Anyone able to provide some feedback before I make my finale decision? Samsung vs Baxi vs Vaillant

Posted by: @heatgeekThe Vaillant apparently has an uncontrolled (not PWM) fixed speed pump, therefore operates along a standard constant speed curve.

I have a 7kW Vaillant and it definitely has a PWM pump. The 12kW may differ of course. This water pump can, if you wish, be turned up or down manually from the UI so is under the control of the heat pump controller. So far as I can tell from the very limited monitoring I have done of pump speed (I can only tell by eyeballing the controller) Vaillant have however made the design decision not to vary it automatically with compressor output. I have only recently started to look at this aspect of its behaviour and don't have 'real time' monitoring so cannot be certain whether or not it does in some circumstances change the pump speed. Someone with more comprehensive monitoring such as that provided by openenergymonitor may know more and may even have worked out the control algorithm!

Posted by: @heatgeekOn another interesting aspect, it was suggested at some time that the max. power of a HP could be reduced by implementing silence mode. I looked at the official Vaillant technical data regarding this and the results are surprising. At -7C/35W, the 3.5kW, 5kW and 7kW units still deliver full output. However, at the different noise reduction settings, the 3.5kW reduces power proportionally and the COP actually improves! The higher power units, however, actually collapse totally on power output. Therefore, the moral of the story is do not use silence mode on a Vaillant? Amazing. It would be interesting to know why.

There are those who say never use NR mode on any heat pump when its being used for heating. Their argument is that, by limiting the compressor modulation (which is the principal effect of NR/Silence mode), it reduces the maximum output. This is of course true although, depending on how hard the compressor is 'pushed' in normal operation by the machine, the limitation could be large or small. The same people then go onto argue that NR mode is intended for cooling where you typically don't require as much output at night, which is also when noise matters most. That's also in principle true at least in many cases.

For me its a case of 'horses for courses'. If you can tolerate a reduction in max output, which in many cases you can, and want a noise reduction, then why not use it? My heat pump is roughly 'right sized'. I use NR at night only, to suppress the extra noise which occurs during defrost. This does impact output and, when its -5 outside, the house cools by about a degree in the 8 hours that NR mode is 'on'. But hey, many people do a night-time setback deliberately to achieve the latter! Possibly Im paying a bit extra as a result, or possibly not, but its good to be nice to the neighbours. Other than during defrost the heat pump is whisper quiet, so this guarantees they cant ever hear it.

There are some people on openenergymonitor that suggest activating NR mode when DHW is being heated, because it increases the heat up time but improves efficiency. Thats logical. The Vaillant machine already offers a choice of 'level of aggression' in its DHW modes, apparently invoking NR provides a mid-way between the Vaillant eco mode and the Vaillant normal mode. Similar presumably applies to other manufacturers, depending on how much control they give you over DHW 'aggression'

As to whether the 'minimum' output can be reduced by invoking NR mode, I am personally sceptical that that is the case (because if so why would they not design this in to increase the modulation range), but Im happy to be proved wrong because designers dont always do the obvious things!

That said, one mechanism I can see which is definitely plausible, and by which nr might reduce min output, occurs if the heat pump normally ramps up its compressor to max when it first switches on, and then cuts back as the target FT is approached. Mine certainly does that at least some of the time; I have seen evidence that Mitsi heat pumps do too and I would not be surprised if many heat pumps display this behaviour. If NR stops the compressor ramping up to max at the start of a cycle then, aggregated over a cycle, the average power will reduce. There is another thread where this might actually get put to the test.

The 3.5kW Vaillant is, I believe, a software-limited 5kW unit. Similarly the 10kW is (I believe) a software limited 12kW. Quite a few manufacturers do this, I presume so they can sell at differential prices and/or publish lower noise figures. This will affect how NR mode and modulation ration behave! The practice of software limiting capacity has been around for decades, ICL used to do it on their computers back in the 1980s.

Posted by: @heatgeekWhat is this "energy integral" that you talk about?

Its the Vaillant term for the aggregated departure of the actual flow temperature from the target flow temperature, measured in degree minutes. They declare its use in at least one control loop, but it may well be used more extensively (I don't know and dont even know it its known). PID (proportional-integral-differential) control is a well established control mechanism in many fields, and the strength of each component is tuned to make the control loop work optimally. I don't know if the flow temp control loop uses P, P-I or even P-I-D, but given that the energy integral is measured I imagine it may well be P-I.

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @jamespaI have a 7kW Vaillant and it definitely has a PWM pump.

I was previously under the impression that the Vaillant had a Grundfos UPM2 pump which is an externally cable controlled OEM version but was puzzled by why people say it only has fixed speed operation. Brendon Uys made the statement that the Vaillant pump speeds up to maintain flow when valves are turned off and he has no idea why, which I took to be not so complimentary. Hence my interest in getting hands-on description from @declan90 of what is really going on as he has monitoring equipment and seems to be across the pump issue. There is a lot of contradictory information about.

Regarding silence mode, as you are using it successfully on a 7kW unit, I take it that the technical data published by Vaillant is erroneous. It does on the face of it seem implausible.

Private individual. No affiliation with commercial "Heat Geeks" of same coincidental name.

Posted by: @heatgeekPosted by: @jamespaI have a 7kW Vaillant and it definitely has a PWM pump.

Regarding silence mode, as you are using it successfully on a 7kW unit, I take it that the technical data published by Vaillant is erroneous. It does on the face of it seem implausible.

The output is not, so far as I can tell, limited to 3.8kW when NR is active although I have only limited monitoring capability so could just be wrong.

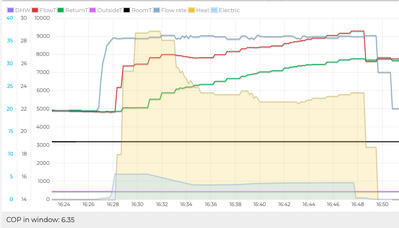

I cant be sure exactly what the limit is because I don't have a direct monitor of instantaneous heat output, only an hourly measure of total so far that day (reported by Vaillant). Looking back over a few weeks, I can certainly see 6kW output during the operation of noise reduction , that's at OAT <0 and 40C FT or thereabouts, compressor limited to 50% (60% is the default but you can change it from 70%-40% in the installer menu). The main effect seems to be to slow down recovery from defrost quite significantly, to the extent that the peak FT slowly reduces (below the target) over the period that NR is active.

My experience of my 7kW Vaillant is that the compressor cruises along at 40-50% even when its - temperatures outside, and only for short periods invokes 100%. My heat pump is only slightly oversized (perhaps 1kW, although that's another number I have yet to determine exactly) I was expecting it to 'cruise' at a higher level in cold weather, but it looks like Vaillant have designed it so that there is extra oomph for initial heat up and when doing the legionella cycle.

I'm also interested in a description of whats going on with the water pump. Brendon said at one point that it adjusts to a more or less fixed speed based on the model capacity, and I have a feeling that may be right, judging by the few observations I have made. I know my installer had it running, during initial testing when he was forcing it to do various things, at double the rate that I have observed during actual operation. I could spend a few hours watching the controller, but have better things to do!

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Further to the above here is the system pressure measured by my Vaillant. I know that this reacts to pump head, because (a) its about 0.6bar less than the pressure measured at the filling loop and (b) it rose by about 0.6bar today when the water pump switched off due to OAT being above the max I have set for heating.

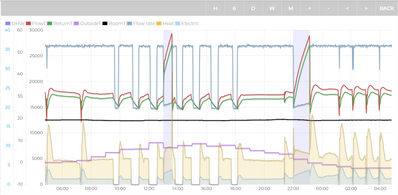

There is a steady drop over the period due to the system losing pressure (obviously a slow leak somewhere) and some spikes which I think correspond to when its heating DHW, but the pump head appears to be essentially constant. Since I don't have valves opening and closing this implies a fixed flow rate, suggesting that Brendons statement that it adjusts to a more or less fixed speed based on the model capacity is correct. This doesnt however tell us whether it maintains a fixed head or fixed flow because, in my system, the two would be the same.

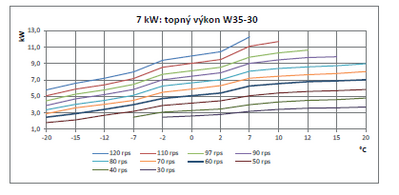

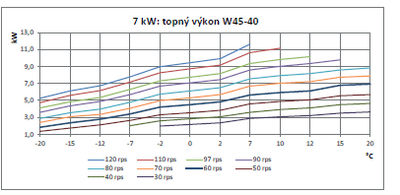

During this period the output heating power varied over the full range that the system is capable of according to the data sheets available from the Czech Vaillant site

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

I'm unsure as to the exact pump in the outdoor unit, but under the impression it is PWM. Flow speed can be adjusted on the panel by residual pump head and/or a % speed for any given mode (heating/DHW/cooling) - I've tweaked the % on DHW to see what impact it has on dt (but can't be certain on COP due to 'air' issue).

I've bookmarked the OEM discussion on flow rate vs efficiency @jamespa shared, certainly an interesting read. I can't help but think that the engineers must have had reason to effectively fix flow rate at that required for dt5 at maximum badged load. Presumably they felt little benefit in modulating it. I know from the Heat Pumps UK facebook group that there are a number of installers (that seem very knowledgable to me) that insist best practice is to reduce the residual head to achieve the required flow rate that would achieve dt5 at design OAT and design/measured heat loss. Can see the point made about lowering the average flow temperature however most of the time my unit exceeds what it is aiming for, so will be interested to see the impacts when I do get round to testing.

When in heating mode my pump runs at max output (36 L/min) (did drop before xmas due to filter becoming gunked up), this drops to about 20 L/min between cycles. Only have TRVs in a few places and all set to max, so haven't noticed anything on valve closures etc.

Energy Stats does a good write up on the energy integral https://energy-stats.uk/vaillant-arotherm-firmware-351-06-07-problems-energy-integral/ in relation to an observed issue with an older firmware (note highlighted limitations as firmware updates only possible with board replacement!).

As per the attached the observed behaviour is an initial ramp up (to target flow temp) and then compressor is backed off, potentially to minimum if steady state cannot be achieved. As flow temps exceed target then the integral ticks up and will eventually turn the compressor off. Obviously this occurs far quicker at higher OAT.

I haven't yet experimented with what would happen in NR mode wrt to initial ramp up and the effect (if any) on COP. My main worry about setting this permanently would be if the unit struggled to get up to the required flow temperature, e.g. after a defrost.

@declan90 I have some hopefully interesting input for you if you don’t think it is bollocks. Your statement about adjusting your pump for 5C dT got me going. In the absence of other input, I decided to go back and look at the data I had previously accumulated. I made a snapshot of your system on a specific day and another snapshot of one of the top-performing Vaillant systems (Airstead, Surrey) for the same day.

Firstly, from my original data, I think that I am perfectly correct in my assessment of the Vaillant operation. The flow rate is fixed and, when it cycles, the flow rate is a square pulse diagram, either on or off. When OAT increases, the dT decreases because of the fixed flow to modulate the heat flow to the emitters. This results in a large number of the systems on heatpumpmonitor running at 2-3C dT which is bad in my view. In your case, the dT shown is extremely low at 2C. Your on/off flow rate is 36 l/min which matches a 12kW output. The system starts cycling at 4.5C which is very low and confirms your statement about over-sizing. As a pure aside, your lowest OAT is -2.5C when others are at 1 to 2.5C. Are you in the Orkneys? Presumably, however, this is just reporting and doesn’t affect your WC operation.

Looking at the Surrey system with a 12kW system also, their result is totally different with very little cycling and wider dT of 4C at 1.5C OAT when high heat output is required. This apparent disparity puzzled me until the penny finally dropped. They have matched the maximum output of the HP to the maximum heat load of the house. WTF?? Clever sods. The flow rate has been set to <30 l/min when the normal 12kW maximum would have been 36 l/min, like yours. This corresponds to 10kW max. @ 5C dT which must be the peak heat load of the house and the dT then reduces from there.

For me, this puts the Vaillant in a different perspective for which I must eat humble pie. The fixed peak flow rate at label output together with a PWM pump never made any sense to me, coupled with the modulation in dT. The intent of the designers must have been to allow adjustment of the fixed flow rate and the HP will then modulate output to provide the corresponding max. heat output @ 5C dT (with setting of rads). In fact, if the HP will allow it, you could adjust rads for >5C dT and lower flow further to provide desired output. The HP should modulate output accordingly.

Low dTs deteriorate COP. Let me explain my viewpoint. The COP of a HP is determined by two main parameters:

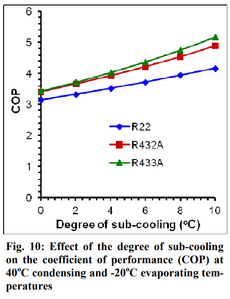

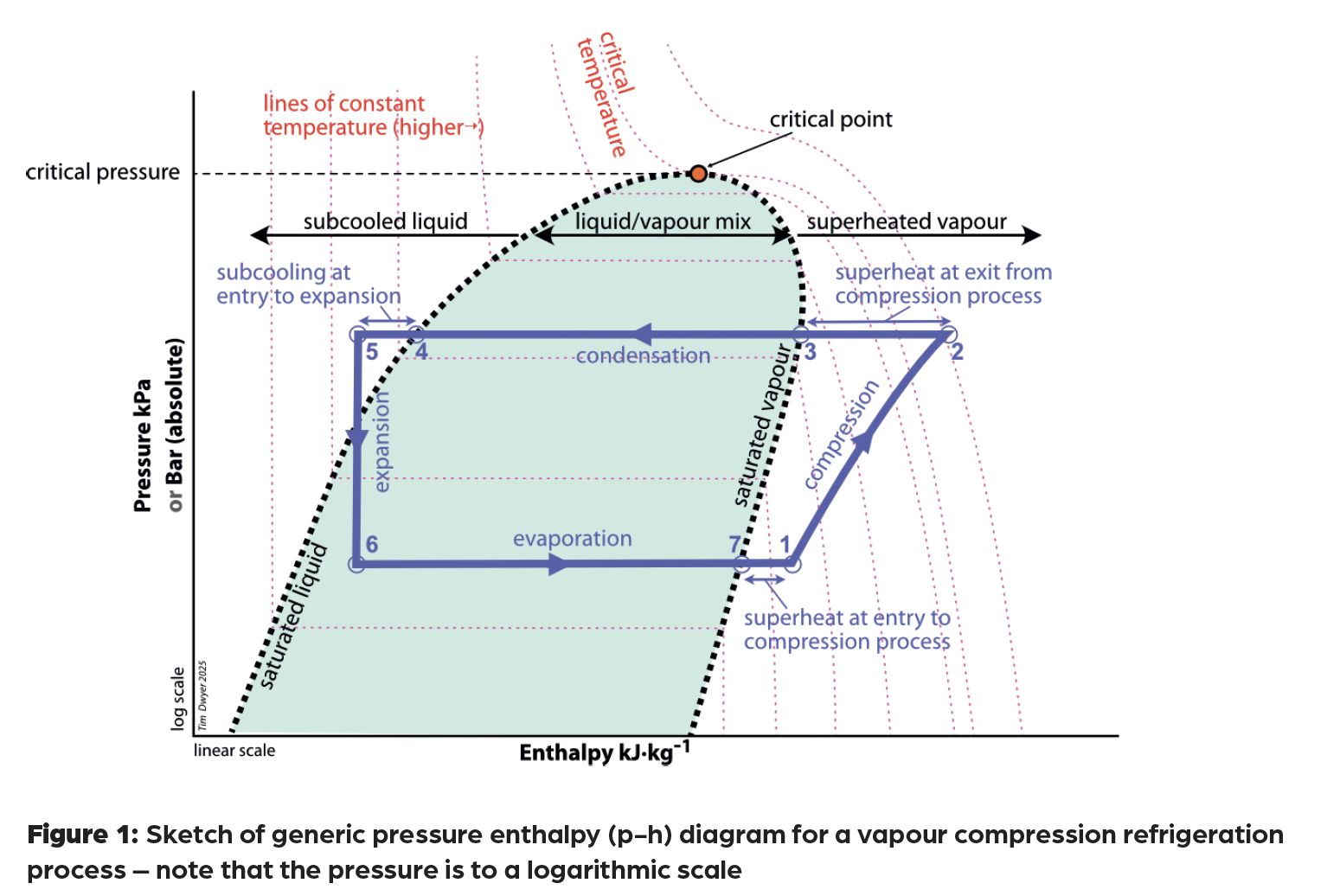

1. The mean temperature of condensation in the PHE (Plate Heat Exchanger) coupled with subcooling temperature. Subcooling is the difference in temperature at input of EEV (Electronic Expansion Valve) between the temperature of the condensate and the saturation temperature of the condensate.

2. The temperature of the air source at the evaporator (superheating at compressor input).

The former is relevant here. A high dT across the PHE lowers the mean condensate temperature and ensures better subcooling which improves COP. See diagram.

This is the reason, IMHO, that @heacol states that 8C dT is optimal which results in lowest mean condensation temperature. Very low dT at the PHE runs the risk of sub-optimal condensation with gas remaining in the liquid and getting into the evaporator. This is the reason that HPs will turn off at too low dT. Therefore high dT by definition means better COP.

As you say that you are over-sized, you can do likewise and try and turn your flow down to 21 l/min corresponding to max. 7kW with 5C dT. The lowest modulation output, however, will probably be unaffected. If I am right, this is a pretty clever facility and explains IMHO why Vaillant, counterintuitively, have fixed flow with a PWM pump.

Private individual. No affiliation with commercial "Heat Geeks" of same coincidental name.

Posted by: @heatgeekTherefore high dT by definition means better COP.

I think you may be considering only one half of the equation here, and the question is how they balance (I dont know)

High DT may mean higher COP at the heat pump for any given flow temperature but if the DT is higher (than some initial starting point) the flow temperature has to be higher to get the required output from the emitters, because the emitter output is dependent on the average difference between emitter temperature and room temperature.

So for example if DT is 5 and the emitter output is sufficient at a FT of 32.5, the FT will have to be increased to 35 if the DT goes up to 10 (presuming that the objective is to achieve the same room temperature).

How does it affect the argument when you consider the whole system not just the heat pump?

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@heatgeek an interesting eureka moment - would provide what certainly sounds like a plausible explanation for the pump arrangement.

I will likely bring up the flow rate / dt with my installer on first service (due around May). A little hesitant to play too much without understanding what the heat pump would do if it decided the dt got too wide (if I only make adjustments within reason is decreased COP the worst case rather than waking to a cold house - which I'm not sure would go down well with a young family!)

Other angle is does reduced flow rate impact on any balancing of the rads?

I need to back calculate the required residual head setting (I know Paul Spence has put the equation on Facebook). Might also be a tad cautious and calculate heat loss at -5C as we did see -4C a few times this winter! Ha, far from the Orkneys - just a hilly village in the Midlands ... Washing drys nice in the wind in summer.

Hoping the DHW 'air' issue resolved itself (for ease of comparing COP outcomes of nothing more).

Also hoping to experiment next winter (after redoing the loft insulation) as to flow temperature required in a section of the house with UFH and rads (isolating the rads) as currently UFH on its own WC settings running very low. Would be nice to know if the VDM mixing station could go in the future (if aligned to main house rads), works ok for me now as we've got play mats etc over sections of the floor for the kids.

So I imagine I'm best to test the above first?

Would be nice if expanding the dt did increase the OAT at which cycling occurs but likewise suspect there won't be a noticable difference. I did try changing the threshold on the energy integral to try and force longer run times (which it did) but reverted as was unsure it actually improved COP (did increase temperature fluctuation)

Posted by: @heatgeekLow dTs deteriorate COP. Let me explain my viewpoint. The COP of a HP is determined by two main parameters:

1. The mean temperature of condensation in the PHE (Plate Heat Exchanger) coupled with subcooling temperature. Subcooling is the difference in temperature at input of EEV (Electronic Expansion Valve) between the temperature of the condensate and the saturation temperature of the condensate.

2. The temperature of the air source at the evaporator (superheating at compressor input).

The former is relevant here. A high dT across the PHE lowers the mean condensate temperature and ensures better subcooling which improves COP. See diagram.

So I have been thinking about this and trying to rationalise it with three other things namely

(a) the Carnot equation which means that COP reduces as either (a) OAT reduces or (b) Flow temperature (FT) increases

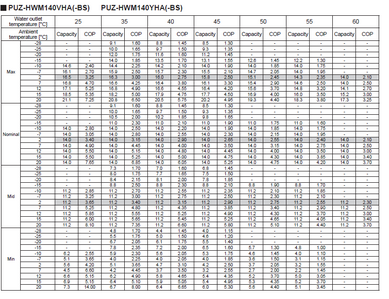

(b) the fact that manufacturers performance tables (example below) clearly illustrate the effect of (1), specifically that COP reduces as FT increases

(c) the heat pump is only one part of the system which also includes the other components and most particularly (for the purpose of this discussion) the emitters

My first observation is that emitter output varies with the difference between average emitter temperature and room temperature, and average emitter temperature is FT-dT/2. So if dT is increased by some means it is necessary to increase FT by half as much to maintain the same emitter output and thus house temperature. This would, according to (a) and (b) reduce COP not increase it.

Note that this doesn't negate the point in (1) above (which is not disputed), however it is a consequence of the fact that the heat pump is part of a system which has a purpose (namely to keep the house at a specific temperature) and adjusting a one heat pump parameter may necessitate adjusting other system parameters in order that the purpose is still achieved.

So the next question is, does this system consequence exactly offset the effect in (1), does it dominate the effect in (1) or does the effect in (1) dominate this system consequence.

To first order the answer may be that it exactly offsets the effect in (1). The argument is as follows:

The statement made above is that "the COP of a HP is determined by ... The mean temperature of condensation in the PHE (Plate Heat Exchanger) coupled with subcooling temperature.

The 'mean temperature of condensation in the PHE (Plate Heat Exchanger) coupled with subcooling temperature' is, in simple terms, the temperature of the fluid on the refrigerant side of the PHE. Obviously the temperature of the fluid on the refrigerant side must be no less than (actually very slightly larger than) the temperature on the water side of the PHE, otherwise the heat transfer goes the wrong way. The input water temperature to the PHE is the return temperature and the output temperature is the flow temperature. If the PHE is both perfect and infinite in size, the temperature profiles on water and refrigerant side will exactly match and the means will therefore be equal. In this case the system consequence of increasing deltaT precisely offsets the effect in (1) above and the COP is the same for any given average emitter FT.

If this analysis is correct then previous statements made both by @heatgeek and I are wrong because the upshot is that changing deltaT may neither increase nor decrease the COP.

There will very likely be second order effects buried either in the engineering eg of the PHE, the control loop which determines the compressor frequency or in the contributions of the respective proportions of the refrigerant cycle (illustrated in the link below). For example if the heat pump control loop, knowing that it needs an FT of say 30, ramps the compressor to produce hot gas at 35 without taking into account the characteristics of the fluids as they pass through the PHE, then the effect in (i) will dominate. However I don't know if that's what happens.

My principal take aways from this are

- to withdraw my assertion that increasing DT across emitters necessarily reduces COP

- to conclude that the contention by @heatgeek that increasing DT necessarily increases COP is equally suspect

Secondary take-aways are:

- I stick to the argument that increasing DT does require an increase in FT (assuming that the system requirement is to maintain house temperature). This, from ALL manufacturer data, appears to reduce COP, however since such data in presumably at fixed DT it is not the data we need for this particular piece of analysis

- Brendon has never explained the argument for his position and in the absence of an explanation we cannot verify it

- we still dont know why we conventionally design for a DT of 5, or even whether it is the right thing to do

- we cant be sure whether increasing DT (whilst maintaining house temperature) increases COP, reduces COP or makes no difference.

one step forward, two steps back?

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

@jamespa One can only consider the whole system. The DT is a consequence of the emitters connected to the HP. I agree that COP is determined not only by DT across the PHE but the flow temperature also. If a manufacturer implemented an algorithm to initially boost flow temperature at startup to accelerate room temperature, this will obviously impact COP negatively. The HP can only react to what it is connected to with resultant COP.

In terms of the flow behaviour that we are discussing, one can make an analogy in electronic terms. The Samsung and Daikin DT management can be viewed as a constant voltage (DT) generator. Adjustment of the resistance (lockshield valve) will vary the current with constant voltage to set the power. With Vaillant, it is a constant current generator and adjustment of resistance varies the voltage (DT) to set the power. In the latter case you can adjust the current to set a particular voltage (DT e.g. 5C) which can then “modulate” from 5C to 2C. Hence @heacol comment that he doesn't understand why the pump maintains flow when valves are turned off. The same is not true of the other method where the DT is fixed and modulation is dependent on the compressor range. Therefore, on the face of it, the Vaillant has a much larger range of power adjustment plus consequent modulation? Is this a method of dealing with an over-sized Vaillant if they can always work down to 2C DT, e.g. Surrey case? I don’t have a Vaillant so can’t validate this theory. That’s my take, anyway.

Private individual. No affiliation with commercial "Heat Geeks" of same coincidental name.

Posted by: @heatgeekIs this a method of dealing with an over-sized Vaillant if they can always work down to 2C DT, e.g. Surrey case? I don’t have a Vaillant so can’t validate this theory. That’s my take, anyway.

I honestly dont know. Mitsubishi seem to have a fairly similar modulation ratio, but those pumps are, I think, also constant flow (like Vaillant the water pumps themselves are PWM, but like Vaiillant I dont think that is used). I have looked at some other manufacturers briefly, and an output modulation ratio in the range 2.5:1 to 3:1 seems very common. Unfortunately I haven't found the specs for Samsung which we know implements constant Dt not constant flow. Ive found the max output figures of course but not the min, so cant compare.

Samsung historically implemented 'hot gas bypass' which, as I understand it, is a way to 'ditch' energy available from the compressor when its not wanted. This has the potential 'artificially' to extend modulation range but with the limitation that you are 'throwing away' energy that you have put into the compressor. I dont know if other manufacturers do this, nor whether it has any meaningful effect on COP.

I think the bottom line is that, until we can find specs for the minimum output of Samsung heat pumps (and COP at the minimum output), we dont know whether the Samsung design philosophy is superior, inferior, or about the same (as regards this aspect of behaviour).

4kW peak of solar PV since 2011; EV and a 1930s house which has been partially renovated to improve its efficiency. 7kW Vaillant heat pump.

Posted by: @declan90Other angle is does reduced flow rate impact on any balancing of the rads?

Answer is, yes. Power set for a rad is the Flow x DT x SH-of-Water. So if you adjust the flow down, you will have to adjust DT upwards to achieve the same power output. This is what I believe Surrey has done to get a larger DT to start from, as DT "modulates" downwards. Reducing the fixed flow setting then obviously sets the maximum power out from the HP.

Private individual. No affiliation with commercial "Heat Geeks" of same coincidental name.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 222 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

@transparent Triggered by the various commen...

By JamesPa , 10 minutes ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 40 minutes ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 46 minutes ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 1 hour ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

I've found that generally the humidity in the house is ...

By IRMartini , 1 hour ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson — as @tasos suggests, plotting multiple variabl...

By cathodeRay , 5 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 6 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 17 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 19 hours ago

-

RE: Setback savings - fact or fiction?

I also need to correct something I said by mistake earl...

By cathodeRay , 19 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 22 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 22 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 22 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 24 hours ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago