How not to install a heat pump

My heat pump was due to be installed in January after I had completed installing my underfloor heating and had got the floor tiling done. It all came off the rails when my tiler did his back in and rather than finishing before Christmas, he hadn't laid a single tile. By then the next available installation was the 3rd week of March and I thought I would get bored waiting, but no, my tiler didn't finish until the week before, leaving me with one week in which to do about 5 weeks' work. It was impossible so the heat pump was installed with 3 underfloor heating loops out of 14 not yet laid. This has turned out to be a blessing in disguise because it has left me with access to instrument the system to the nth degree.

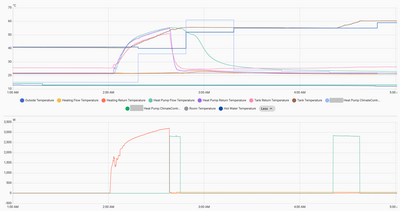

I was planning to install Home Assistant anyway, but as soon as the installer left I sensed things were not right, and so it is. On Friday this week my heat pump hit a new low with COP of about 0.7 for water heating. I have installed 6 temperature probes and 3 CT clamps to measure the performance of the system, and it bears little relation to what the heat pump reports itself. The pump only reports whole kWh of electricity used, whenever a full kWh is accounted for, whereas I need energy to be accounted for at the tariff in effect at the time it is used. That's evidently too much to expect!

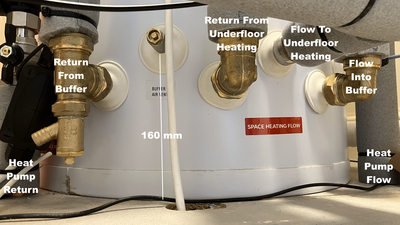

Setting aside the contractual issues, warranty issues, and failure to honour the payment terms, the elephant in the room is that it was agreed that the buffer tank built in to the pre-plumbed hot water cylinder that was used would be configured as a volumiser on the heating return, but it has definitely been plumbed in as a buffer tank, and one small circulating pump is expected to supply my 14 underfloor heating loops. With only 11 loops installed, the highest achievable flow rate on my longest loop is 4 litres per minute, and the pump is noisy because it is working flat out and is running for many hours after the heat pump unit has stopped providing heat. My manifolds came with their own circulating pumps so just by using those pumps instead, the total flow could have been roughly doubled, but they were taken off on the understanding that the heat pump unit's pump would supply the whole system and I was pleased with the promise of the pump being outside and thus having virtually silent heating.

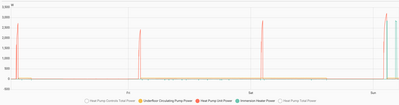

This is what today's disinfection cycle looked like. I've worked out that the heat pump cuts out when the water cylinder reaches 53C and it then uses the immersion heater to get to the "comfort" setting of 55C, before going on to use it again to get to the 60C disinfection temperature. Obviously the COP drops to 1.0 as soon as direct heating is used. Moreover, note that even though the central heating did not come on, the circulating pump came on and ran for hours.

The COP on Friday was terrible because the circulating pump ran for the rest of the day. As you can see, it continued running until Saturday afternoon, and it only stopped then because I'd had enough and reset everything by turning it off and on again.

The water heating recorded 1 kWh and the circulating pump racked up 1.2 kWh. In terms of cost it was far worse: the heat pump cost 5p to run to do the actual heating, the circulating pump cost 33p, making the total cost 38p for a 6C increase in the hot water temperature. I'd have been far better off with either just an immersion heater or the gas boiler!

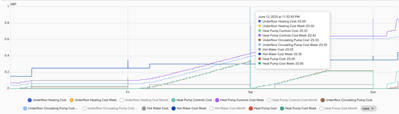

It's not heating season, but my observation when forcing the heating to run is that the flow temperature to the underfloor heating is always less than the return temperature to the heat pump. How is such inefficiency introduced by a buffer tank?

I'm going to add to my post as a separate comment later, as my laptop has ground to a halt and needs a reboot…

Closing remarks on the hot water heating. Even though the heat pump only reports whole kWh of energy consumed, it should have reported the energy used by the circulating pump as it was over 1 kWh but it did not. It evidently ignores the circulating pump's consumption. For the whole of May the overall hot water COP based on the heat pump's own energy consumption and transfer measurements was 1.6. For Friday, only 1 kWh out of 2.2 kWh energy consumed was accounted for, so the actual COP was about 0.7.

Although it is not the heating season, I recalled that it had taken about 30 hours of continuous operation for my heat pump to get my home up to temperature when it was commissioned on 21st March, and although I appreciate fully that the heating is supposed to be slow and gentle, one doesn't expect it to take over a day to get warm after returning from a holiday, or in this case, heating my home about 96 hours after the gas boiler had been removed.

To test the heating, with the sensors added, I turned off the overnight hot water cycle and set the heat pump the space heating target of 21C during the overnight off-peak electricity period instead. The room temperature started at 19.8C, so only a 1.2C rise was needed, which the sun can exceed easily in a couple of hours on a sunny day. Needless to say, it failed, raising the room temperature by just 0.5C in the 2 hours. Here are my measurements:

Rounding the decimals, since the heat pump only reports full degrees Celsius, the water entering the un-zoned underfloor heating is 7C cooler than the water leaving the heat pump. The water leaving the underfloor heating is only 0.7C cooler than when it entered, suggesting that the heat transfer efficiency through the unwanted buffer tank is just 0.7/7.7 = 9%. This hopeless situation appears to be reflected in the power drawn by the heat pump, which resembles a fine toothed comb, oscillating between about 250W and 550W. I'm guessing this is what cycling looks like.

My underfloor heating manifolds each came with a circulating pump, but they were taken off on the understanding that the circulation would be driven by the heat pump itself and the buffer tank integrated into the bottom of the pre-plumbed hot water cylinder would be configured as a volumiser on the return to the heat pump. Instead of having 2 circulating pumps for the 14 underfloor circuits, there is just the one mounted on the cylinder, and with the flow control valves throttled right down on the shortest loops to the towel rails, shower room, bath room, utility room and cloakroom, the maximum unrestricted flow through the longer loops is only 4 litres per minute. My underfloor pipework has an internal diameter of 11.5mm, giving a volume of 1 litre for every 9.6 metres of pipework laid. It's close enough to calculate my underfloor heating volume as 1 litre per 10 metres of pipe. My longest runs are over 80 metres, so with this flow rate a water change takes over 2 minutes and the typical ones are 60 to 70 metres, which means a water change takes over 1.5 minutes. The total underfloor pipe length is about 660 metres, thus has a capacity of about 66 litres. From this, it is self-evident that the heat pump is cycling more frequently than the water is changing in the underfloor heating. Surely this is utter nonsense?

My heat loss calculations are about 3 kW, and the heat pump is rated at 4 kW. I don't know what the minimum system volume is for a 4 kW heat pump, but all pipework is 28mm, with a volume of about 1 litre per 2 metres of pipe. That gives a total volume of about 75 litres for the underfloor system, about 15 litres for the heat pump flow and return pipework. Does the buffer tank even need to be configured as a volumiser, or is it completely unnecessary?

Lastly, if you've read this far without losing the will to live, a video for your entertainment. Exchanging the hot water cylinder introduced hammering when the first hot water tap is opened after a water heating cycle. I recorded this at 102 dB, easily loud enough to startle and wake up anyone who is still sleeping. The installer came back and added a tiny expansion vessel close to the hot water outlet from the cylinder. This video shows what it sounds like now. No special effects have been added! https://youtube.com/shorts/29AAeSHsIVw

Sorry to hear about your problems, which your installer should be fixing however...

Posted by: @sandvikaand the buffer tank integrated into the bottom of the pre-plumbed hot water cylinder would be configured as a volumiser on the return to the heat pump.

has it been configured as a volumiser or is it still a buffer tank? There appears to be a 5C difference between heat pump flow and heating flow, there should be minimal temperature difference!

Are there any restrictions in or bypass to the UFH. It looks, from your temperatures, possible that very little water is actually flowing through the UFH which can only be because of a restriction, bypass, or because the pump isnt turned up.

Posted by: @sandvikaMy heat loss calculations are about 3 kW, and the heat pump is rated at 4 kW. I don't know what the minimum system volume is for a 4 kW heat pump, but all pipework is 28mm, with a volume of about 1 litre per 2 metres of pipe. That gives a total volume of about 75 litres for the underfloor system, about 15 litres for the heat pump flow and return pipework. Does the buffer tank even need to be configured as a volumiser, or is it completely unnecessary?

Probably not, but a volumiser (plumbed either in the return or (better) in the flow NOT between the two) will do no harm so, assuming its been correctly plumbed this is not the problem.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @sandvikaLastly, if you've read this far without losing the will to live, a video for your entertainment. Exchanging the hot water cylinder introduced hammering when the first hot water tap is opened after a water heating cycle. I recorded this at 102 dB, easily loud enough to startle and wake up anyone who is still sleeping. The installer came back and added a tiny expansion vessel close to the hot water outlet from the cylinder. This video shows what it sounds like now. No special effects have been added! https://youtube.com/shorts/29AAeSHsIVw

er, the plumber needs to revisit and do the job properly.

"Never time to do it right, always time to do it twice!"

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaSorry to hear about your problems, which your installer should be fixing however...

...

has it been configured as a volumiser or is it still a buffer tank? There appears to be a 5C difference between heat pump flow and heating flow, there should be minimal temperature difference!

Posted by: @sandvika... Does the buffer tank even need to be configured as a volumiser, or is it completely unnecessary?

Probably not, but a volumiser (plumbed either in the return or (better) in the flow NOT between the two) will do no harm so, assuming its been correctly plumbed this is not the problem.

Thank you, James. The installer has received the BUS grant but is not expecting my payment until the issues have been resolved. I think I'm lucky that I don't need the space heating right now.

It was agreed on the first day of the install that the buffer tank would be plumbed as a volumiser on the return, which I understand to be common practice. However, just reading up about it, there doesn't appear to be a particular reason for having it on the return, whereas having it on the flow mitigates against very cold water entering the system at the start of a defrost cycle.

Since it was actually plumbed as a buffer, and remains that way presently because the installer now maintains that it is correct, it would entail a trivial modification to the plumbing to remove the buffer and circulating pump from the return loop, whereas it would involve two separate modifications to remove the buffer from the flow and the circulating pump from the return. Based on the defrost cycle benfit, I would settle for it remaining on the flow and just making the one modification to the return.

Posted by: @sandvikaIt was agreed on the first day of the install that the buffer tank would be plumbed as a volumiser on the return, which I understand to be common practice. However, just reading up about it, there doesn't appear to be a particular reason for having it on the return, whereas having it on the flow mitigates against very cold water entering the system at the start of a defrost cycle.

You are right. Thinking on this has evolved over the past 12 months following a lengthy discussion on this forum where we went through lots of different arguments. The current view, at least on this forum, is that a volumiser is best on the flow, Im not sure whether a conclusion was reached about whether it should go before or after the diverter valve, the thread is here

Posted by: @sandvikaSince it was actually plumbed as a buffer, and remains that way presently because the installer now maintains that it is correct, it would entail a trivial modification to the plumbing to remove the buffer and circulating pump from the return loop, whereas it would involve two separate modifications to remove the buffer from the flow and the circulating pump from the return. Based on the defrost cycle benfit, I would settle for it remaining on the flow and just making the one modification to the return

Firstly thanks for confirming it is still plumbed as a buffer, which certainly could explain what you observe with the system. It needs to change!

You ideally want to use (if it becomes a volumiser) an input port at the bottom and an output port at the top to ensure that its properly at temperature, which slightly complicates the replumbing, although it looks from your picture that there is not really a top and bottom, its an incredibly squat buffer, so I doubt it will make much difference!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Now that issues have been addressed, I'm no longer coy about who the installer was, or what the heat pump is. The installer was British Gas and they deferred their invoice whilst the problems were being resolved. The heat pump is a Daikin Altherma 4kW monobloc unit. The issues were fourfold:

1 - The plumbing as a buffer tank clearly caused the cycling of the heat pump. Now that it has been replumbed as a volumiser this has ceased. Daikin require the volumiser to be plumbed in the return, for unspecified reasons best known to them, so this has been done. This raises serious design concerns about Daikin's pancake-shaped buffer tank, that prevented proper stratification of the feed and return, with the space heating loop running at a markedly lower temperature than the heat pump loop. This issue will surely affect all other installations where this design of cylinder is used as a buffer, and be profoundly detrimental to the performance of the system.

2 - The operation of the now removed circulating pump was water temperature controlled and was adjusted on the tank, not on the heating control panel, and it ran independently of the heat pump! It had not been set appropriately during the installation and happened to be at 21C. Thus, as soon as the ambient temperature in my home reached 21C because of insolation and proximity of the sensor in the buffer tank beneath the hot water cylinder it is integrated with, the pump started running 24x7, totally negating all benefits of the heat pump. This was a simple installation error and failure to configure, but not at all obvious.

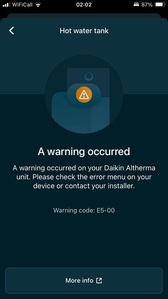

3 - The heat pump suffered a total failure, but reported only a warning, at which point water heating was only provided by the immersion heater upon request ("powerful heating" mode) and this became a Daikin warranty claim. The Daikin Onecta app and system were totally useless in reporting this as "A warning occurred", resulting in a perfectly good main PCB being replaced in my heat pump with no change of symptoms. The next proposed step was to replace the compressor, but the engineer sent by Daikin said that was more work than replacing the unit and since it was essentially brand new, I advocated through British Gas that such a profound early life failure would warrant complete replacement otherwise it risked the system becoming a "lemon". Fortunately, it transpired that the code "E5-00" actually means the compressor has overheated which is why it is reported as a warning, not as a failure, in the expectation that it will cool down and clear itself, but the useless message made it impossible to deduce that it implied a fault with the thermistor since the system didn't operate at all. The thermistor, roughly resembling the 2-pin can types often used in tumble dryers, and costing about £10 each was replaced and it has been fine since. That's three engineer visits for one £10 component. I hope my replaced main board gets put back into the spares supply chain, not scrapped. This will surely have cost Daikin a substantial proportion of their profit on my heat pump.

4 - The pressure reduction valve was the cause of the hammer blow. It is provided as part of the installation kit for the cylinder and that is why British Gas replaced my perfectly good one with this new duff one. British Gas considered it also to be a Daiking warranty issue. Daikin considered it a part not covered by warranty. British Gas believed that it is factory pre-set and not adjustable, but in fact it is adjustable and if it is dismantled and reassembled without awareness of this, it is liable to be set to a different pressure after re-assembly. Consequently British Gas introduced a second issue of low water pressure - leading to it taking over 30 minutes to run a bath - without eliminating the hammer blow. The Daikin engineer was able to take it apart too, also find no fault with it, but then adjust the pressure with the taps running to achieve balanced hot and cold flow, and somehow this had the effect of the hammer blow reducing gradually without further intervention until it was no longer an issue. It seems like the valve needed to be worn in like a pair of hiking boots.

Revised system performance

The hot water cycle runs only between 2am-3am always using off-peak electricity and the sterilisation cycle occurs 4am-5am on Sundays, again using only off-peak electricity. The hot water programme alternates between "Economy" and "Comfort" cycles, the idea being that if my hot water usage is low, it won't necessarily be heated every night. "Comfort" cycles are adjacent on Sunday and Monday, the three "Economy" cycles are thus on Tuesday, Thursday and Saturday. Consequently if my hot water usage is low after the sterilisation cycle on Sunday, then water heating may not occur on Monday or Tuesday nights, as the tank temperature falls gradually from the sterilisation peak temperature. Last week, my total water heating bill was £1.02 including VAT.

The space heating schedule is on all 24 hours at 20C except, 3am-5am when the target is 21C (off-peak electricity boost period) and 4pm-7pm when the target is 18C (peak electricity demand suppression). The charts above show that the heat pump is no longer cycling and is instead just about achieving the temporarily higher target 21C within the off-peak electricity period, such that the space heating is currently achieved fully using off-peak electricity at 16.76p/kWh, that no heating is required at the standard rate of 27.93p/kWh. This is achieved with the water temperature presently leaving the heat pump at 41C maximum. The off-peak electricity price is exactly 60% of the regular price, or putting it another way, it's OK to accept a 40% performance penalty on the SCOP during this window to reap the benefits of the cheaper electricity. Last week, my total space heating bill was £6.06 including VAT.

The total electricity consumption last night was 4.69 kWh at a cost of £0.83 including VAT. I think this is very promising. However, Daikin only reports full kWh of electricity used, so daily measurements are meaningless. I'll need to wait until the end of the month to get my first proper COP estimates.

Delighted to hear that the buffer has been replumbed as a volumiser and other changes made. Please do post a further update and any questions as it gets colder.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

- 26 Forums

- 2,396 Topics

- 54.3 K Posts

- 368 Online

- 6,077 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Recommended home battery inverters + regulatory matters - help requested

To me that makes sense. Bond the inverter neutral to t...

By JamesPa , 4 minutes ago

-

RE: Power outages and storms: A surprisingly good DNO experience

To be fair, the interactions I’ve been having recently ...

By Majordennisbloodnok , 27 minutes ago

-

RE: Setback savings - fact or fiction?

As far as I am aware, the majority, if not all, of the ...

By cathodeRay , 2 hours ago

-

RE: Advice for a novice on Mitsubishi Ecodan 6kW

Fair point. The highest frequency of defrosts I'd seen...

By Sheriff Fatman , 13 hours ago

-

RE: Heatpunk Floor plan issues

It's usually the complete opposite... seldom that Safar...

By Mars , 13 hours ago

-

RE: RDSAP10 effect on existing heat pump EPC rating?

@mike-patrick interesting update - thanks.I've been thr...

By Tim441 , 14 hours ago

-

RE: Fan is clipping ice build up from the front of unit.

@majordennisbloodnok I’ll not go there thanks! Toodles.

By Toodles , 16 hours ago

-

RE: Running from backup generaor in powercut?

@majordennisbloodnok Back in the 80’ or 90’ we had a te...

By Toodles , 16 hours ago

-

RE: Running my new Nibe ASHP efficiently

I'm new to the forum. Did you get a reply to this last ...

By Mike @ Camelot , 17 hours ago

-

RE: ASHP Energy Consumption: Aira 12kW heat pump

@grantmethestrength MCS requirements for DHW capacity h...

By Toodles , 18 hours ago

-

RE: New Mitsubishi Ecodan 11.2kW installation - L9 errors and maybe more

Great to hear! I just figured this out a day or tw...

By anotherdaveuk , 19 hours ago

-

RE: Help me keep the faith with my air source heat pump installation

@adamk I'm observing my own system at low temperatures ...

By dr_dongle , 1 day ago

-

RE: Free Ecoheat Heat Pump Install

@deltona Yes older houses are problematic like that, bu...

By bontwoody , 2 days ago

-

RE: Radiator sizing sanity check

As I mentioned early on the cost of supplying and fitti...

By JamesPa , 2 days ago

-

RE: Electricity price predictions

Great point, one of the key ones in my chat with Octopu...

By Batpred , 2 days ago

-

RE: New Fogstar 15.5kWh upright solution

Let me point out that there are many Chinese suppliers ...

By Transparent , 3 days ago

-

RE: Weather compensation- why you should use it

@majordennisbloodnok — The Two Ronnies Mastermind sketc...

By cathodeRay , 3 days ago

-

Just realised that this image of the cylinder cupboard ...

By Sheriff Fatman , 3 days ago

-

RE: Rodents! A word of warning for heat pump owners

Two thoughts: 1: Let's ask @david-s if Primary Pro in...

By Transparent , 3 days ago