Is this a bad installation and is there something wrong with my Samsung heat pump?

@david999 where in the UK are you based?

Received a few messages from installers overnight about your case, and several think you 4way valve isn’t changing over properly, so you may want to raise with the installers when they come to check your system.

Get a copy of The Ultimate Guide to Heat Pumps

Subscribe and follow our YouTube channel!

A defrost that's taking far too long would suggest a faulty 4-port reversing valve. The valve is a pilot operated solenoid device, common in all reversible heat and cool refrigeration circuits. ASHPs in the UK only provide heat, but most can also cool by design, and they use the cooling mode to defrost the evaporator coil in winter, by reversing the refrigerant flow through the evaporator coil and condenser plate heat exchanger.

The defrost process is as follows:

1. ASHP compressor and evaporator fan stop

2. 4-way reversing valve energised

3. Compressor starts and frequency ramps up (after a short re-start time-out period)

4. Frozen condensate on evaporator coil melts as superheated refrigerant gas from the compressor discharge passes through it

5. Compressor stops, 4-way reversing valve de-energised

6. Evaporator fan starts (plume of steam from still warm evaporator coil)

7. Compressor restarts and frequency ramps up (after a short re-start time-out period and after the evaporator coil has cooled)

The ASHP circulating pump usually runs throughout.

The total time for the above is usually 5-10 minutes depending on environmental variables and ASHP make/model. Defrosting the evaporator coil should take no more than 2-3 minutes from the valve operation to the ice on the coil melting and running off as condensate into the unit drain. Hot superheated refrigerant gas passes through the evaporator, so the defrost often creates steam as well from the coil and from when the evaporator fan first restarts.

If the process is taking orders of magnitude longer - 30-60 minutes - the reversing valve is probably faulty. The coil will passively defrost if the outdoor air temperature is higher than freezing, but that will take much longer.

The evaporating temperature of the ASHP coil is always several degrees lower than the ambient air - it has to be lower to absorb heat [enthalpy] from the air passing through the coil. An electronic expansion valve controls the evaporating pressure and temperature. That's why you see ice forming on the evaporator at temperatures well above freeing point. The ice needs periodic defrosting as it eventually blocks the airways between the evaporator fins, preventing the refrigerant liquid from absorbing heat from the outdoor air and evaporating as is passes through the coil.

@allyfish I caught mine yesterday when it was like this and was able to time it. It would be 30 minutes before it started a defrost and completed it in about 4 mins or so. The outside temp about 5c. When it’s colder a lot more ice. Unfortunately I never caught it before so don’t know how long it was like that.

Posted by: @david999I caught mine yesterday when it was like this and was able to time it. It would be 30 minutes before it started a defrost and completed it in about 4 mins or so. The outside temp about 5c. When it’s colder a lot more ice.

Hi David, timing between defrosts varies based on outdoor temperature and humidity and how quickly the ice builds up. 30-60 minutes between defrosts is not unusual. That said, the ice build up as shown on your first photos looks excessive, it's extended onto the casing around the coil. It could have been a particularly cold and humid day? Defrost is usually quite quick, your controller will normally indicate when the unit is defrosting, as opposed to running normally. In colder weather the ice on the coil will build up gradually to a point where the unit senses it needs to defrost. It should do this before the coil gets completely blocked and no air can be drawn through it.

When in defrost you'll notice the leaving water temperature from the ASHP will start to cool, by how much depends on variables such as the target flow temperature set point, system volume, and atmospheric conditions - more ice on the coil needs more energy to defrost. ASHPs need a minimum volume of water on the secondary side, closing off radiators manually or with TRVs can adversely effect the system performance, much of the volume in the circuit is contained in the radiators not the pipework. When the radiator is closed off and has no flow, the volume inside is not contributing to the overall system volume. That's why radiators on ASHPs are best without thermostatic controls, or the thermostatic controls set full open and the system flow temperature used to control how much heat is provided.

The ice build up is gradual and slow, but the defrost should be quick - you'll see the ice melting rapidly and the evaporator coil might feel warm to touch. That's normal. If that's not happening, and the unit is taking far too long to defrost, then perhaps an issue with the ASHP? If the defrost is quick, but your radiators are dropping far too cold during defrost, or the target leaving water temperature is never reached, then the system water volume might be low. Open up all the rads in the circuit, give it a chance!

The ASHP could be short of refrigerant, which causes very low evaporating pressures and temperatures, but most modern units have sufficient control and monitoring to shut down in that case. They have very small refrigerant charge quantities anyway - refrigerant leaks tend to cause the unit to stop working. Refrigerant leaks are rare on newer hermetic monobloc ASHPs unless the unit has been damaged or mishandled.

It has been cold and damp around here, yesterday was +5 and damp all day, although not actually raining. We are over near Biggar so similar weather to Lanark.

I don't like the look of the pipes under the floor, they surely shouldn't sag and should be well insulated.

Posted by: @david999On the subject of pipe runs there are a great deal of radiators on the ground floor that are piped through the concrete slab floor. They drilled 22mm holes but not large enough to install insulation on the pipes. Will there be a marked heat loss here, the floor will be around 9 inches thick and how could you insulate this.

does the regulator have any pull over these companies or am I dependent on the installers good will to put it right and stuffed if they decide to walk away. The insulation is fairly poor but what you can’t see I guess and they don’t expect you to go under the floor. It’s certainly not cold under there.

Oh dear, oh dear!

Let's take this one point at a time.

1: Are you saying that they drilled 22mm holes vertically through the (suspended) concrete slab floor and then dropped 15mm pipes through each to feed the radiator above?

It could still be possible to use an expanding foam gun (or canister with a nozzle) to squirt into those holes.

That would at least stop free air rising up past the copper pipe.

2: Those pipe runs below the floor aren't adequately insulated.

I can't tell from the photo if the wall thickness of the grey Climaflex is 9mm or 13mm.

But either is too small for such a location.

I'd be using a 17mm-19mm wall thickness of closed-cell elastomeric nitrile-rubber

For a 15mm OD pipe, that's

Kaiflex STs2-T-2m-19x015-SA (2m lengths, slit with self-adhesive strip; 80m in a complete carton)

or Armaflex AF-4-015-A (2m lengths, slit with self-adhesive strip; 88m in a complete carton)

There are online "wholesalers" who will supply whole cartons direct to the public at good prices.

Yes, of course it's "not cold under there"!

It's being well heated by your pipe-runs 😣

3: I wouldn't be trying to fix the pipes using clips in this situation.

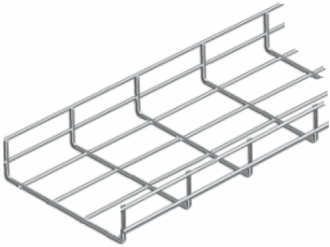

It's quicker/easier to hand a wire-rack style "cable tray" below the concrete floor and just drop the pipes into it!

Just because it's water-filled pipe rather than electric cables won't make this approach less suitable.

It means that the pipes are 100% covered by insulation, rather than have pipe-clips every so often.

4: As a wild idea...

There's an alternative approach of removing the nice new radiators...

clipping UnderFloor Heating pipe directly to the underside of the concrete slab...

... and then putting 100mm thickness of PIR (Polyisocyanurate) rigid insulation board directly below.

That gives you a 9" thick heated concrete pad 😎

Save energy... recycle electrons!

@transparent yes it is 22mm holes and I pumped foam in to stop the draughty holes, it was the same where they came through the wall from the pump, left it open.

As if it’s not bad enough I was under looking at those pipes and noticed that the beads that fill my cavity are falling out a hole in the brick. They were meant to be mixed with glue but clearly not. I remember the blokes having problems because it was so cold and the glue would not flow. Geez.

Here is a picture of my Samsung Gen 6 8kW yesterday evening. The outside air temperature was 3.5C, the relative humidity was around 90%, and the ASHP was producing around 4kW. A defrost cycle started 15 minutes after this and cleared all the frost in 5 minutes - the cycle was repeated at roughly hourly intervals through the evening.

Is it usual to see these clear bands in between the frost? I think I can see something similar at the top of the later picture from @david999

Here is a picture from early March showing a slightly different banding:

The 'banding' can be read as a bar-code which describes how well the defrost cycle is operating 🤔

Posted by: @david999I was under looking at those pipes and noticed that the beads that fill my cavity are falling out a hole in the brick.

Was the cavity insulation work from the same company as the heat-pump installation?

If they've proceeded to fill the cavity in a manner which they knew to be deficient, or outside the spec from the insulation bead manufacturer, then they're liable.

This would be covered by the Consumer Rights Act, and Trading Standards provisions.

If your house is covered by a mortgage or insurance, then those companies also 'have an interest' in the matter.

I have a relative whose house has just had deficient cavity insulation removed from an end wall at the expense of an insurer because the surveyor failed to identify the issue during the mortgage application. That work exposed the insulation in the two adjacent walls, which was found to be wringing wet. Stand by for round-2.

Save energy... recycle electrons!

your icing doesn’t seem to be as bad as mine and I’m thinking it needs an earlier defrost, perhaps there is a timer on it thats set too long, possibly the default setting because the installers just fitted and ran. Samsung thought too much ice but says the pump looks for several paramaters before starting a defrost.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 398 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Without knowing it, @andrewj, you've laid down the gaun...

By Majordennisbloodnok , 55 seconds ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 5 minutes ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 38 minutes ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 1 hour ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 2 hours ago

-

RE: Electricity price predictions

@transparent Im impressed by all your work on this. ...

By JamesPa , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 4 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 4 hours ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 4 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 5 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 20 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 22 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago