Hybrid ASHP System: Vaillant AromaTHERM Plus 12 kW with Bosch Danesmore 18/25 oil boiler

@editor Hi, we are in Kinross-shire and have just completed installation of a hybrid ASHP/oil system. House is off-grid for gas, 4 bedrooms, single storey and built between 1970 and 1990. ASHP is a Vaillant AromaTHERM Plus 12 kW with a new Bosch Danesmore 18/25 oil boiler as topup via a buffer tank. This all replaces a 23 yr old 50-70 kW oil boiler. We added 150mm of loft insulation to what was there, replaced decaying 197x vintage double glazing and plugged most of the draughts. We have cavity insulation but there is no access under the suspended floors and only 50 cm clearance so underfloor insulation would involve serious ripping up of floors.

Heat calculations indicated about 17 kW heating load on the coldest days hence the small auxilliary boiler so why the original boiler was this large is a mystery. We installed a Hive system 2 or 3 years ago which recovered its cost by allowing me to keep on top of the system but is now redundant except for controlling one smart TRV which we have left in.

8 out of 20 radiators needed upgrading but the deeper K3 radiators just went in one-for-one without trashing decorations or needing to move pipes.

I have a software engineering background so of course my instinct is to climb all over and inside how the new system works, not easy. Like other contributors here I have a bunch of Govee thermometers recording the room and external temperature and I'll be installing a bunch of WiFi temperature sensors on the various flow and return pipes and possibly a couple in the fan unit airflow. I can monitor it all with HomeAssistant.

This week I'm getting my head around it all, reading the forums :-), struggling with the MyVaillant app and I'm waiting for OvO to come back to me to move forward with their heat pump tariff. Costs otherwise look a bit high. Conscience not cost was the main motivation since our old system was generating about 10 tonnes of CO2 per annum. We had grant support for this and a condition was to get a new EPC certificate. The house has gone from 'E' to 'C', mostly because of the heat pump which is good news.

My grandly renamed plant room (formerly the boiler room) is now full-on Monty Python with pipes everywhere.

@dr_dongle If you wish to consider underfloor insulation, Q-Bot can use a ‘robot’ to spray under the floor with just 200 mm of clearance https://q-bot.co

Not cheap but we had ours done about 3 years back and have found it beneficial. They can gain access through a small hatch or create one for you if required and they are very tidy workers. They created an access trap in our understairs cupboard and left everything very tidy afterwards. Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

@Toodles That's very interesting to hear, thanks. I had seen their adverts but experience of underfloor voids with their usual quota of holes, bumps and builders' detritus made me sceptical. There is also the issue of sleeper walls and external walls that are now internal. (this house was built in stages and totally remodelled at least once). That's not a reason not to give them a a chance though - anything is better than large scale floor ripping!

@dr_dongle Living as we do on a hill, one side of our property has a deeper void than nearer the party wall. I think it is probably 400-500 mm. near the party wall and a full metre on the side where they created a trap. In our instance, the chaps were eager to donn a ‘spacesuit’ and go intrepidly down the ‘ole and carry out the spraying ‘mandraulically’ so the robot was able to have a rest. We were shown the robot buggy complete with caterpillar tracks and very powerful traction to cope with builder’s err … indiscretions etc. and we were provided with before and after photos too. We also have a ‘sustificate’ for the work should we ever need to justify the quality of the work to anyone. Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

I was interested after reading this but they can only do this with wooden floor boards if you have chipboard it’s not suitable.

“Anything worth doing, is worth doing right.”

@irmartini Oh! That’s a great shame.😳 Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

@editor Hi - An update to my earlier introduction

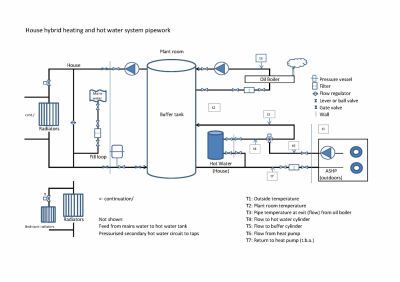

Our hybrid ASHP / Oil boiler system went in in April and has been doing its thing without major issues since then though the real test will come in when we get into winter. You can see the layout and schematic in the attachments - either heat source can feed the buffer tank which then delivers hot water to the radiators, alternatively the ASHP can heat the hot water cylinder directly (though not the oil boiler, a condition of the grant).

The little yellow box monitors temperature sensors t1-t7 on the pipes and outdoors (I have other thermometers around the house and nearby) and reports to HA. I will be installing power monitors on the two pumps then I'll be able to see exactly what the system is up to. I've already discovered a couple of oddities and discovered that the Vaillant reference thermometer is not in the best place.

All pumps are normally under the control of the ASHP controller but I have installed a changeover switch which lets me fire up the oil boiler and pump manually - normally the boiler would only come on when the outside temperature goes below the bivalent point.

Moving from oil to ASHP as our primary heat source lifted the house from EPC energy class 'E' to class 'C' which is a good start and rebates from the heat pump tariff are coming through as hoped-for.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 638 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

That’s my pleasure, @andrewj. The only challenge now is...

By Majordennisbloodnok , 2 hours ago

-

RE: Electricity price predictions

@toodles @skd Then there is not going to be much from t...

By ChandyKris , 2 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred I reckon Andy might know a thing or 2 about...

By Bash , 3 hours ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 4 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 4 hours ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 4 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 4 hours ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 4 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 5 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 9 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 12 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 13 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 2 days ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 2 days ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago