Shelving options for LF280K batteries

As a background, a couple of months ago Seplos failed to ship the Mason LF280 battery units within a reasonable time, so I gave up on that and came up with a potentially better solution (for the small house I live in).

Inspired by @Transparent 's horizontal battery cell solution, I'm investigating shelving options. The plan is to create a 2S16P battery, with the option to go to 3S16P (if an ASHP ever gets installed). The battery will be installed in an under stairs cupboard, so space is at a premium and I will value getting the dimensions just right. I anticipate having 4 shelves of storage, vertically packed fairly closely to minimise the vertical distance between once level and the next.

Does anyone have experience of custom made shelving (either DIY or bought in expertise)? Do you have any tips and tricks, places to look, shelving systems to recommend given my dimensional constraints (and that 48 batteries will weigh 250kg)? I would like to use enclose the eventual battery (e.g. with plasterboard or metal sides); would I be better off considering other enclosure options?

There are three factors to consider here

- the strength of the support

- the resistance to heat

- the aesthetics of the enclosure

Strength: Although I could've used a floor-mounted option, I decided to use UniStrut.

It's not unlike Meccano in its versatility, and is often used for industrial shelving. Rather than make an entire enclosure from UniStrutt, I opted for a pair of 250mm deep wall brackets with two lengths of standard channel bolted between them.

I have walls made of concrete block in my plant-room, which allows me to bolt the simpler bracket in place with no angled support required.

Unistrutt can be cut with a hacksaw, although I prefer an angle-grinder. It's faster and the sparks are spectacular! I cut down the standard wall brackets from 300mm to 250mm, and splashed out on some neat end-caps made of black neoprene rubber.

There are a number of 3rd-party equivalents to Unistrutt, many of which are interchangeable. Try ebay or TLC Direct.

Resistance to heat: Initially I assumed that LiFePO4 cells will get warm when being charged/discharged at 100A and above. This turns out not to be the case. So I'd used fire-resistant panels for the base and sides of my first enclosure, which turned out to be unnecessary.

If anything is going to heat up in use, it will be the cable connections which are too loose or incorrectly crimped.

Aesthetics: If you have a plant-room, like I do, then the final look may not be important. I actually fronted my batteries with clear, thin acrylic sheet hung from de-mountable hinges, created with FreeCAD and a 3D printer.

If you want to keep your battery within the house and unobtrusive, then consider using a kitchen wall-cupboard. Better quality ones (eg Howdens) are built using 18mm melamine-faced chipboard. A cupboard should be able to support 100Kg without difficulty, especially if supported by UniStrut below it.

If you're still worried about heat build-up from the connections, then have the cells horizontal, like mine, and fix a fire-resistant board on the inside of the cupboard door.

Save energy... recycle electrons!

This photo might help:

Unistrut wall brackets, trimmed to 250mm long, are being fitted to a timber-frame wall.

The lower 220mm of the wall is concrete block, which is why the bottom bolt is an M10 anchor/expansion type. The upper fixing is a 10mm coach-screw with a hex-head, aligned with the timber behind.

The face of the wall is 12mm thick Fermacell - a heavy cementitious wall-board into which screws can be fitted without the use of wall-plugs. Although each such screw could hold 30Kg, that would be borderline for supporting 16x 280Ah cells once the weight of the shelf, brackets and cables were added. So in this instance, all four bolts go straight through the Fermacell, without using its structural properties.

Save energy... recycle electrons!

As it happens I'm in discussion with a professional designer who is exploring the fabrication of a 'metal case' which will hold a set of 280Ah cells horizontally (as I do). There's a lot more to making an enclosure like the Seplos Mason than you might at first suppose.

At the outset, just what thickness of steel sheet could support a single 100Kg battery, and what would that add to the gross weight?! We have to think instead of folded/corrugated sheet or metal 'bar stock'.

Then there's also the safety aspect. On its own, metal isn't a good material to use at the point when the wiring is being handled. It's not just the initial installation to consider, but also future 'maintenance' such as swapping out a duff cell. If the 'technician' should drop a cable-end, it mustn't create a short circuit.

My preference is to have an enclosure system which allows 16-cell batteries to be stacked on top of each other. If the cell terminals are facing forwards, towards the 'technician', then this isn't unreasonable! Having the lid at the top mitigates against the Mason box solution. It's not great for a multi-battery site.

A pair of Unistrut wall-brackets could support two such batteries (200Kg) before additional fixing-points are required.

I'm also looking at the possible use of intumescent sheet, both for the 'door' that closes off the battery enclosure from prying fingers, but more importantly for the 'enclosure' containing the BMS units, fuses, isolators and distribution busbars to which the inverters are connected.

If our discussion here on the RHH Forum is going to form a basis of what may evolve into installation-guidance acceptable to the home-insurance industry, then we need to think carefully.

My earlier suggestion of a kitchen cupboard from Howdens was not made on a whim. But I'm exploring other directions too.

Save energy... recycle electrons!

Posted by: @transparentAs it happens I'm in discussion with a professional designer who is exploring the fabrication of a 'metal case' which will hold a set of 280Ah cells horizontally (as I do).

I'm watching this with interest! The Seplos boxes with 16 cells installed they weigh around 100kg, so should really be built in-situ, which really puts me off a Seplos. That's the advantage of a shelf approach in my mind - every piece that you deal with is a manageable weight, as you never want to move the built shelf. Are you intending a box/shelf kit that is designed to be assembled in situ ?

I notice that the Seplos boxes compress the cells - I understand this is because they have a tendency to bulge, which might damage the terminals as they tend to be rigidly coupled together. I don't know how much force is required to prevent this movement. How best to achieve this with a shelf?

Also noted, the cells are generally fitted with an electrical spacer between each.

If I do this, I'd likely go for 16 cells up front, with the possibility of 32 cells one day - our house + heating worst case is 25kWh/day, not including charging the car. Our car has a V2G charger 😎 which is great - it's a 30kWh battery already. But as I write this, the heatpump is on, and the car is parked at Mrs Robl's work 😥

Thanks for all the replies.

I should have been clearer about my own situation as space is at a premium (which is part of the reason the plan drifted away from Mason 280 boxes in the garden room). Under the stairs is a fairly constrained space as the one brick wall has the consumer unit and a vestigial gas pipe, and the opposite wall is rather old pine tongue-and-groove. Therefore the 2p16s battery (I would like the option to upgrade to 3p16s in the future) is probably best fitted to floor mounted shelves on the t&g side or else pushed to the back of the cupboard fairly tightly against the stairs. I think a fibre cement board like Hardie Backer around the shelf would be non-flamable and durable. So re-focussing part of the thread, does anyone have good experiences with free-standing shelves which could hold the 200kg - 300kg of cells?

Posted by: @transparentAs it happens I'm in discussion with a professional designer who is exploring the fabrication of a 'metal case' which will hold a set of 280Ah cells horizontally (as I do). There's a lot more to making an enclosure like the Seplos Mason than you might at first suppose.

I don't suppose you've seen the Stuart Pittaway youtube channel and his powerBASKET? It looks a very interesting setup, especially with a DIY BMS. They've gone deep into the subject!

Posted by: @roblAre you intending a box/shelf kit that is designed to be assembled in situ ?

Yes. I'm imagining a modular system whereby one enclosure can be placed on top of the other. If the cells are horizontal, then there's no need to disconnect any batteries which are already in operation below the new one being added. But each layer must be capable of supporting those above.

The designers around me are very much in 'listening mode'. So feel free to chip in if a thought crosses your mind. 🤔

Note also... these are not my company employees. This is a combined effort between engineers across different companies who are all bringing particular expertise and experience to bear. There may well be more than one 'product' which emerges from such collaboration. A suitable enclosure is just one of several jigsaw-pieces which are needed in order for the UK to transition to an electricity system which is:

- flexible in its operation; in harmony with our increasing generation from renewable sources

- fully Time of Use in character, administered via our Smart Meters

- resilient against outages, both from physical damage (storms) and also from hostile attack from foreign adversaries

- able to flatten the surges/peaks which presently require us to install over-specified transformers and grid-cabling

- supportive of nodal-pricing; lower prices for using electricity generated closer to the point of demand; reducing our dependency on National Grid centrality

- biassed in favour of those with lower demand; positively 'unfair' to best benefit households in fuel poverty, those in receipt of assistance from food-banks, those on the PSR etc

These are all BIG subjects in their own right... and way off-topic!

If you particularly want to discuss strategies to meet these objectives, then start a new topic with a broad-enough title and I'll expand on these points over there!

Save energy... recycle electrons!

Cell compression. Thanks for raising this @robl

I'm in two minds about this. Apart from the possibility of mechanical strain on the terminals, there is scant evidence to suggest that a cell suffers any 'damage' from swelling.

There are flexible busbars available. Some have a double-bend in the middle, whilst others are made of a woven copper braid. Each method is able to cope with variations in terminal distance.

Cell expansion is mainly reported by those who charge their battery to full capacity, which is less likely for home-storage.

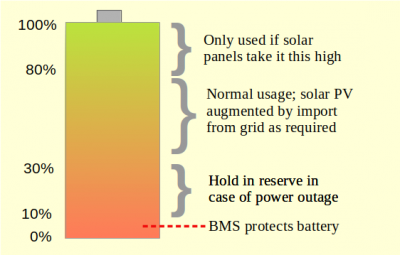

I would expect a home storage battery to be used like this:

Save energy... recycle electrons!

Posted by: @chickenbiga fibre cement board like Hardie Backer around the shelf would be non-flamable and durable

Even though I feel that fire-resistant boards are more important for the fuses/trips than the LiFePO4 cells themselves, I have explored this subject extensively. May I therefore offer the following advice....

HardieBacker board (for tiling) is brittle. The central 'cement' layer relies on the outer mesh fibres to keep it intact. Try screwing it to a timber-stud wall, with the screw too close to the edge and you'll see what I mean!

I've got some (large) offcuts of Cembrit, which is the sort of exterior cladding which should've been used on Grenfell Tower. Cementitious exterior cladding is now much more widely used, but it is heavy. You should be able to pick up some reasonable offcuts by having a word with the site manager building any commercial property nearby. If he won't take cash, a 4-pack of beer is a good opening offer.

The Fermacell I mentioned above is a cementitious wall board for interior use. It's much cheaper than buying purpose-made fire-resistant board, and is also available as 1/4-sheet handi-boards (1200x600mm).

Cementitious boards can be cut with a special circular saw blade, which usually has just four teeth. I use a 165mm diameter one made by Makita on a Triton track (plunge) saw.

Exterior cementitious board requires pre-drilling to accept screws/bolts. I've used tile-drills of three different types, all of which have proved successful. To avoid over-heating, hold a wet sponge against the side of the bit as it rotates.

Interior cementitious boards can be screwed without a pilot-hole, but the required 'dry-wall screw' has a different angle on the bugle-head when compared with the type used for plasterboard. Use the right one!

Fermacell make their own PU jointing glue which can edge-join boards together when building a complete wall. I've also tried Gorilla Glue successfully, as it's a PU type too. Wet the area to be glued first.

There are other cementitious boards available, including some that resemble timber-cladding. Look online, or visit a local builders' merchant such as Travis Perkins or Jewsons. They may well have a full sheet with a broken corner/end, which you can buy at half-price. 😉

Save energy... recycle electrons!

Another photo - this time showing two horizontal Unistrut bars on which a 'shelf' will be fixed.

I've fixed these bars 'upside down' in order to maximise the surface area of the steel which will support the underside of the shelf. Instead of the usual M12 Unistrut hex-headed bolts, I've used M10 cap-headed screws. These hold the bar using a square 'washer' visible at the end of the front bar. The bolt is tightened using an allen-key from above, leaving no head protruding.

@chickenbig - I think those wooden stairs would benefit from having fire-resistant boards screwed below each tread anyway. It makes the escape route safer!

Each riser is probably not very different in height than the 172mm of a 280Ah LiFePO4 cell on its side. So you could fit one row of cells per step. You'd have the first home storage battery in a diagonal-shelving arrangement 😉

I would use Unistrut-style metalwork, but with verticals bearing directly onto the concrete floor below. That would take the weight rather than using the T&G boarding to hold anything. You could double-secure each rhs upright in place using a wall-bolt into the brick.

Save energy... recycle electrons!

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 218 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

@transparent Triggered by the various commen...

By JamesPa , 16 minutes ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 46 minutes ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 53 minutes ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 1 hour ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

I've found that generally the humidity in the house is ...

By IRMartini , 1 hour ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@benson — as @tasos suggests, plotting multiple variabl...

By cathodeRay , 5 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 6 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 17 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 19 hours ago

-

RE: Setback savings - fact or fiction?

I also need to correct something I said by mistake earl...

By cathodeRay , 19 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 22 hours ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 22 hours ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 22 hours ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 24 hours ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago

-

RE: New Vaillant aroTherm Plus in black - When will it come to the UK?

@majordennisbloodnok Daikin, take note! (In fact, I hav...

By Toodles , 2 days ago

-

RE: Midea ASHP – how to set weather compensation

@mk4 — good work! First, I agree, no evidence of cycl...

By cathodeRay , 2 days ago