Posted by: @jamespa. A gold standard test is one that gives you the right (or in rare cases most right possible) answer.

OK so I have been giving some thought to a possible gold standard test that can be performed on a house outside a controlled environment.

It could go something like the following. It should preferably be done when the diurnal temperature variation is not too great but the OAT is well below IAT. The ideal conditions quite frequently occur on a dull period in mid winter, when its often 4C+/- 2-3C for several days and nights in a row (horrid weather in the UK - because its invariably damp). Such conditions do also occur in spring/autumn. Try to avoid doing it on days when its very cold at night and quite warm by during the day, or on days when OAT is only a few degrees different to IAT

Step 1: determine roughly the the time constant for cooling (later this will tell you the heat capacity of the fabric)

Heat the house to the target IAT, keeping it at the target for long enough that its stable and likely that the fabric is as close to equilibrium as possible (Say 2-3 days)

Turn off the heating, measure the cooling and OAT

Step 2: Prepare the house for step 3

Set up an electric resistance heating system (known efficiency of 100%).

Set up some blowers to stir up the air in the house (to minimise temperature variations)

Eliminate major sources of solar gain by obscuring south facing windows with white paper (which will reflect the light but still allow heat energy to leave the house as it would normally)

Turn off all material sources of heat other than the controlled heating and blowers. Vacate the house.

Monitor OAT and IAT and energy used

Heat the house to the desired IAT keeping it at the target for long enough that its stable and likely that the fabric is as close to equilibrium as possible (Say 2-3 days)

Step 3: determine the heat loss under reasonably controlled conditions

For at least 20 times* the time it took for the difference between IAT and OAT in step 1 to reduce by 50% (and preferably longer) monitor the energy needed to keep the IAT constant

Divide total energy used by the integral over time of the OAT - IAT temperature difference. The answer is the heat loss per degree c temperature difference inside to outside, ie the heat loss per degree C

A reasonable estimate of the uncertainty on the answer can be estimated by calculating the heat capacity of the house, which you can do by combining the results of step 1 and step 2. A proportion of this figure represents an uncertainty on the total energy needed to keep the house at constant temperature. Obviously the longer we kept the house at the constant temperature for, the smaller this will be as a proportion

(* to guarantee <5% error due to house heat capacity)

The above will give you a pretty good figure. There are still some known (and maybe some unknown) sources of error/variation on this namely:

- Variation in loss due to wind velocity

- Energy that, when occupied, goes into the house due to equipment and the occupants. This can be estimated

- Additional losses due to additional ventilation when occupied

In a passivhaus these might be quite significant, but in a passivhaus the fabric spreadsheet method is good enough. In a typical retrofit of an estate built house they are unlikely to be more than a few % so can likely be ignored for our purposes. The exception is that the wind velocity factor might be quite significant in a house that is rather exposed, particularly if its shape departs materially from a cube. In such cases it might be prudent to make some allowance

I expect some of the above could be simplified a bit, possibly with some (tolerable) loss of accuracy.

Hope that triggers some thoughts!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

How close to the true heat loss figure do we need?

Is it actual heat loss + or - 20%, ....?or more likely

heat loss - 0 to +40%

Or heat loss -0 to + 20%

Or heat loss -0 to + 10%

Or heat loss - 0 to + 3 %

Given the typical range of HP capacity is for example 5, 8, 10, 12, 16 kW (fairly large incremental steps) how close do we actually need for successful implementation of a heating system ?

Posted by: @jamespaSo with a fossil burner (or more precisely any heating where the control algorithm is linked to IAT not OAT) you can expect good correlation of energy with OAT over a sufficiently long period, but not over a short period such as a few hours.

Which is why I have tried plotting 24 hour periods rather hourly periods, and sure enough the correlation does appear to be very good, remarkably good in fact. Sure, a fossil fuel system can be expected to have a lag in response, because instead of controlling output directly from the OAT, it uses a proxy, the IAT, but, given all other things being equal, including the boiler output until it is changed, the OAT is the major determinant of the IAT, it is ultimately the OAT that determines the fossil fuel boiler output. Thus, while a heat pump responds to the current OAT directly, a fossil fuel boiler responds to the recent OAT, as it is then reflected in the IAT an interval of time later. How much this matters is not clear, but it shouldn't be too hard to find out, for example by offsetting the energy out (delivered) in hourly increments, and seeing how the correlation is affected.

Posted by: @jamespa...in your case. For your case...

Every now and then, I explicitly mention that my case is a classic n=1 case, and whilst it is not at all unreasonable to expect other buildings to behave the same way (the laws of thermodynamics aren't changed by the building they operate in), we don't know my heat loss assessment method works on other buildings until we try it. Rather than implying I am perhaps unscrupulously over-egging a n=1 case (which I am not, given my explicit statements that it is an n=1 case), it might be better to encourage others to replicate (or not) my findings. I have now boiled down (sic) the requirements to the extent that they should be available to anyone with a gas boiler:

(1) run the heating in such a way as to maintain a steady IAT. It doesn't matter how you get a steady IAT, just that you end up with one

(2) at a fixed time of day, record (a) the trailing 24 hour energy used (from the meter) and (b) trailing 24 hour mean OAT (from a cheap logging device) over a minimum period of a week

(3) adjust the energy in by your estimated boiler efficiency to get daily energy out (delivered), and then plot that against daily mean OAT

This procedure is not in the least bit onerous. Home automation enthusiasts, whatever their heat source, probably already collect this data, and could look in their records for periods when the IAT was stable (which is what I have done) and have the plots done in less than an hour. Perhaps the more curious question is why aren't people doing this? Perhaps we are in a bubble of eccentrics, the rest of the world either doesn't care a damn what their heat loss is, or if they do, they are quite happy to put up with bogus numbers because they know in their heart of hearts the numbers are just fantasy numbers made up by the marketing types to make the wheels of commerce go round.

Posted by: @jamespaIn response to the 'gold standard' question, I am not sure there is a reasonably accessible (and certainly there isn't a defined) 'gold standard'.

Gold standard doesn't need to be in quotes, it is a recognised term and concept. I fully appreciate there are many practical problems in establishing a gold standard, and applying it, but we do need something which we can agree is the right answer if we are to assess the capabilities of different methodologies. Take my house for example: the spreadsheet model gives a heat loss of ~12kW, the empirical method gives a heat loss of ~8W. Which is correct, or closer to the correct result? Perhaps both are wrong? Having a gold standard is the only way we can reliably answer those questions, but as you say, doing a gold standard test on every occasion is not practical, which is precisely why we use other more practical methods. But we do need to be aware that until we compare those more practical methods to the gold standard, we don't know for sure that our results are valid. I happen to believe an empirical method is inherently better than a model based on dubious assumptions method, and it is of some comfort that when I correct the model for the dubious assumptions, then it gives a result close to the empirical method, the comfort being that two independent methods give the order of result. But that doesn't prove they are right, it just makes it more likely they are right.

The MCS question: all I am getting at is the need for the headline performance figures used by the industry to be ones that are meaningful. Knowing that my 14kW badged heat pump can produce 14kW on a sunny spring day when it is not needed is of no practical use to me at all, in fact it is worse than meaningless, because it misleads. Knowing the same heat pump will produce ~11kW at around zero OAT (according to the manufacturers, but even this is suspect, given my empirical findings, the 11kW might be equivalent to X HP at the crankshaft in a car engine, but only a percentage of X HP actually gets to the road wheels) or alternatively deliver 8kW to the house is useful, because it tells me what it produces when it really matters. It doesn't matter how we get to using the real world figures - MCS, a campaign by MCS (ha ha very funny again), advertising standards, legislation, regulations, whatever, all that matters is we get there.

Posted by: @jamespaOK so I have been giving some thought to a possible gold standard test that can be performed on a house outside a controlled environment.

Excellent! Reviewing your method, I can certainly see what you are getting at, but I think it may turn out that it doesn't need to be that complex, which of course you say ("I expect some of the above could be simplified a bit, possibly with some (tolerable) loss of accuracy"). I am going to manually pull out some periods from my heating records when the IAT was reasonably stable (I think in practice this is becoming the sina qua non of these tests, as being in equilibrium is a much easier state to assess) and see what results I get. If they all come whithin a whisker of the same heat loss at design OAT (-2 in my case, or whatever you want for your building), then I think the method may pass muster, at least in my n=1 case.

Posted by: @iaackHow close to the true heat loss figure do we need?

My hunch (that is all it is) is +/- 5-10%. As you say, the heat pump output increments are relatively large (8kw to 10kW is a 25% increment on 8kW), but just as important is the fact that a 10kW heat pump won't in most cases put out anything like 10kW when it is really needed, at around say zero degrees OAT. We need to match the real world output at design OAT to the real world heat loss.

Edited to add 'at least in my n=1 case'... (though I hope, even expect, it can be generalised)

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @iaackHow close to the true heat loss figure do we need?

Is it actual heat loss + or - 20%, ....?or more likely

heat loss - 0 to +40%

Or heat loss -0 to + 20%

Or heat loss -0 to + 10%

Or heat loss - 0 to + 3 %

Given the typical range of HP capacity is for example 5, 8, 10, 12, 16 kW (fairly large incremental steps) how close do we actually need for successful implementation of a heating system ?

Its a very good question and one I pose above. As I say above it does depend on the actual circumstance and what design decisions may be triggered/depend on the outcome. There are several that matter which come to mind including

- Pump capacity. You are of course right they come in incremental steps but there is more than one manufacturer and the increments aren't precisely aligned.

- Linked to the above - noise level and size (which affects feasible location) and the need or not for planning consent

- Radiator sizing - again in incremental steps but sometimes the difference of 10-20% makes the difference between needing a type 33 or getting away with a type 22, which for many will matter?

- Pipe (re) sizing - does the required capacity demand internal pipe upgrades or can you get away with existing?

If you are on the cusp of any of these decisions then knowing the loss to within 30% wont be good enough to be comfortable that you are not spending money/ incurring inconvenience/ making things impossible unnecessarily, knowing the loss to within 10% probably will be good enough. I would say that 3% is more or less definitely tighter than is reasonable because heat loss itself isn't a precise number, due to factors other than temperature.

If you are not on the cusp of any of these decisions then it doesn't matter much. These percentages are based on my case (8kW retrofit, or 16KW if you believe the MCS surveyors), the design decisions that I need to make and what tolerance drives them.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaSo with a fossil burner (or more precisely any heating where the control algorithm is linked to IAT not OAT) you can expect good correlation of energy with OAT over a sufficiently long period, but not over a short period such as a few hours.

Which is why I have tried plotting 24 hour periods rather hourly periods, and sure enough the correlation does appear to be very good, remarkably good in fact. Sure, a fossil fuel system can be expected to have a lag in response, because instead of controlling output directly from the OAT, it uses a proxy, the IAT, but, given all other things being equal, including the boiler output until it is changed, the OAT is the major determinant of the IAT, it is ultimately the OAT that determines the fossil fuel boiler output. Thus, while a heat pump responds to the current OAT directly, a fossil fuel boiler responds to the recent OAT, as it is then reflected in the IAT an interval of time later. How much this matters is not clear, but it shouldn't be too hard to find out, for example by offsetting the energy out (delivered) in hourly increments, and seeing how the correlation is affected.

All agreed except possibly the last sentence. I don't think its as simple as a constant lag because the fabric isnt monolithic. However certainly I would expect applying a lag to improve correlation, albeit not give a perfect result. My best correlation (from my fossil fuel system) of 24 hour averages, is with OAT delayed by 12 hours.

Posted by: @jamespa...in your case. For your case...

Every now and then, I explicitly mention that my case is a classic n=1 case, and whilst it is not at all unreasonable to expect other buildings to behave the same way (the laws of thermodynamics aren't changed by the building they operate in), we don't know my heat loss assessment method works on other buildings until we try it. Rather than implying I am perhaps unscrupulously over-egging a n=1 case (which I am not, given my explicit statements that it is an n=1 case), it might be better to encourage others to replicate (or not) my findings. I have now boiled down (sic) the requirements to the extent that they should be available to anyone with a gas boiler:

I didn't mean to imply you were doing anything unscrupulous, am sorry you took it this way and apologise if anything I said implied that.

All I am trying to say out is that there are some distinct features of your system (in the context of our discussion) which we can think about. Given that, as you say, we know the laws of thermodynamics, we can work out more or less the consequences of these features and how these might be different in other systems, in particular those with a fossil burner which are the systems of greatest interest.

Posted by: @cathoderayI have now boiled down (sic) the requirements to the extent that they should be available to anyone with a gas boiler:

(1) run the heating in such a way as to maintain a steady IAT. It doesn't matter how you get a steady IAT, just that you end up with one

(2) at a fixed time of day, record (a) the trailing 24 hour energy used (from the meter) and (b) trailing 24 hour mean OAT (from a cheap logging device) over a minimum period of a week

(3) adjust the energy in by your estimated boiler efficiency to get daily energy out (delivered), and then plot that against daily mean OAT

Agreed except I would substitute (based on my own measurements done more or less this way) a minimum of 3 weeks instead of one week. One week wont be enough in many cases (including, for example, mine) to eliminate the effects of the heat capacity of the house to a sufficient extent, unless the OAT is both quite low and pretty stable in which case doing what you say but ignoring the first couple of days may well be good enough.

Put another way the house is not in equilibrium when the IAT alone is stable, it is only in equilibrium when both the IAT and OAT are stable. Since this is not entirely under our control we need to adjust our measurement so that the error caused by the lack of equilibrium is acceptable.

I agree that this can be done by pretty much anyone, which is why I believe that advocating using experimental methods to supplement (or substitute for) the fabric spreadsheet method is a worthwhile endeavour.

Once that is determined a pump selection should (as you say) be made on actual capacity at the design flow temperature not sticker capacity which is essentially meaningless other than for manufacturers (eg Samsung, Mitsubishi) that clamp the output capacity in the firmware so that it is artificially constant over a range of OATs and FTs.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaknowing the loss to within 10% probably will be good enough.

Are you saying then + or - 10%

or + or - 5%

I note that the tolerance for ashp ratings (EN14511) are:

Tested cooling and heating capacity ≥ 0,88 X declared

Tested EER ≥ 0,85 X declared EER

Tested COP ≥ 0,85 X declared COP

Posted by: @iaackPosted by: @jamespaknowing the loss to within 10% probably will be good enough.

Are you saying then + or - 10%

or + or - 5%

I note that the tolerance for ashp ratings (EN14511) are:

Tested cooling and heating capacity ≥ 0,88 X declared

Tested EER ≥ 0,85 X declared EER

Tested COP ≥ 0,85 X declared COP

A bit of a moot point as this is now into hand waving territory, but I had in mind +/-10%.

Thinking at the next level of detail, if I had a determined requirement where it was reasonably certain (a) that the actual loss did not exceed this number by 5%, and (b) that the actual loss was not less than the number by more than 10%, I think that would be good enough in my 8kW retrofit example. However as I say there are circumstances where a significantly larger uncertainty is tolerable because it would not affect a critical design choice, and probably some circumstances where something tighter would be helpful.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

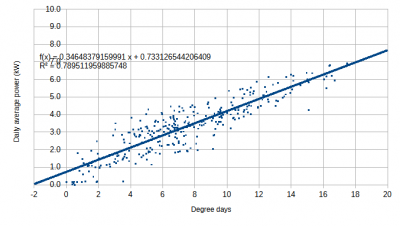

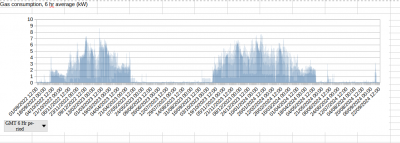

So we can look at the scatter on some more experimental data, here is a plot for my gas fired system. It shows average daily power (ie daily gas consumed divided by 24hrs) vs degree days, using data from the entirety of the 2022-23 and 2023-24 heating seasons. In my (n=1) system the IAT is controlled, there is no weather compensation, so both some scatter and a lag is expected.

The plot actually attempts to deal with the lag, the 'degree day' axis is actually (0.6*the number of degree days for the previous day + 0.4 x the number of degree days for the current day). 0.6/0.4 (=1-0.6) is the figure that gives the best correlation.

I use degree days because its what I can download for free. I could probably alternatively have used average daily temperature, but as @cathoderay points out this would simply have changed the intercept. Hourly temperature is not available for free. I use total gas consumption again because I can get it. Its a pretty good proxy for heat to the house but not perfect. The house is maintained at close to 20C most of the time, and doesn't deviate from this by more than a couple of C for any material time except when I am away ('away' data is included as I cant be bothered to exclude it).

This level of information is available to anyone who can get their smart meter readings.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa - an interesting chart, it shows the method working for a large fossil fuel data set. I suspect if you cleaned up the data a bit, you might get better correlation, but the line's slope and intercept will very likely stay pretty much the same. I note you have energy in, not energy out, on the Y axis. Depending on the baseline you used for your HDDs (16 degrees?), and your boiler efficiency (let's say 95%, because I presume you run a tight ship), I conclude your measured heat loss is around 7.6kW x 95% = 7.22kW at -4 degrees OAT. That gives you your heat pump requirement, one that will put out at least 7.22kW, lets say 8kW with a small margin for error.

Posted by: @jamespaI use degree days because its what I can download for free. I could probably alternatively have used average daily temperature, but as @cathoderay points out this would simply have changed the intercept. Hourly temperature is not available for free.

Using mean OATs means you don't have to convert back from HDDs (not an easily grasped concept for everyone) to OATs (universally understood). You can in fact get hourly temperature obs from the Met Office WOW website (free registration required, if you are paranoid, use a temporary email address) which has a huge number of weather observation stations, some amateur, but none the worse for that. My nearest WOW website is about five miles away, but not ideal, as the geography is rather different. In due course (usually about 9 months after the end of the calender year) the Met office also publish annual data sets for various locations on their MIDAS open website (click on the MIDAS Open button in the middle of the page), but these are more spread out. But recording your own OAT is not difficult, and not expensive, and it produces data that is interesting in its own right, as well as having other uses.

One more small point: I think plotting daily kWh converted back to average kW and then calling that a daily average power when in fact it is an any time unit average power might be confusing. My charts use the perhaps slightly more graspable total daily kWh hours, where the line is at the say -2 mean OAT tells me what the daily use will be at that daily mean OAT, ~192kWh in my charts. I can then convert back to hourly use, 8kWh, which in turns tells me I need a 8kW unit to deliver 8kWh in one hour. Now, having written that, my approach also seems confusing! But whatever method is used, I think graspability is important, people need to be able to understand what they are looking at at a glance.

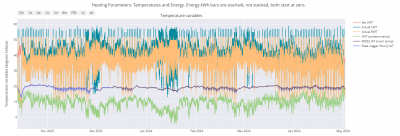

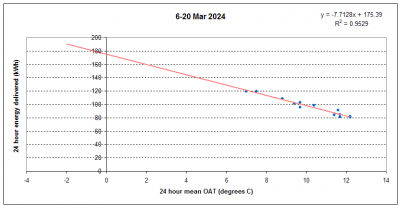

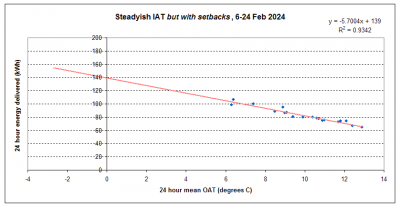

Meanwhile I have been looking at my own OAT based plots for my n=1 building. Looking at the temperature variables for the last heating season, I can see various periods during which the IAT was reasonably constant:

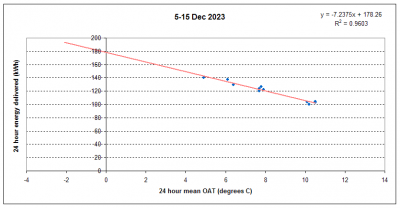

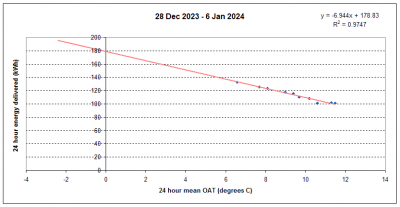

I can then plot 24 hour energy delivered against 24 hour mean OAT for these periods:

and they are all pretty much the same (as I would expect), and give the expected 192/24 = 8kW result at -2 OAT. However, if I look at a night time setback period, visible in the first plot as periods when the IAT has a marked saw tooth pattern, as well as by other markers, ie the IAT is not stable, and the mean is lower, and all sorts of other factors come into play, then, as expected, I get a very different plot:

which underlines the importance of doing the assessment with a steady IAT.

I do think we are onto something concrete and useful here, but we are still only at n=2. Please please please could others post their data/charts! We need to replicate (or refute) the findings!

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderay@jamespa - an interesting chart, it shows the method working for a large fossil fuel data set. I suspect if you cleaned up the data a bit, you might get better correlation, but the line's slope and intercept will very likely stay pretty much the same. I note you have energy in, not energy out, on the Y axis. Depending on the baseline you used for your HDDs (16 degrees?), and your boiler efficiency (let's say 95%, because I presume you run a tight ship), I conclude your measured heat loss is around 7.6kW x 95% = 7.22kW at -4 degrees OAT. That gives you your heat pump requirement, one that will put out at least 7.22kW, lets say 8kW with a small margin for error.

Yup pretty much. My boiler does actually condense so its just possible that the efficiency exceeds 100%.

Hence choosing the 7kW Vaillant which does 8.6 at -2 , looks nice, is quiet and fits in the available space. More expensive than the cheapest but not punishingly so. 8kW Samsung a bit marginal (because it is 8kW), various others discounted because of the terms of my planning approval or because their tech support is unresponsive (which is true also of Samsung).

Furthermore:

- at 8kW 2*22mm primaries (upstairs/downstairs) are fine even if they are not balanced so no need to upgrade pipework

- and it fits under a window and, in the right circumstances, there is a choice of units which would meet the conditions for permitted development.

all unlike the 16kW which the paid-for surveyors determined was required.

Posted by: @cathoderayYou can in fact get hourly temperature obs from the Met Office WOW website (free registration required, if you are paranoid, use a temporary email address)

I think I tried that once and it didnt work for some reason, but thanks & I will try again.

Posted by: @cathoderayOne more small point: I think plotting daily kWh converted back to average kW and then calling that a daily average power when in fact it is an any time unit average power might be confusing.

I agree in principle but I have several other charts of 3 hourly, 6 hourly, 12 hourly average power plotted against day (example below) so I can check in case peaks are a problem and I wanted the same axes on all for the benefit of a heating engineer who needs to be sufficiently convinced by the data that he will massage the fabric spreadsheet accordingly and in a way that gives him sufficient confidence that he can satisfy his MCS masters if audited.

I note your figures and plots and that they all point to the same conclusion. It would be interesting to run your house without weather compensation (or with WC set several degrees higher) and controlled by a room thermostat, and equally mine on weather compensation, so we could get an experimental comparison of the two under similar conditions. For the reasons I set out above I would expect the thermostat controlled scatter diagram to be much less well correlated (and mine is relative to yours, but its a different house and a slightly different experiment), thus requiring more data to eliminate the random variations due to history.

Posted by: @cathoderayI do think we are onto something concrete and useful here, but we are still only at n=2. Please please please could others post their data/charts! We need to replicate (or refute) the findings!

I agree. For me experimental measurements are the way to do it to for a retrofit, with the fabric spreadsheet used to sense check the experimental measurements and to apportion the loss between rooms for rad sizing. However I don't think anybody with a voice in the industry agrees, so what I think doesn't matter. I suspect that reluctance to rely on the customer, which is understandable, plays a very big part in this.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa - your heat pump selection logic makes sense, and I also get the importance of aesthetics. This thread now demonstrates a fossil fuel boiler being used to determine the size of a heat pump, with full instructions on how to do it. We need to add the usual caveat, do this at your own risk, and do sanity checks, including as a minimum a spreadsheet based heat loss assessment, even if in places the thrust of this thread is that such heat losses may not be accurate. My hunch is that anyone who is going to use an empirical method will already have a suitably sceptical (pleasantly sceptical that is) mindset.

Posted by: @jamespaI think I tried that once and it didnt work for some reason, but thanks & I will try again.

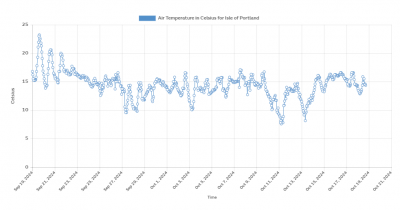

Here is the hourly air temp at Portland Bill for the last month. Go to the home page, search for a location, go to the full data and select the graph tab, and then set the parameters for what you want. With a bit of jiggery pokery you can get the data the chart is plotted from, or alternatively login (free registration) and download the data in spread sheet form. It is limited to 31 days per download, but that is not the end of the world, just a bit tedious having to do multiple downloads. If you want data from further back, the MIDAS site will let you download huge datasets.

Posted by: @jamespaIt would be interesting to run your house without weather compensation (or with WC set several degrees higher) and controlled by a room thermostat, and equally mine on weather compensation, so we could get an experimental comparison of the two under similar conditions.

Agreed, but running a gas boiler on WC is the really interesting one, if it can be done, because it gets closest to the heating provided by a typical heat pump. From what I've read it can't be done with a standard installation, at least in this country, but maybe for a short period something approximating it could be done manually. Very tedious, but it might answer the question of whether the heating regime (timer plus room stat or WC) makes a difference. My hunch is it doesn't, at least not to the point it matters, as long as you maintain equilibrium, and use a long enough plotting interval, because the laws of thermodynamics don't care where the heat came from or how it got there, just that it is there.

Posted by: @jamespaHowever I don't think anybody with a voice in the industry agrees, so what I think doesn't matter. I suspect that reluctance to rely on the customer, which is understandable, plays a very big part in this.

I wouldn't be surprised if some do agree, but they don't want to put their head above the parapet. It's what the negative side of regulation does, it stifles innovation. We, on the other hand, can, and have done so here, and at least some people do read this forum. I do appreciate the reluctance to rely on the customer, but frankly the necessary data, if the customer has it, is pretty straight forward, and unlikely to be corrupted, either intentionally or unintentionally.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderayAgreed, but running a gas boiler on WC is the really interesting one, if it can be done, because it gets closest to the heating provided by a typical heat pump. From what I've read it can't be done with a standard installation, at least in this country, but maybe for a short period something approximating it could be done manually.

Many gas boilers do or can support WC.

However the way we do dhw means that you may have to jump hoops to implement it. A friend of mine has employed the well known trick of switching a resistor in and out of the external temperature sensor connection to fool his boiler (set up with WC) that the OAT is really cold during the period he is heating hot water.

I agree with you that it's irrelevant to the loss assessment however. The laws of thermodynamics are sufficiently robust that we don't need to run the experiment to prove this.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

-

Gen 6 Samsung ASHP losing 20C of DHW in 60 min directly after generation

1 month ago

-

Should I make my radiators smaller?

11 months ago

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 310 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 23 seconds ago

-

RE: Electricity price predictions

i only know about Intelligent Octopus Go ToU, where acc...

By SKD , 41 minutes ago

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 1 hour ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 2 hours ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 2 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 3 hours ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 5 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 6 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 7 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 21 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 23 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago