiators via a low loss header. The primary water circuit to the low loss header is pumped using a PWM Grundfoss pump and the secondary circuit pumped to the radiators is a fixed speed Wilo pump set with an approx 10 metre head as it is supplying 13 rads in a 5 bedroom house.

Samsung is capable of controlling 1 PWM pump only and 1 fixed speed pump simultaneously.

Regards

5 Bedroom House in Cambridgeshire, double glazing, 300mm loft insulation and cavity wall insulation

Design temperature 21C @ OAT -2C = 10.2Kw heat loss, deltaT = 8 degrees

Bivalent system containing:

12Kw Samsung High Temperature Quiet (Gen 6) heat pump

26Kw Grant Blue Flame Oil Boiler

4.1Kw Solar Panel Array

34Kwh GivEnergy Stackable Battery System

Again Many Many thanks............................@technogeek

My Samsung , fitted with a PWM Grundfos motor is fed from a Faulty PWM Unloaded Output signal.

This is the PWM signal when Not connected to the Grundfos Motor:

Clearly the Signal exists But never drops to Zero!

When connected to the Grundfos motor I get :

Clearly , my PWM Source is Faulty never dropping to Zero Volts.

The Grundfos PWM Input to the Primary PWM motor works flawlessly, when sourced from an Arduino::

As does my Radiator , Secondary when fed from an Arduino :

I speculate that Someone has tried to connect the PWM Source on the Samsung PCB to something other than a motor !.

I will have to replace the Samsung PCB to get the PWM System working .

The Secondary , Radiator Pump will have to use either the Thermostat connected to the 240 ac

OR a Arduino Generated Control again ONLY switched ON / OFF by the Thermostat .

many thanks

Can you measure the DC PWM Reference pin voltage on your Samsung PCB?

Hi @technogeek:

Given that my Samsung PCB produces a passable output PWM signal , is it possible that the "PWM Reference" pin on my Samsung PCB is wrongly connected?

Could you measure the DC PWM Reference pin voltage on your Samsung PCB?

My PWM Signal is being killed by my Grundfos!.

Hi Again, thanks for your patience!

What are your Samsung Inverter Pump settings Field bits, 4051 :

1) Used or Not used

2) 70 % Modulation

3) 100 % Modulation

4) Target Delta T

5 ) Control factor

My "Home made" Arduino continues to generate a similar Inverter motor performance.

My Samsung inverter Motor control continues to fail when driven by my Samsung PWM PCB output .

My PWM Signal is being killed by the Grundfos motor PWM itself.

any ideas?

P.S. It is NOT Cable polarity !

@iantelescope I could be completely wrong when I say this but the first 2 photographs look to me as the classic floating neutral. That maybe why it never gets to zero in the first photo and gets pulled up to the rail when connected to the motor in the second. Is your neutral correctly wired to the correct pcb terminal and making a good connection?

My system is set to 100% modulation for PWM and a delta T of 5 degrees C. Leave the control factor at default

Regards

5 Bedroom House in Cambridgeshire, double glazing, 300mm loft insulation and cavity wall insulation

Design temperature 21C @ OAT -2C = 10.2Kw heat loss, deltaT = 8 degrees

Bivalent system containing:

12Kw Samsung High Temperature Quiet (Gen 6) heat pump

26Kw Grant Blue Flame Oil Boiler

4.1Kw Solar Panel Array

34Kwh GivEnergy Stackable Battery System

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 357 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: A Smarter Smart Controller from Homely?

@papahuhu I have apps on update and check (sad that I a...

By Toodles , 20 minutes ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Thank you. Absolutely, it's nice and cozy. Would ...

By GoodbyeGas , 29 minutes ago

-

RE: Electricity price predictions

@batpred You only need to look at a few figures to see ...

By dr_dongle , 1 hour ago

-

RE: Setback savings - fact or fiction?

It's close enough to steady (+/- 35W) to get reasonably...

By RobS , 2 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Yes, but I need to reopen the battery box.. I just noti...

By Batpred , 3 hours ago

-

Hi Mars,We have discussed my Octopus install on YouTube...

By Rob , 3 hours ago

-

RE: Our Experience installing a heat pump into a Grade 2 Listed stone house

@travellingwave Ah yes, that would explain it. &n...

By RobS , 4 hours ago

-

RE: What determines the SOC of a battery?

While the sun was shining yesterday my batteries got to...

By JohnnyB , 5 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Ah, that is much clearer, my manual doesn't have the st...

By cathodeRay , 6 hours ago

-

RE: The Hidden Secret to a Successful Heat Pump: Pipe Size Matters

If your heat loss is only 4kW and the pipes leaving the...

By JamesPa , 7 hours ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

My 2 bed mid-terrace definitely dropped consistently af...

By RadWhisperer , 10 hours ago

-

RE: Say hello and introduce yourself

You can send private messages via the Messages (envelop...

By cathodeRay , 23 hours ago

-

RE: Peak Energy Products V therm 16kW unit heat pump not reaching flow temperature

With complete radio silence from Peak and no sign of th...

By DaveC , 24 hours ago

-

I understand now what you were referring to. This look...

By trebor12345 , 1 day ago

-

No you arent, because you dont need any, and furthermor...

By JamesPa , 1 day ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

As I mentioned earlier most radiators have a power outp...

By JamesPa , 1 day ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 2 days ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 3 days ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 3 days ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 3 days ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 3 days ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 3 days ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 3 days ago