Controversial opinions - pure weather compensation, buffer tank, heat loss, oversized heat pumps

@uk_pete_2000 Adding the GW04 mainly makes it easier to change the timer which is largely redundant now!! 🤣 . I am looking at how to send commands to the HP via modbus to change the values that I think might make a difference, manually at first and maybe a bit further down the line with some sort automation with weather prediction via a locally run AI.

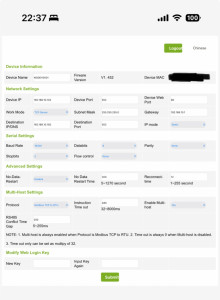

I have used the wavesure poe modbus to ethernet adapter I had a bear of a time setting it up as all the software is windows based and I am on a mac but finally got there. I couldn’t get the modbus integration to work at first (mainly layer1 issues, note to self always double check your wiring!!) and ended up spiralling into modbus2MQTT and then Node Red (total failure on my part and way too many weekends wasted because it was just the wires that were not working!) once the wires were good it was then indentation problems in the configuration.yaml file, literally line by line to get it aligned properly! And then bingo bango it actually worked! I used this project on github as my start point and they have very handily included a ton of register values from the Chofu manual. I have added this to the WC ready reckoner that @AllyFish posted (thanks @AllyFish this has been key to getting me to this point).

All of this and I am still yet to calculate the COP of the system! I need to add some better power monitoring, however seeing as my water pump is belting out a near constant 4,400rpm at least my flow rate is fairly stable at 35l/min (I think not sure how to read the flow meter! Picture attached either 35 or 28!)

Hope this helps and if you do go down the modbus route attached are my settings for the wavesure.

Regards

Si.

Kind Regards

Si

——————————————————————————

Grant Aerona3 13kW

13 x 435w + 13x 480w Solar Panels

Sigenergy 10kW Inverter

16kW Sigenstor battery

@stuartornum Thanks for this I will take a look at this tomorrow when I am less Shirazlled!! I am deffo not a coder but smash it into copilot enough times I might just be able to get it to work for me lol!!

Kind Regards

Si

——————————————————————————

Grant Aerona3 13kW

13 x 435w + 13x 480w Solar Panels

Sigenergy 10kW Inverter

16kW Sigenstor battery

@uk_pete_2000 no worries I am really standing on the shoulders of giants here and just trying to get it to work for me so happy to share.

Kind Regards

Si

——————————————————————————

Grant Aerona3 13kW

13 x 435w + 13x 480w Solar Panels

Sigenergy 10kW Inverter

16kW Sigenstor battery

Posted by: @grantmethestrengthPicture attached either 35 or 28!

They are not very clever, are they! I think that is reading 28, partly because I can cross check mine against the Midea controller's reported flow rate (assuming that is correct...).

Another reason for thinking you read off the bottom of the 'float' is the way the markings are laid out. The only way to get a reading of five (or less) is to use the bottom of the float, and when the float is at the top, the only reading available, 42, corresponds to the bottom of the 'float'.

Midea 14kW (for now...) ASHP heating both building and DHW

This thread is great!

What do people mean by efficiency? It's a word that's often quoted in relation to heating systems, but do people really understand what it means?

In my world, Efficiency = Useful energy out / energy in.

For a heat pump the equation would become:

Efficiency = "Heat into my house" / ( "Electrical Energy" + "Energy from cooling the outside air" )

A refrigeration system works by needing to condense the refrigerant against a cold fluid. The compressor increases the pressure, which also increases the gas temperature. The high temperature as is sent to a plate heat exchanger and gives up it's energy to the heating system water, that condenses the gas. The condensed high pressure gas is then rapidly depressured over the expansion valve and that gives a low pressure, cold gas. The cold gas is warmed up by the air and the loop starts again.

If the return water from the heating system is too hot to condense the gas, the expansion valve will close off and the compressor discharge pressure will go up. The higher pressure gas will condense at a higher temperature. The compressor will require extra electrical energy because it's operating at a higher pressure ratio (discharge pressure / suction pressure). The heat pump controls can fiddle with the compressor speed to try and reduce electrical energy usage, but the root cause of the increased electrical usage is the return water temperature from the heating circuit.

Running a system with a low flow temperature (ASHP leaving water temperature) will give a low return water temperature, which will minimise the required compression ratio and therefore minimise electrical power input. BUT, you still need to get the heat into the house. If you need a high flow temperature to get the energy into the house then you will need more electrical energy because your return water temperature is high.

You pay for electrical energy, so you will have higher bills if you operate with a high flow temperature.

However...the compressor in an ASHP is a variable speed, positive displacement device. Every revolution of the compressor will "squash" the same amount of gas. If you have a small ASHP, you have a small compressor. The small compressor will run at high speed to "squash lots of gas" when it's running at high power outputs (made worse if you're also operating at high flow temperature). A large ASHP will have a large compressor that would operate at a lower speed to get the same power output, which in theory would use less electrical energy.

Try driving your car on a motorway at 70mph in 4th gear, you'll use more fuel that driving in 5th gear because your engine is running at higher rpm.

The most efficient system is the one with the lowest RETURN water temperature, which will minimise the required compression ratio and use the minimum electrical energy. That will give you the maximum efficiency. Sizing the ASHP to operate at is slowest compressor speed would make sure you're using the lowest amount of electrical energy - so bigger might be better!

Regards

Bob

Posted by: @grantmethestrengthI am looking at how to send commands to the HP via modbus to change the values that I think might make a difference, manually at first and maybe a bit further down the line with some sort automation with weather prediction via a locally run AI

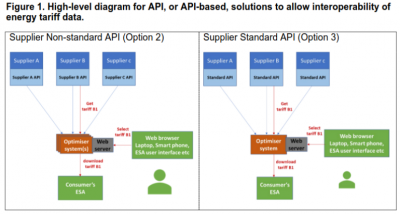

I think you ought to know that DESNZ is working on an approach to control appliances in the home using remote signalling.

At the very least they intend Off/ON commands to be sent across the internet to turn off heat-pumps when national demand is high.

But they are also working on a 'common' standard which will allow a more Smart control method using Modbus for HPs that offer it.

The strategy is called Demand Side Response, and was part of a large public consultation "Delivering a Smart & Secure Electricity System" in May/June '24.

The proposals for HP controls are in Part-1, titled Energy Smart Appliances.pdf

The working party is in progress, and is mainly looking at cyber security matters.

That's a high-level requirement because the Tariff Optimiser(s) have a database which ties together

- who owns what appliances

- your energy supplier's billing system and tariff

- data derived from your smart meter

Third-party DSR-Agents will be permitted to 'sell' you a service by which they turn off in-home appliances and credit your electricity bill with compensation.

I was a respondent, and challenged a substantial number of the proposals on technical and ethical grounds.

Typically, such consultations attract less than 100 submissions, almost exclusively from companies in the energy sector.

Save energy... recycle electrons!

Posted by: @bobtskutterWhat do people mean by efficiency?

Slight side track, but I am inclined to think that with heat pumps we should avoid the word and concept of efficiency, because the idea of something that is 300% energy efficient risks becoming an oxymoron. It implies you get something (and that something is energy) for nothing, which in a way you do, but of course you don't, it still has to come from somewhere, eg the outside air for a heat pump. I prefer the concept of performance, which of course is already in heat pump jargon, hidden away in the COP. It may also be an easier concept for a novice to grasp, if the performance of a heat pump is 3, you get back three units for each unit of energy you put in.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @transparentI think you ought to know that DESNZ is working on an approach to control appliances in the home using remote signalling.

At the very least they intend Off/ON commands to be sent across the internet to turn off heat-pumps when national demand is high.

You will own nothing, you will be in control of nothing, and you will be happy...

Brave New World just around the corner?

@transparent is absolutely right to bring this to our attention. It was clearly meant to be slipped in through the back door (almost literally) when no one was looking.

Midea 14kW (for now...) ASHP heating both building and DHW

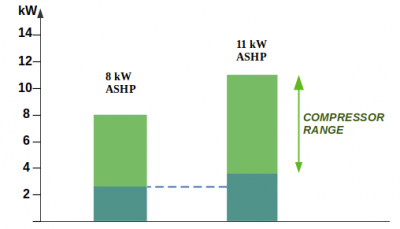

Posted by: @bobtskutterSizing the ASHP to operate at is slowest compressor speed would make sure you're using the lowest amount of electrical energy - so bigger might be better!

Ah... interesting conclusion!

I don't think that will work because compressors can't operate at very low speed.

They are designed to be used over a range which might be capable of dropping to 35% of maximum output, but not lower.

An 8kW unit might be able to operate as low as 2.8kW, but not below.

So if I fit a larger 11kW model, my lowest possible output would be higher, at around 3.8kW

Feel free to scribble over my graphic and re-post it with your own thoughts.

I can tidy it up later.

Save energy... recycle electrons!

@transparent that's a great diagram to share, it shows the design trade off that go into system specification.

Suppose we required 4kW of power to maintain a stable temperature in my house (or garage in my case 😉 )

Assuming the proposed drawings are for heat pumps with a small (8kW) compressor and a larger (11kW) compressor.

The proposed 11kW model would be operating at the bottom end of it's modulation range (36%), therefore with the slowest compressor speed and minimum electrical input - so maximum efficiency.

The 8kW unit would also work, and it would be operating at 50% of it's modulation range so potentially spinning faster than the 11kW unit and using more electrical energy.

If there was a much smaller 4kW unit it would be running flat out - which is potentially not a good situation to be in for electrical input power.

However, we do need to put our "reality hats" on. What is the realistic long term minimum power requirement? If it really is 4kW, then the 11kW unit might be a good choice. But if the outside air temperature warms up then the power required to maintain a stable indoor temperature might drop to 3kW, at which point the 11kW unit might start cycling and the 8kW unit looks best. Would a (properly designed and installed) buffer tank help in this situation?

I also suppose the large 11kW unit might defrost less because it has a larger capacity to store ice in it's air:air heat exchanger. Would this help maintain a more stable flow temperature?

I think if I was looking to choose between the two proposed units and had a 4kW "design" power requirement - I would choose the 8kW unit because it gives me some turn down (lower modulation) before going into cycling mode. Purely from an engineering point of view, the 8kW unit looks best. I would not select a 4kW unit if the design power requirement was 4kW.

Regards

Bob

@jamespa I have been quietly following all of this in amazement at some of the statements, especially about over-sized HP’s being more efficient. The comments by @jamespa are absolutely correct. Let me provide a parallel view. Imagine you are trying to heat a large metal cooking pot on a fire outside on a winter’s day and you want to keep a constant water temperature. With the right size fire the metal pot will heat up to the temperature at which balance is achieved between the heat input and the heat output from the pot which will be sustained for a constant outside temperature. If we only have a big on/off flame, we can overheat the pot by, say, 1C more and then let it cool -1C down before applying heat again. The bigger the flame the more on/offs. The average required temperature will be sustained (with hysteresis) but the actual heat energy applied to the pot will be the same regardless.

The same applies to a house. The flame is the floor in a UFH system and the pot is the room above with its internal air and its walls to the outside temperature. A UFH system with insulated floating screed floor, tog 1 carpet and 20cm pipe spacing has a fixed System Performance Factor (SPF) of 3 W/m2K. A certified Passivhaus must meet a space heating limit of 10W/m2 at peak demand. A 500 sqm Passivhaus will therefore lose 5kW at this limit. To supply constant 10W/m2 @ SPF 3 requires a delta-T of 3.33C (3 x 3.33 = 10) or MWT 23.3C for 20C room temperature (25.8C flow). If this 24 h heat load is concentrated over 12 hours and the room then left to cool for 12 hours, double the heat output is required for 12 hours, therefore the delta-T must be doubled (6.66C) with flow of 29.2C. The 24h heat loss @ 20C average room temperature is the same however you heat it. Therefore, assuming fixed outdoor temperature, you can heat constantly @ 26C flow or for 12 hours @ 29C flow with slightly worse COP. The size of the heat pump is irrelevant as long as it can supply peak 5kW load and cater for lower loads efficiently. However, a 13kW heat pump would need to demodulate down to 5kW before cycling. Below this peak demand, it will struggle. The situation with an average house losing 60W/m2 will be 6 times worse with wide COP difference. Furthermore, to say that heating constantly at 23C room temperature costs 3 times more than 12 hour concentrated heating at 20C, and therefore constant heating at 20C should not be used is frankly ridiculous. And WC is useless......🤨

Private individual. No affiliation with commercial "Heat Geeks" of same coincidental name.

-

Buffer tank required? Samsung 12kW heat pump

3 years ago

Currently viewing this topic 10 guests.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 1,184 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

That’s my pleasure, @andrewj. The only challenge now is...

By Majordennisbloodnok , 2 hours ago

-

RE: Electricity price predictions

@toodles @skd Then there is not going to be much from t...

By ChandyKris , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

@batpred I reckon Andy might know a thing or 2 about...

By Bash , 3 hours ago

-

RE: What determines the SOC of a battery?

@batpred Ironically you didn't have anything good to...

By Bash , 4 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

Here’s a current graph showing a bit more info. The set...

By benson , 5 hours ago

-

RE: Setback savings - fact or fiction?

True there is a variation but importantly it's understa...

By RobS , 5 hours ago

-

Below is a better quality image. Does that contain all ...

By trebor12345 , 5 hours ago

-

Sorry to bounce your thread. To put to bed some concern...

By L8Again , 5 hours ago

-

@painter26 — they (the analogue gauges) are subtly diff...

By cathodeRay , 6 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 9 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 12 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 14 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 1 day ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 1 day ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 2 days ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 2 days ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 2 days ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago