Posted by: @amanda1I am assuming the compressor is inside the Monobloc? But is the condenser in there as well?

Yes. On your model, the compressor and condenser are both within the external unit.

That means the refrigerant only occupies that small amount of piping.

There is a pumped loop containing water (& glycol?) which picks up the heat from the condenser and transfers into the cupboard in your photo.

This is the all-important pipe which others refer to when they mention the Leaving Water Temperature.

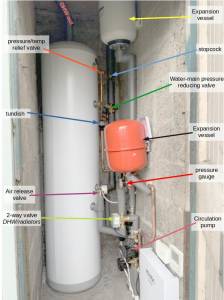

The following diagram is the basic minimum explanation of what's in that cupboard.

If you want more detail, post a photo from a different angle to let me see what's on that right-hand wall.

Who's going to be the first to comment on the inadequate pipe insulation?

Save energy... recycle electrons!

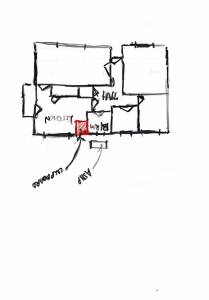

@transparent that cupboard is a minor cause of concern for me. I knew someone would notice that….It was the only suitable location for the cylinder. It is inset into the house, surrounded by the house (by breeze block walls which might be single layer at that point) on three sides, kitchen (and cooker) on one side, hall at the back and a bedroom on the other side, with an outside door, It has always been quite warm and absolutely dry in there. I have now insulated the inside of the door with foil insulation and I have a thermometer in there that registers max temp, current temp and lowest temp. On nights when the outside temp has dropped below zero the cupboard has stayed at about 13-15. It is directly behind and to the side of the pump. The water temperature - takes about 15 hours to drop very very gradually from 50 to near to 40. I am considering putting further insulation on the inside of the door/ replacing it with an insulated door. If push comes to shove eventually it might be possible to block off the outside door and open up the back wall with a door assuming that there isn’t any pipe work immediately behind the cylinder. I have tried to tell myself that the door is less than the size of the large kitchen window if you know what I mean in terms of letting in the cold/letting out heat….

@transparent Yess!! I was wondering if I needed to add pipe insulation! Thanks for the labels - it’s really helpful.

It's difficult to tell from the photo, but I'm assuming the pipe insulation has a 13mm wall thickness.

That's not enough for a cupboard which is outside the house.

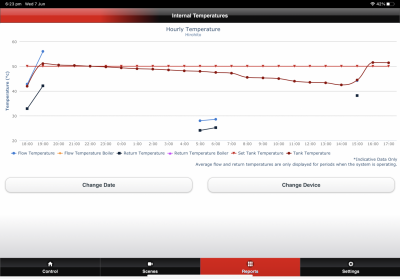

Remember, the controller is trying to balance a couple of pipes running to/fro the outside unit, which should have a temperature difference between them on only 5°C

If you throw away 20% of the energy in that cupboard, how the heck can it get enough heat into the actual house?

Save energy... recycle electrons!

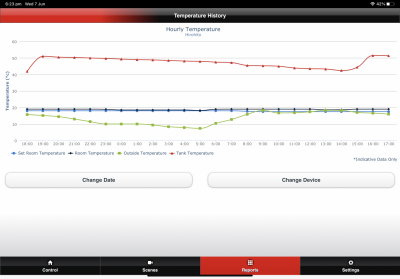

@transparent these are the Melcloud reports for the last 24 hours re Flow Temp, Return Temp, and HW temp, and outside temp.

Your sketch of the house' plan view is just what's needed @amanda1

Let's look at three issues relating to wasted heat:

1: Yes, that external door needs to be one with decent insulation within it.

If it were me, I'd buy a very ordinary Ledged & Braced (L&B) external door, line the inside with multifoil insulation (approx 20mm deep), and then add an inner sheet of 9mm ply.

Some ingenuity is required to space the ply off the back of the door. The spacers mustn't act as thermal bridges.

For most tradesmen, I'm pretty sure they'd use wooden battens.

I'd probably use off-cut strips of PVC weatherboarding... because I happen to have some!

There must be no draughts between the door and the frame.

Use foam strip on the door-stop timber, and a brush-type draught-excluder where it meets the floor.

I keep off-cuts of EPDM (rubber) roof sheeting, which I use to also seal the inner/hinge side of doors.

2: All the copper pipework around the DHW cylinder needs to be lagged using 19mm wall-thickness insulation.

Each section should be bonded to the next (contact adhesive is good).

If the corners aren't a good fit, then overlay the join with insulation tape.

Personally I prefer the black neoprene rubber insulation. It's usually referred to as Class-O, which is a specification used within the refrigeration industry.

The most common trade name is Armaflex, and BES stock a good range of sizes.

The insulation should cover all of the brass you can see on the valve bodies!

I bought lengths with 42mm and 56mm internal bore, which I cut to the required shapes with a sharp knife.

Any hot water cylinder requires insulation on cold water pipes which connect to it, up to a minimum 1m in length. Heat passes back through the 'cold' water.

But in your case, I'd also wrap the two expansion vessels because heat will rise up into them.

Either use Armaflex-style neoprene foam sheet, or multifoil held with aluminium-duct-tape.

3: The insulation is particularly important on the pair of pipes which lead between that cupboard and the outside ASHP unit.

The pipes should be insulated right through the holes in the wall.

As it's external insulation, it needs to be UV-resistant. This is most often sold as "solar" pipe insulation because it gets used on solar-thermal panels fixed to a roof.

Once again, you'll need a larger bore to cover the valve bodies, which are probably close to the external ASHP unit.

It must not be possible for any rainwater to pass inside the external insulation.

Otherwise it will run between the insulation and the metal pipe itself, removing heat and then dripping onto the ground.

Save energy... recycle electrons!

@transparent Many many thanks for this. These are things I can do myself which is good. Here are some shots of the door and the pipes on the exterior from the pump to the interior. At the moment the old cavity wall insulation has been removed and I am awaiting the new cavity wall insulation . When I opened the cupboard I discovered that they had blown lots of old insulation into the cupboard (well, I am praying that it is insulation and not asbestos….. this is a 1960s house ) and I am hoping that that hasn’t messed anything up - I will have to get the hoover out to it. I am fairly sure there’s scope for more insulation on the outside pipes. Can I put insulation over those big nuts connecting the pipes to the pump?

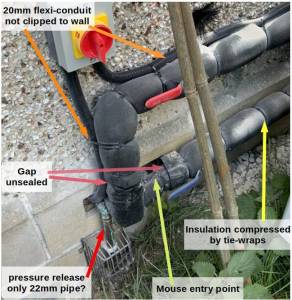

Let me pick up just two of your last set of photos, @amanda1

And I'll now answer your previous comment regarding the context in which I'm talking with politicians.

The new set of Building Regulations, Part-L, comes into force on 15th June (next week).

Your installation doesn't even pass the existing Part-L... and nor does the extent of the documentation and training you've been supplied with.

I realise that you're in Scotland and I don't have information on how your Building Regs are actually applied.

But in England, our Local Planning Authorities (LPAs)receive the Part-L Notification from an MCS-approved installer, and simply issue the certificate.

Unlike the Part-P certification from qualified electricians, there are no professional bodies which check the standards.

MCS is being (incorrectly) treated as if it were a trade association and examination authority, like NICEIC.

The Councillors elected to my LPA are no longer willing to undertake such an administrative exercise.

They are unhappy that their Council's name appears to be providing an assurance of compliance with Part-L which is entirely unsubstantiated.

As we live in a democracy, they are eager to discuss the possibilities with me.

As a rule, Councillors are very willing to talk to anyone who who highlights a waste of their staff's time on a pointless exercise... and better still, that I am suggesting some alternative ways forward. 🙂

Last week I visited the home of an elected Councillor, who was delighted to show me his ASHP in a very beautiful barn-conversion.

As with all other HP installations I've ever seen, his failed for the same points that yours does.

So I took some photos in order that the Executive Officers and Building Control staff can see the actual status of what they're issuing Part-L certificates for!

Why don't you try the same approach?

Send copies of the photos I've annotated to your local Councillor and ask if this is the standard of installation which your LPA is happy to authorise as complying with the Building Regulations?

Give him/her a link to this discussion with you (which actually started 7-pages ago!).

The usual response is that they believe your site to be an exception.... but it's not.

This is happening all the time because the MCS accreditation is unenforceable.

The British Government's current response is "we are aware of deficiencies, and are further tightening the standards required by the regulations."

But that's not going to work, is it?!

Installers with MCS approval have an enormous waiting list of potential customers.

They have no incentive to spend an extra 12-hours on each site getting the insulation correct, still less trying to tell the occupant how the system works!

And they're certainly not going to create the schematics and instructions for each individual property they work on... the Building Regs can go to 'L' !

Save energy... recycle electrons!

@transparent quick answer to one if the points in your labels: the brush strips are temporary plugs, the cavity wall insulation has yet to be put in (next Monday). Then the holes will be sealed.

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 427 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

Without knowing it, @andrewj, you've laid down the gaun...

By Majordennisbloodnok , 19 minutes ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 23 minutes ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 56 minutes ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 1 hour ago

-

RE: Setback savings - fact or fiction?

@cathoderay The input power is largely determined by...

By RobS , 2 hours ago

-

RE: Electricity price predictions

@transparent Im impressed by all your work on this. ...

By JamesPa , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 4 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 4 hours ago

-

RE: What determines the SOC of a battery?

I agree. Fogstar confirmed that the Seplos BMS does ...

By Batpred , 4 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 6 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 9 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 20 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 22 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago