postid="31563"]

Disadvantages:

The Thermostat minimum cycle time of twenty minutes, with a PWM Run time of between 3 and 8 minutes, the Grundfoss Motors and the PCB Relays are being damaged.

As I have mentioned in a previous post if you are in mode 3 for field value #4091 (if I remember correctly). This means the compressor and water pump are switched on and off by the honeywell thermostat or just the compressor by the water law. To increase the cycle time of the thermostat you need to lower your flow temperature enough to maintain your room temperature but maximise your thermostat "on" time per cycle.

Trying to acheive this in mid summer is near impossible and the honeywell will have short cycle times to try and acheieve such low flow temperatures.

Regards

5 Bedroom House in Cambridgeshire, double glazing, 300mm loft insulation and cavity wall insulation

Design temperature 21C @ OAT -2C = 10.2Kw heat loss, deltaT = 8 degrees

Bivalent system containing:

12Kw Samsung High Temperature Quiet (Gen 6) heat pump

26Kw Grant Blue Flame Oil Boiler

4.1Kw Solar Panel Array

34Kwh GivEnergy Stackable Battery System

Is the Honeywell thermostat merely starting and stopping the secondary water pump or does it also start and stop the compressor and primary water pump?

@derek-m by applying 240v to the thermostat input terminal (which the honeywell does) then depending on which mode is selected in the Samsung controller (#4091 I think) then the behaviour of the heatpump is as follows, that is the compressor and PWM primary water pump:

Option 1: The compressor and water pump are switched on and off by the thermostat only.

Option 2: The compressor and water pump are switched on and off by the thermostat or the compressor alone is switched on and off by the water law (weather comp) value. The water pump has a 1 minute overrun.

Option 3: The compressor and water pump are switched on and off by the thermostat or the compressor alone is switched on and off by the water law ( weather comp) value. Water pump has no overrun

Option 4: The compressor and water pump run for 3 minutes then switch off for 7 minutes, back on for 3 minutes, off for 7 minutes. This is continuous while the thermostat demands heat, ie applys 240v to the thermostat input of the Samsung controller.

Samsung controllers only have one PWM pump output. A second pump can be connected via a relay to a secondary pump terminal but it is a simple on off signal, so constant speed pumps only. The switching of this pump is in sync with the primary pump.

Hope that helps clarify things 😀

Regards

5 Bedroom House in Cambridgeshire, double glazing, 300mm loft insulation and cavity wall insulation

Design temperature 21C @ OAT -2C = 10.2Kw heat loss, deltaT = 8 degrees

Bivalent system containing:

12Kw Samsung High Temperature Quiet (Gen 6) heat pump

26Kw Grant Blue Flame Oil Boiler

4.1Kw Solar Panel Array

34Kwh GivEnergy Stackable Battery System

@derek-m by applying 240v to the thermostat input terminal (which the honeywell does) then depending on which mode is selected in the Samsung controller (#4091 I think) then the behaviour of the heatpump is as follows...........................................

Many thanks @Technogeek for your interpretation of the 2091 settings on the Samsung Controller.

Speaking from experience , I would agree with your interpretation. This is, probably, how it should work.!

I do wish, however, that Samsung produce a proper explanation of the 2091 controls on Samsung heat pumps.

My System..... reality :

Hydraulic Isolation:

My Samsung is fitted with a Heat Exchanger isolating the Heat Pump Water pipe output from the Radiator pipe circuit.

If ,say , the user were to stop water flowing in the Radiators the primary Water Flow would be unaffected. A "safety measure" protecting the Heat Pump ?.

The division of the Water flow into two circuits also allows the use of Glycol in the Primary , outdoor water circuit, with a safer , and higher Specific Heat Fluid in the Radiator circuit.

Two Water Circuits separated by a Heat Exchanger:

Primary , Heat Pump Water circuit :

The Primary Water circuit runs from the Heat Pump , situated in my garden, to the Input ports of the Heat Exchanger.

The Water Temperature in the primary circuit is controlled by the Weather compensation Thermostat, with the Weather compensation sensor attached to the rear of the heat Pump.

The Primary Water circuit has a Grundfoss PWM Motor controlled by the Samsung Controller PCB. The PWM input was not , initially, used.

Secondary, Radiator Water Circuit:

The Secondary Radiator Water circuit flows from the output ports of the Heat Exchanger around my house radiator circuit.

The Secondary Water Circuit has a second Grundfoss PWM Motor directly controlled by the Honeywell Thermostat located in my living room.

The Honeywell Thermostat is directly connected, using the Thermostat 240 AC output to the Second Grundfoss Motor .

The Honeywell Thermostat is also connected to pin B22 of the Samsung Control Board , which, I believe, is the " normal" Heat Pump "RUN " Demand.

The Honeywell Thermostat therefore directly controls the Secondary Motor AND ,Simultaneously, Demands that the Compressor runs!

Although fitted with an expensive PWM Grundfoss motor the PWM was NOT , initially , used.

The Honeywell Thermostat:

Four weeks ago I discovered that the "Short cycling" was caused by the Honeywell cycle settings.

I suspect that the Honeywell Thermostat was designed to limit cycling by specifying the Cycle Time while controlling the RUN TIME. Essentially a form of Pulse Width Modulation.

Should I replace the Honeywell Thermostat?

Given that the Honeywell Thermostat was probably designed to limit Cycling by fixing a set Cycle Time, while varying the RUN Time , should I replace it?

Pipe Water Flow rates:

To improve the Delta_t across the Primary ports of the Heat Exchanger I have reduced the Water Flow rates to just above the minimum set by the E911 water flow errors.

I cannot therefore reduce the primary water flow to increase the Run time of the Honeywell Thermostat.

So called 'Smart' thermostats such as the Honeywell were developed for use with gas or oil boilers, to help control the IAT more accurately.

A basic thermostat may be set to switch on the heating when the IAT falls to 20C, and switch off the heating when the IAT has reached 21C. Because of the inherent time delays, the actual IAT will fall below 20C before it starts to increase, and will overshoot 21C after the heating is switched off. During the heating cycle the boiler could be on continuously for an hour or more.

To help control the IAT more accurately smart thermostats were developed to run the heating system for shorter periods, but more frequently, thereby limiting any undershoot or overshoot and provide a more constant IAT. This philosophy works fine with gas and oil boilers, but not so with heat pumps.

A basic on/off type thermostat should therefore be used with a heat pump.

Posted by: @iantelescopeMany thanks @Technogeek for your interpretation of the 2091 settings on the Samsung Controller.

Speaking from experience , I would agree with your interpretation. This is, probably, how it should work.!

I do wish, however, that Samsung produce a proper explanation of the 2091 controls on Samsung heat pumps.

This #2091 option information is straight out of the Samsung user manual (which your installer should have left you a copy). I can copy the pages onto this thread when I get back to the UK if this is going to help?

Regards

5 Bedroom House in Cambridgeshire, double glazing, 300mm loft insulation and cavity wall insulation

Design temperature 21C @ OAT -2C = 10.2Kw heat loss, deltaT = 8 degrees

Bivalent system containing:

12Kw Samsung High Temperature Quiet (Gen 6) heat pump

26Kw Grant Blue Flame Oil Boiler

4.1Kw Solar Panel Array

34Kwh GivEnergy Stackable Battery System

ref: Control manual:

Hi , Many thanks for your swift response!

The 2091 options:

The Control manual ( I have 2 old versions and one new version ) explains the "What" of 2091 options, not the "Why or When to use " these options.

When, for example , should the 2091 option 4 , with it's 3 minute / 7 minute option be used?

When asked what is the practical difference between the 2091 options , a Visiting French-Samsung engineer replied ........in his experience , not much!".

PWM or Switched relay Water Motor Control:

The French SAMSUNG Engineer was equally dismissive of the Samsung Pulse Width Modulation , PWM, motor control option, shown in case 1 of the control manual, saying that "he only used case 2 ", the relay motor control system.

He advised, when shown my "excessive Short Cycling ", that I consider fitting the extra Relay shown in case 2 to protect the PCB Relays on the Samsung, which were, in his experience , prone to failure!

His final comment "That Germans Really understood the PWM System , He did Not!" was revealing!

Slowing water rate to increase the Honeywell Run time:

The Water flow rate has already been reduced to just above the E911 flow rate limit.

The Water rate was reduced on both Water circuits using the Grundfoss PWM controls to increase the poor Delta_t across both Heat Exchanger ports.

Delat_t increases:

Delta_t has been increased on both ports resulting in a Delta_t of between 4 and 5 C by reducing the Water flow rates on both water circuits using the PWM Motor ports.

The increased Dela_t should reduce the Energy reflected from the Radiator circuit...........

the parallels between water pipes and Transmission lines are fascinating....!

Posted by: @iantelescopeWhen, for example , should the 2091 option 4 , with it's 3 minute / 7 minute option be used?

I think Samsung intended this option to save energy however this should never be used especially when trying to achieve a continously running system like you are. Option 3 will run the water pumps for as long as the thermostat calls for heat and the compressor is controlled by both the thermostat and water law. The longer the thermostat calls for heat the longer the heatpump will run. This can be achieved by lowering your flow temperature enough to maximise your thermostat cycle time but maintain your set room temperature.

However as the Winter season progresses you will have to make slight adjustments to the water law (weather curve) to maintain max cycle time and constant desired room temperature. You should by the end of the Winter have a reasonable weather curve set up.

This is all in addition to the recommendations @derek-m has made regarding setting your flow rates correctly and isolating the buffer tank to achieve max heat transfer across your heat exchanger 😀

Regards

5 Bedroom House in Cambridgeshire, double glazing, 300mm loft insulation and cavity wall insulation

Design temperature 21C @ OAT -2C = 10.2Kw heat loss, deltaT = 8 degrees

Bivalent system containing:

12Kw Samsung High Temperature Quiet (Gen 6) heat pump

26Kw Grant Blue Flame Oil Boiler

4.1Kw Solar Panel Array

34Kwh GivEnergy Stackable Battery System

Looking at the manual for the controller I would interpret the setting of 2091 and 2092 in the following manner.

2091 & 2092 set to value 1.

The compressor (and probably water pump) will be turned on and off only by the room thermostat and will ignore the WL settings.

2091 & 2092 set to value 2.

The compressor will be turned on and off by the room thermostat or by the WL settings when the LWT reaches the upper limit. The primary water pump will also be switched on at the same time as the compressor, but the switch off will be delayed by 1 minute. I am not certain if the 1 minute delay is also present if the switch off is caused by the room thermostat.

2091 & 2092 set to value 3.

The compressor will be turned on and off by the room thermostat or by the WL settings when the LWT reaches the upper limit. The primary water pump will continue to run if the switch off is due to the WL setting. I am not certain if the water pump will continue to run if the switch off is caused by the room thermostat.

2091 & 2092 set to value 4.

The compressor will be turned on and off by the room thermostat or by the WL settings when the LWT reaches the upper limit. The primary water pump will be kept running for 3 minutes then off for 7 minutes if the switch off is due to the WL setting. I am not certain if the water pump will continue to run if the switch off is caused by the room thermostat.

If my assumptions are correct I would expect your system to operate in the following manner, but will be dependent upon how the different items have been wired.

2091 & 2092 set to value 1.

I suspect that if the switch off is initiated by the room thermostat then both the compressor and the primary water pump (possibly after a delay) will stop and will not restart until initiated by the room thermostat switching on. It is likely that the secondary water pump will also be stopped. This may also be the case when 2091 and 2092 are set to values of 2, 3 or 4. This should be easy enough to check by turning the room thermostat high and then low.

2091 & 2092 set to value 2.

If the room thermostat is calling for heat, but the LWT rises to the upper limit, the compressor will be stopped but the primary water pump will continue to run for a further 1 minute. This I believe is to extract the remaining thermal energy from the PHE within the heat pump. I would also expect the secondary water pump to also run at the same time as the primary.

2091 & 2092 set to value 3.

If the room thermostat is calling for heat, but the LWT rises to the upper limit, the compressor will be stopped but the primary water pump will continue to run continuously. This should help keep the LWT uniform and so delay the restarting of the compressor once the LWT has fallen to the lower limit. It should also be beneficial if the secondary water pump was also kept running, to allow the transfer of thermal energy from the secondary circuit to the primary and thereby extending the cooling down period.

2091 & 2092 set to value 4.

If the room thermostat is calling for heat, but the LWT rises to the upper limit, the compressor will be stopped but the primary water pump will continue to run for 3 minutes, then stop for 7 minutes and repeat. This mode should also extend the cooling down time but use slightly less electrical energy since the water pump is not operating continuously. The secondary water pump should mimic the primary.

I would not expect the compressor to be running for 3 minutes and stopping for 7 minutes.

I would suggest that you try the different modes and closely monitor the operation of the different components.

Hi,

Many thanks to both of you. You have restored some belief in myself , Heat Pumps and yourselves.

Mid-summer madness:

As you said earlier , measuring anything during mid-summer is nigh impossible.......

Every midsummer measurement is either bathed in noise , flat zero or results in a divide by Zero in spreadsheets!.

Measurements after Honeywell :

With the discovery of the Thermostat as the cause of most of my "Short cycling" , I will restart sequentially changing the 2091 parameters.

Given measurement Weather variability I will change each parameter once a week .

Standard Temperature Sensor change:

I have , today, changed the "Standard Temperature " Sensor setting from "Water inlet" to "INDOOR".

If this setting provides any advantage I will replace the sensor at the rear of the LCD Screen with the external Sensor kit , MRW-TA , fitted into my living room.

Given that the secondary motor needs a Switched Thermostat confusion may result !

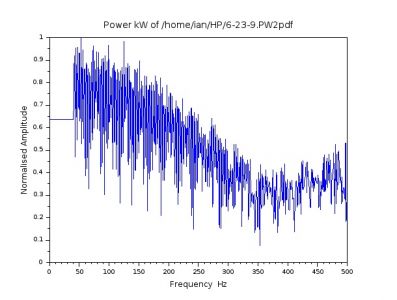

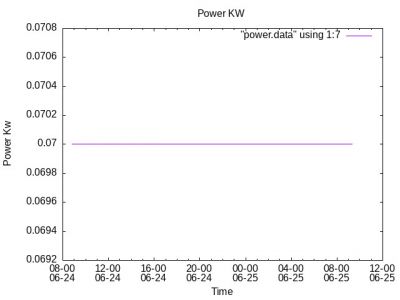

It is unclear what your charts are measuring or designed to show.

I would suggest plotting temperatures throughout your system against time, which should hopefully allow an assessment of what is occurring.

Do the two water pumps stop and start at the same time? When does the compressor run in relation to the water pumps? When does the compressor run in relation to the room thermostat?

The more information that you can provide, the better assessment that it should be possible to obtain.

I would caution against making changes to the mode of operation until a full assessment has been completed.

Posted by: @derek-m#2091 and #2092 set to value 2

The compressor will be turned on and off by the room thermostat or by the WL settings when the LWT reaches the upper limit. The primary water pump will also be switched on at the same time as the compressor, but the switch off will be delayed by 1 minute. I am not certain if the 1 minute delay is also present if the switch off is caused by the room thermostat.

You are almost correct. Option 2, the water pump is switched on and off by the room thermostat but continues running for 1 minute after the thermostat switch off. The compressor switches on and off either by the room thermostat or the water law limit. If the water law temperature is reached while the thermostat is still calling for heat the compressor slows or stops but the water pumps continue until the LWT drops sufficiently to start the compressor again, ie the compressor cycles around the required LWT target calculated by weather compensation until the room thermostat stops calling for heat.

Posted by: @derek-m2091 & 2092 set to value 3.

The compressor will be turned on and off by the room thermostat or by the WL settings when the LWT reaches the upper limit. The primary water pump will continue to run if the switch off is due to the WL setting. I am not certain if the water pump will continue to run if the switch off is caused by the room thermostat.

Same behaviour as option 2 BUT no 1 minute overrun of the water pumps after the room thermostat switch off. The water pumps switch off the same time as the room thermostat

Posted by: @derek-m2091 & 2092 set to value 4.

If the room thermostat is calling for heat, but the LWT rises to the upper limit, the compressor will be stopped but the primary water pump will continue to run for 3 minutes, then stop for 7 minutes and repeat. This mode should also extend the cooling down time but use slightly less electrical energy since the water pump is not operating continuously. The secondary water pump should mimic the primary.

On my system (and I suspect on ian's) the compressor & water pumps run for 3 minutes then stop and the controller goes into standby. 7 minutes later the compressor and water pump switch on again for 3 minutes then off for 7 minutes. This behaviour continues while the room thermostat calls for heat. The problem is 3 minutes is not long enough to generate the required flow temp which cools too much during the 7 minute off period loosing what little gains the HP made

Regards

5 Bedroom House in Cambridgeshire, double glazing, 300mm loft insulation and cavity wall insulation

Design temperature 21C @ OAT -2C = 10.2Kw heat loss, deltaT = 8 degrees

Bivalent system containing:

12Kw Samsung High Temperature Quiet (Gen 6) heat pump

26Kw Grant Blue Flame Oil Boiler

4.1Kw Solar Panel Array

34Kwh GivEnergy Stackable Battery System

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 676 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

My 2 bed mid-terrace definitely dropped consistently af...

By RadWhisperer , 3 hours ago

-

RE: Electricity price predictions

I agree incentives are needed. We are an unusual home b...

By Batpred , 9 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos interesting. I might look into that. My other op...

By benson , 10 hours ago

-

RE: Our Experience installing a heat pump into a Grade 2 Listed stone house

@robs Do you need IAT for this to work? Don’t curren...

By Travellingwave , 12 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

@goodbyegas Hi Fellow Ecodan owner here. Looking a...

By Travellingwave , 13 hours ago

-

RE: Say hello and introduce yourself

You can send private messages via the Messages (envelop...

By cathodeRay , 16 hours ago

-

RE: Peak Energy Products V therm 16kW unit heat pump not reaching flow temperature

With complete radio silence from Peak and no sign of th...

By DaveC , 16 hours ago

-

RE: The Hidden Secret to a Successful Heat Pump: Pipe Size Matters

I'm wondering if I need to do any pipe upgrades. My hea...

By Falesh , 18 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred The Pace BMS also isn't the best with it's ...

By Bash , 18 hours ago

-

I understand now what you were referring to. This look...

By trebor12345 , 18 hours ago

-

RE: What determines the SOC of a battery?

@batpred I would consider changing your balance star...

By Bash , 19 hours ago

-

RE: Setback savings - fact or fiction?

This illustrates what I am getting at, even apparent st...

By cathodeRay , 23 hours ago

-

No you arent, because you dont need any, and furthermor...

By JamesPa , 24 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

As I mentioned earlier most radiators have a power outp...

By JamesPa , 1 day ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 2 days ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 3 days ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 3 days ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 3 days ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 3 days ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 3 days ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 3 days ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 3 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 3 days ago