@cathoderay I'll put something together about pump curves and system curves.

But to help you, I suggest the following:

Open all the TRVs and lockshield valves fully on your radiators now, don't wait for a cold snap. Your data logger is grabbing data and if / when it gets cold again we'll see the difference.

If it's successfull we'll see your ASHP operating at higher power outputs, this will be the main indicator the change has been successful. Monitoring the temperature difference between primary_in and secondary_out around your PEX will be a secondary check.

If I was doing this at work I would be installing pressure gauges on the pipework to measure the system hydraulics, but we can't do that. What we'll do insted is observe how the system operates over a long period and see if it's getting more energy into your house.

Regards

Bob

Posted by: @bobtskutterI'll put something together about pump curves and system curves.

Thanks, that will be very useful. I rather suspect the flow side of things doesn't get the attention it deserves, and is generally rather poorly understood.

Posted by: @bobtskutterOpen all the TRVs and lockshield valves fully on your radiators now, don't wait for a cold snap. Your data logger is grabbing data and if / when it gets cold again we'll see the difference.

If it's successfull we'll see your ASHP operating at higher power outputs, this will be the main indicator the change has been successful.

But in mild to moderate OATs my heat pump/system can manage, and it seems to me that if there is no deficit in these conditions, then we won't see any change, because there is no deficit to be made up. We know it can manage, because the IAT is where it should be. Nonetheless I will open the lockshields (TRVs are already fully open, have been from day one), probably tomorrow as I have a rather busy day today.

Meanwhile, here's another thing I struggle with (but still very pertinent). The heat transfer equation

kW = flow rate x flow/return delta t x specific heat capacity of fluid

means the heat transferred is proportional to all three terms on the right hand side of the equation.

The specific heat capacity of the fluid is fixed (4.2 because it is water), but the other two can vary. However, the flow rate and the flow/return delta t are not independent of each other. If I increase the flow rate, the flow/return delta t decreases (less time for the heat to move across). I don't know what the relationship between the two is, but imagine that if you double the flow rate, then the flow/return delta t halves. In that particular case, you are stuffed: the increase in flow rate is cancelled out by the drop in flow/return delta t. Likewise if you halve the flow rate, the flow return delta t doubles, and the two cancel out again. If I could directly control the flow rate I could simply vary it and see what happens, but I can't. But I can observe that when working very hard my heat pump (this is primary circuit not secondary circuit) does achieve bigger flow/return delta t values (perhaps twice normal), while at the same flow rate drops by about a third for some of the time. What's going on here? Is the heat pump counter-intuitively dropping the flow rate to increase heat transfer because the change in flow/return delta t is proportionately larger than the drop in flow rate:

normal running: flow rate = 1.4, flow/return delta t = 4, 1.4 x 4 = 5.6

hard running: flow rate = 1.0, flow return delta t = 8, 1 x 8 = 8

ie paradoxically (given the equation) you have to drop flow rate to increase heat transfer - or is that complete nonsense?

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayIf I increase the flow rate, the flow/return delta t decreases (less time for the heat to move across). I don't know what the relationship between the two is, but imagine that if you double the flow rate, then the flow/return delta t halves. In that particular case, you are stuffed: the increase in flow rate is cancelled out by the drop in flow/return deltat

Correct. However you are looking at this from the wrong direction. The loss from radiator to room is dependent on the flow temperature. This you can change. The deltaT then follows from the flow rate and the loss.

If you increase the flow rate deltaT will reduce which will slightly increase the average radiator temp, thus increasing the loss. That's a second order effect although it's the one used when you balance radiators. The principal way to change the the heat emitted by the totality of the radiators is to change the flow temperature.

At the heat pump end it just adjusts it's power to restore the returning water to the desired flow temperature.

Think of this as driven by the radiators not the heat pump.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Hello All,

I'm conscious I've turned up on the forum and am writing these long posts full of apparent technical detail. I've been troubleshooting heat and material balance problems for almost 25years, but on a much larger scale.

Heat and material balance problems are often a circular calculation. You have to make an assumption, work round the calculations and try to validate your starting point. If you can't validate the starting point you need to ask yourself "what else would need to change to make it balance".

The basic equation for heat and material balancing is:

In = Out + Accumulation

That "Accumulation" term is what catches a lot of people out so we need be aware it exists, but carry out our data analysis in a way in which we can ignore it. We need to look at data in small time frames, per second if possible.

This is where we can get confused between Energy and Power. Power is Energy per Unit of Time, kW = kJ/s, if we're looking at data over a 1second period then Energy and Power are the same thing. I know that's confusing if you've only got data from your data logger every 1min or every 5min. Just bear with my rather long winded explanation.

There are two basic equations in use for heat transfer in heating systems:

Q = M.Cp.DT

Q = U.A.DT

Q = Energy kJ

M = Mass kg

Cp = Specific heat of water = 4.2 kJ/kg/C

DT = Change in temperature C

U = Heat transfer coefficient kJ/m2/C

A = Area for heat transfer m2

There are also some engineering assumptions going on:

* There is no phase change going on, it's always liquid water.

* There are no changes to physical properties, the density is always the same.

* Energy content of an object is relative to a point where it doesn't have any energy, which is at absolute zero degrees Kelvin. The Q term in the equations above means "the energy required to change the temperature by DT".

* Water has a density of 1kg/L so if we have a flow in L/s (litre per second) we have 1kg/s and then we also have Q in kJ/s, which is kW.

You can calculate the ASHP power output by using:

Q_ASHP = M_Prim.Cp.(LWT-RWT)

In cathoderays case, the power from the ASHP has to flow through a Plate heat exchanger (PEX) before it can get to the radiators.

For a heat exchanger we use:

Q = U.A.DT

in this case DT is the temperature difference between the hot fluid and the cold fluid. But the fluid temperatures are different at different points in the PEX, so we have to use an "average DT between hot and cold fluid". Technically we should be using Delta Temperature Log Mean (look it up via wikipedia) but we can simplify in this case to using Average_DT because the PEX is small and will have a good heat transfer coefficient.

Average_DT = ((T_Prim_In - T_Sec_Out) + (T_Prim_out - T_Sec_out)) / 2

[Assuming the PEX is piped up in countercurrent flow].

So

Q_Transfered_through_PEX = U.A.(((T_Prim_In - T_Sec_Out) + (T_Prim_out - T_Sec_out)) / 2)

If we make an assumption that the system responds instantly, all the energy flowing out of the ASHP flows through the PEX (we ignore any accumulation in the metalwork of the heating system).

Q_ASHP = Q_Transfered_through_PEX

But we can also apply Q = M.Cp.DT to the primary and secondary sides of the PEX

Q_Prim = M_Prim.Cp.(T_Prim_In - T_Prim_Out)

Q_Sec = M_Sec.Cp.(T_Sec_In - T_Sec_Out)

What we end up with is a bunch of equations which are all equal:

Q_ASHP = Q_Transfered_through_PEX = Q_Prim = Q_Sec

If I choose

Q_ASHP = Q_Sec

M_Prim.Cp.(LWT-RWT) = M_Sec.Cp.(T_Sec_In - T_Sec_Out)

But there's an added complication in cathoderays system, the PEX is pinched on the outlet to the seondary circuit, which means:

LWT = T_Sec_Out

So...

M_Prim.Cp.(LWT-RWT) = M_Sec.Cp.(T_Sec_In - LWT)

There are a few (hidden) assumptions in these equations.

* The PEX has enough surface area to be able to transfer all the heat from the ASHP. I believe this is the case looking at the dimensions cathoderay has provided.

* The rads have enough surface area to dissipate all the heat from the ASHP. I believe this is the case, especially considering the Midea data sheet says the ASHP can output an LWT of 55C and cathoderay has said the rads are K3 type (lots of heat transfer area).

If we want to make the ASHP put out more power, the whole left hand side of the above equation needs to go up which means the whole right hand side of the equation must go up.

How do we make M_Sec.Cp.(T_Sec_In - LWT) go up?

Lower T_Sec_in? That means we need to get more power out of the radiators. Bigger rads? Not very practical.

Lower LWT? That's not going to help because it will lower the ASHP output power (it's part of the left hand side of the equation above).

Increase M_Sec? That means increase the flow in the secondary circuit, which we should be able to do.

How do we increase the flow in the secondary circuit?

Make the pump spin faster. Cathoderays secondary pump is already at max speed, so there's no adjustment.

Reduce secondary circuit pressure drop. Open all the valves on the system, TRVs and lock sheild valves.

Fit a bigger pump, not very practical.

Hopefully this explains why increasing secondary circuit flow will increase the power output of the ASHP.

Regards

Bob

Something else crossed my mind when I posted on a discussion about the order components should installed.

You mentioned you reversed the direction of the secondary pump to make the PEX operate in counter current flow.

Please you show the order the components are installed in the secondary circuit.

eg.

Pump discharge > radiator inlet > radiator outlet > mag filter > plate_inlet > plate_outlet > pump suction

It could be the magnetic filter is in the wrong place (because the flow is reversed) and the plate exchanger is acting as the system filter.

Please can you post the details of the system filter, if it's a cyclonic design it will have a specific flow direction.

Regards

Bob

A brief explanation of reading vendor pump curves.

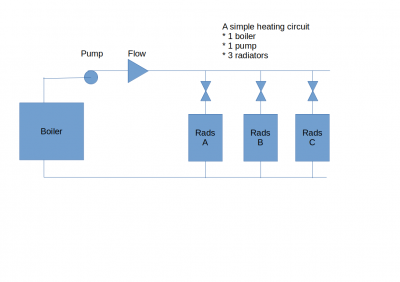

Here's a simple heating system. It's got 3 radiators, each one can be turned on or off separately (3 zones if you like).

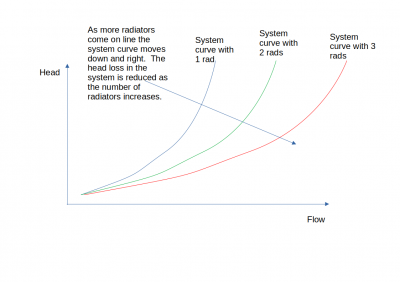

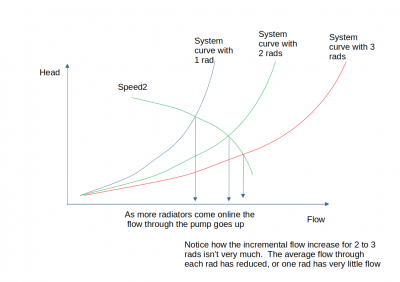

As the flow through the system increases, the head required to push the liquid through the radiator increases. This is called a system curve. As more radiators come on line, the system has less resistance to flow, to you get more flow for a given head. BUT, the system still responds with a "system curve". Please see the three different curves in the drawing below:

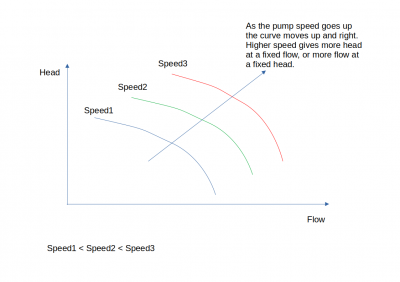

A pump adds differential head to a system. Head is a measure of energy and if we know the fluid density we can convert to pressure. Head and pressure are often used interchangeably. The next drawing shows how the pump curve varies with changing speed.

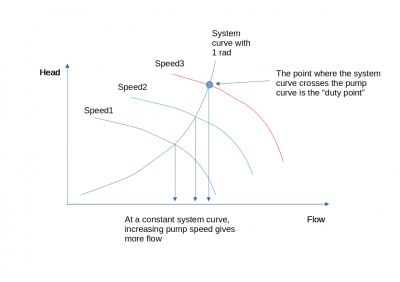

However, the pump will add as much head (pressure) to the system as the downstream system can handle. So whilst a pump curve tells you what a pump CAN do, you need to overlay the system curve to know what it ACTUALLY does.

The point at which the system curve and pump curve have the same head, tells you the system flow. This is called the duty point. For a given system (e.g. one radiator) increasing the pump speed will increase the flow. If you modify the downstream system to reduce resistance to flow (by opening the valves to rads 2 and 3), you'll get more flow. The duty point MUST sit on one of the pump curves, it can not be higher or lower than the pump curve. So if you know the flow through the system and which pump curve you're using, you also know the head loss through the system.

Notice how the increase in flow from 1 to 2 radiators is quite large, but the flow increase from 2 to 3 radiators is quite small. This means the AVERAGE flow through each radiator goes down as you add more radiators to the downstream system.

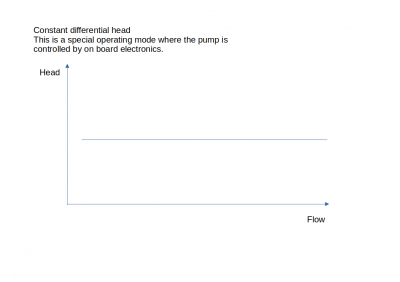

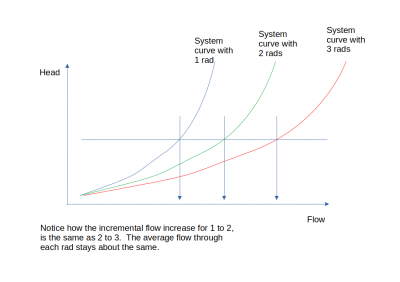

This isn't an ideal situation for people with multiple zones, or multiple underfloor heating circuits. So some heating circulation pumps have a special operating mode called "constant differential head". This is a straight horizontal line on the pump curve.

This operating mode uses electronics in the pump head to work out what the differential head actually is in the system. It's actually an automatic feedback control loop inside the pump that monitors the system differential head and changes the speed to keep the differential head constant. It does not use a pressure sensor, it's all done by tracking rotational speed of the pump impeller.

The result is you get a bigger increase in flow (through the pump) as more radiator circuits come on line. Which means the average flow through each radiator stays about the same.

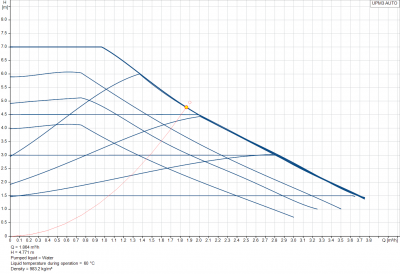

Here's a pump curve chart from Grundfos:

It might seem confusing at first, but it's showing you the different operating modes at each of 4 different pump speeds.

You can see the curves of head vs flow for 4 different speeds.

You can see the horizontal lines of constant differential head for 4 different set points.

You an also 3 curves where differential head varies in proportion with flow. I've not explained this mode of operation but it's another control mode to add flow to the system when the downstream resistance is reduced.

You can see the red system curve and the yellow dot is the duty point when operating in fixed speed mode at the highest speed.

The most important thing to notice on the pump curve is all the operating modes can only put out as much flow as the maximum pump speed.

I hope this helps

Regards

Bob

@bobtskutter - thanks for your posts which I will go through with great interest.

In the meantime, I opened all lockshields all the way a couple of hours or so ago. Current OAT (from the heat pump) 3 degrees, set to get colder.

Here's the order of components in the secondary circuit:

Return from rads > circulating pump > magnetic filter > PHE > out to rads

Midea 14kW (for now...) ASHP heating both building and DHW

@bobtskutter - sorry, forgot to add, the magnetic filter is a FloMasta Magnetic Filter, Product No 2034V. Apparently (according to an online Q&A, it is bi-directional...). Also 22mm, a bit small to be in a 'main run'?

Midea 14kW (for now...) ASHP heating both building and DHW

Hello,

Sounds like the flow goes through the magnetic filter before it gets to the PEX, so that's good.

22mm and 1.8m3/hr is about 1.3m/s. I think people normally design domestic pipework for 1m/s to keep the noise down. Personally that doesn't seem too bad a number to me.

Using this website https://www.copely.com/tools/pressure-drop-calculator/ I estimate 60m of 22mm copper pipe to get 47kPa pressure drop. If you where to estimate the total length of the pipe work in your house do you think it would be 60m?

I saw the reply about the lock shield valves, keep an eye on the heat pump output power to see if it gets over 8.4kW.

You may have it all ready...

Flow(m3/hr)*1000/3600*4.2*(LWT-RWT) = power(kW)

You might be able to build a calculation into your data logger for it.

Bob

@bobtskutter - I think we may be onto something! But first a quick bit of housekeeping.

Posted by: @bobtskutterSounds like the flow goes through the magnetic filter before it gets to the PEX, so that's good.

That's correct.

Posted by: @bobtskutterI saw the reply about the lock shield valves, keep an eye on the heat pump output power to see if it gets over 8.4kW.

You may have it all ready...

Flow(m3/hr)*1000/3600*4.2*(LWT-RWT) = power(kW)

You might be able to build a calculation into your data logger for it.

The calculation is already in there, used to calculate the kWh out on my standard charts. I have one python script that collects the raw data once a minute and puts it into a csv file, and then another one that runs once an hour that extracts the last hour's data from the minute data file and among other things calculates the trailing energy in and out for the last hour (so the bar on the chart at say 0600 is the energy in and out from 0500 to 0600). The hour data then ends up in its own hour data csv file (and then I use plotly to generate the charts from those csv files).

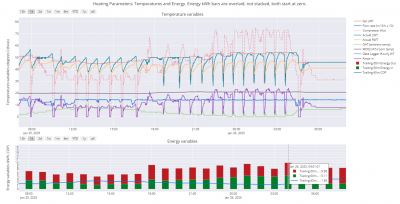

Here is the standard chart with some extras (omitted on the standard chart to reduce clutter) for the last 24 hours. The lock shield valves were opened at 1730 yesterday. It was then 'usefully' cold last night. The heat pump used regular defrosts overnight and then went into steady state at about 0430 this morning. This is all normal behaviour consistent with the OATs over the period:

Result! Look at the value of the energy out bar at 0400 this morning! 9.98kWh!

The house is also notably warmer this morning. However, the rads aren't exactly balanced, some are very warm, others are distinctly cool (the usual suspects, mostly the ones at the end of a run). The rooms are a bit more balanced, presumably air flow between rooms.

This now begs the question: how to balance the system without choking it?

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay May I suggest a slowly-slowly approach? Start by shutting just one or two of the LSV’s in stages; these should be the ones in rooms that are the most ‘overly’ warm. This will result in the cooler ones on the end of the run being able to receive a little more of the share out. Just in case you haven’t come across my article:

https://renewableheatinghub.co.uk/how-to-balance-radiators-the-role-of-the-lockshield-valve

Just a suggestion… Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

Posted by: @toodlesJust a suggestion… Toodles.

Appreciated, thanks. I do in fact use your approach. The problem I think I am coming up against is the rads at the ends of both the ground and first floor pipe runs are very reluctant to get warm, to get them to warm up I have to do some pretty brutal lock shielding on other rads. I don't think there are any blockages - the system had a very serious power flush at the time the heat pump went in, and there are minimal deposits in the filter when I clean it.

Midea 14kW (for now...) ASHP heating both building and DHW

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 348 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 13 minutes ago

-

RE: Electricity price predictions

Sorry to derail this thread ‘slightly?’ but back to the...

By Toodles , 22 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Without knowing it, @andrewj, you've laid down the gaun...

By Majordennisbloodnok , 41 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 46 minutes ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 1 hour ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 2 hours ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 2 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 4 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 4 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 6 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 10 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 20 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 22 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago