@bobtskutter - thanks as ever for your detailed replies. By the way, if you do want to use quotes from posts, just select the bit you want to quote and a popup should appear under the selection with a double quote mark in it. Click that and the forum back end should do the rest for you. Make sure before you do the selection and clicking the cursor is where you want the quote to end up. Having said that, I do like to be selective with quotes, just quoting whole posts just adds bulk without substance.

Posted by: @bobtskutterHow did I calculate the secondary flow rate?

OK, got it.

Posted by: @bobtskutterThe answer to that is "a very large number". So that means your secondary circuit requires a large amount of head (or "pushing force" if you like) to get the water to flow through it. Something is wrong.

I agree, hence my earlier mention of a sanity check!

Posted by: @bobtskutterDo you have a pump curve for your pump, there might be one in the manual?

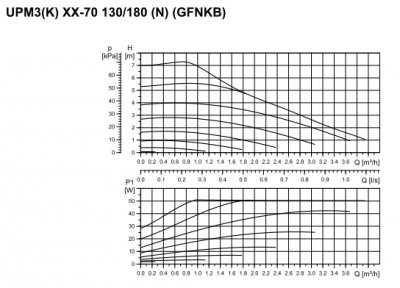

There is, here it is (at least I think this is the right model, the manual covers dozens of similar but different models):

Posted by: @bobtskutterCan you open all the lock shield valves?

Yes. I'll try to pick a useful time to do this, ie when it is cold and demand is high (and I am around to do it!), so may not be for a while.

Posted by: @bobtskutterPlease can you confirm if those are the dimensions of the PEX

Yes, the PHE itself (excluding foam). Because of the foam they are approximate. It doesn't help the the thing is jammed between floor boards, bottom half almost inaccessible.

Posted by: @bobtskutterThat's just wierd. The ASHP was working OK, then it stopped behaving.

I agree, as you say, that is why I started this thread!

Posted by: @bobtskutterYou said you've got a script which automatically adjusted the weather compensation curve. That sounds like you've created some sort of "room demand override" - which is very cool. But could that be making the compressor speed up for no apparant reason?

I don't think so. It a very simple script. It checks the actual IAT against the desired IAT once an hour (10 mins past) and if there is a discrepancy then it moves the WCC up or down one two or three degrees (by setting the end points) depending on which way it needs to go. That means I don't have to meddle with the Set LWT itself, instead I just set the thing that sets the Set LWT. I have various safeguards to make sure it never creates a situation where the Set LWT will go over 60 degrees.

Midea 14kW (for now...) ASHP heating both building and DHW

Posted by: @cathoderay

^Hey, look at that, it worked 🙂

OK, This is a pump curve. The top one shows Head against volumetric flow at different pump speeds. The chart shows 8 different curves, so that makes me think that's for a pump with infinitely variable speed (some pumps have a dial and not buttons). Your pump has 3 different curves so I don't think thats for your pump. BUT, it doesn't really matter, what it does show is at max speed, 1.8m3/hr the head is 5m, or almost 50kPa. That's a lot of pressure drop to get the flow around your radiators!

I looked up the vendor for your PEX and got to the Hexonic website. Their web catalogues show PEX size but don't quote heat transfer coefficients - which is annoying. I did some searching and found Hisaka, they have a web simulator.

You have a brazed plate heat exchanger, probably with 3/4" threaded connections. These are bog standard in the HVAC world, you'll find them everywhere. There one inside your ASHP, combi boilers use them, even your car probably has one to cool the gearbox oil or engine oil. There's not much difference in the way the plates are designed so any differences between the units are going to be very small. Anyway, using your dimensions I get a PEX design of about 35kW. If you're interested set the following:

Brazed Model / Stainless / copper / Liquid-Liquid

Hot - Water / 50 / 45 / 6

Cold - Water / 45 / 40 <leave the flow blank>

Click calculate, then look at the specification pdf.

The calculated external dimensions are 303x103x122. Similar to yours but not an exact match (smaller infact!).

You need to set a very large flow so it doesn't pinch.

The PEX you have appears to have a lot of heat transfer surface area, a lot more than it actually needs to transfer 8kW. This is why it's pinched between the primary_in and secondary_out.

Note the Hisaka datasheet says 0.038MPa pressure drop at 6m3/hr. That's 38kP at 6m3/hr or 38 x 1.8^2 / 6^2 = 3.4kPa at 1.8m3/hr

PressureDrop is proportional to (volume flow)^2. So there's still a lot of pressure drop being used up in your secondary circuit.

I hope this shows the PEX is actually big enough, it's actually too big. It's the flow in the secondary circuit that's too small.

Regards, Bob

(who has worked with compressors that consume MW of electrical power, heat exchangers that are larger than articulated lorries and pumps which are bigger than your average car)

Posted by: @bobtskutterThe chart shows 8 different curves, so that makes me think that's for a pump with infinitely variable speed (some pumps have a dial and not buttons). Your pump has 3 different curves so I don't think thats for your pump.

That's a reflection of the impenetrability of the Grundfos literature, It really is some of the worst technical literature I have ever seen!

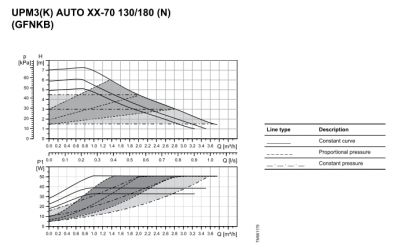

This is from another of their manuals:

The pump I have has the same label text (though appearance is different) as the one shown bottom left (UPM3 AUTO). But it is NOT the same pump, the LEDs are different (mine has two green and three amber, above pump has one green and four amber). The problem I think is that there are two variants of the UPM3 AUTO, distinguished by the LEDs (1 green 4 amber and 2 green 3 amber) which means the settings are different eg you can't have four amber lights on on the second variant (the one I have). This is my secondary circuit pump, looks a bit odd because photo was taken when it was upside down, and I have inverted it to make it easier to read:

Decoding the spec:

UPM3 is the pump range and AUTO is the type of pump (Auto may or may not mean 'standard', which may mean no external control, ie it is 'auto')

25 - 70 is the nominal diameter (but is ambiguous) and 7 is the max head in metres

130 is the housing (cast iron, 130mm)

ZZZ - who knows? Perhaps the idiot behind all this crap dozed off.

The bottom line is I don't think we know what pump is actually doing. It is set to CC3 (Constant Curve 3) which the (correct? I think this is the correct one) manual describes as follows:

which leaves me none the wiser as to whether this achieves the maximum flow rate. 'Speed' is ambiguous: is it the rotational speed (RPM) of the flow speed (rate, in m^3/h)? What if the hamster is running fast (high RPM) but it is not going anywhere (no flow rate) etc etc?

Put another way, which setting of the three settings (Proportional Pressure (PP), Constant Pressure (CP) and Constant Curve) actually gets the fastest flow rate? Each setting has within it three settings, 1, 2 and 3 (low, medium and max). For CC, the 1-3 settings appear to control the head (see above) - but CC is about the speed - 'it runs at a constant speed' and then adds 'or power' - what does that mean? There is also an AutoAdapt setting. What effect does that have when used? This is only available in PP and CP modes, but what does it actually do? According to the manual:

"The AUTOADAPT function enables the pump to control the pump performance automatically within a defined performance range.

• Adjusting the pump performance to the size of the system.

• Adjusting the pump performance to the variations in load over time."

Might that be useful? Does anyone actually know?

Posted by: @bobtskutterI hope this shows the PEX is actually big enough, it's actually too big. It's the flow in the secondary circuit that's too small.

I take this to mean it is big enough to handle the transfer of heat, which by implication I think also means it can handle sufficient flow (otherwise it wouldn't transfer enough heat). If it is flow in the secondary circuit that is the problem, is that because the resistance is too high, or the pump too feeble? Apart from opening all the lockshield valves, the resistance is what it is. I can't see that it can be that great, 10 mostly K3 rads on 28/22/15mm copper tube with fairly direct runs in a smallish to medium size house. That just leaves the pump, and its numerous numbers meaningless to man. What setting do I use to get maximum flow?

I have now come across this chart in the manual, which does appear to show three curves for each mode, and I think at last is the right chart for my pump:

I think the chart shows that for any given head (resistance? - but head is pressure???) CC3 will always give the max flow, which I think is why I am on CC3. Going into the chart the other way (from the X axis), if my flow rate is 1.9m^3/h, then the chart says it is pushing against a 'resistance' of 45kPa or 4.5M of head. But the resistance is fixed, so the flow rate must be fixed? Isn't that what the chart tells us? In other words, the flow rate is determined by the resistance, and as the resistance is fixed, that means you can't alter the flow rate, because the pump only has so much oomph? Might a more powerful (more oomph) pump do better, if one exists that will fit in the available space?

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay digging into further dirty details are your fully open trvs suitable for bidirectional use or are they your secondary constriction?

2kW + Growatt & 4kW +Sunnyboy PV on south-facing roof Solar thermal. 9.5kWh Givenergy battery with AC3. MVHR. Vaillant 7kW ASHP (very pleased with SCOP 4.7) open system operating on WC

Posted by: @judithdigging into further dirty details are your fully open trvs suitable for bidirectional use or are they your secondary constriction

Good point. I think they are (mostly) bi-directional. They are a mix (what was on the shelf at the time...). Six are Inta i-therm (definitely bi-directional according to the packaging), one is a Drayton (also bi-directional according to the packaging). One of the remaining three is unclear (instructions that came with it say connect following the flow direction arrow on the body, but I can see two arrows, one pointing each way...) and from the rad temp gradient it is probably on the return, one is a complete unknown, and appears to be possibly on the flow side and one (in the utility room) is totally inaccessible, but that radiator is not in use )off at the lock shield end. In summary, at least 70% claim to be fully bi-directional, the other three are a bit of an unknown with no obvious way of finding out

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay It would be classed as a very long shot perhaps, but it might be worth opening the LSV (and ensuring the TRV is also fully open) just as a temporary measure just in case the pipework in that area is harbouring an airlock. The increased flow might just dislodge any such air bubbles. If it doesn’t help, well you haven’t lost anything and can close the valves very readily again. Just a thought. Regards, Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

@toodles - a while back I went one further (it has always been a slow to heat up radiator at the end of a run), closed down all the other rads to all the flow went through that one rad. Unfortunately it didn't make any difference...

I have now done a bit more detective work and it turns out one of the unidentified TRVs is a Screwfix Direct one, which Screwfix claim in the spec is bi-directional, despite the confusing instructions. The Q&A for the item also has this: "The valve will have 2 arrows cast into the valve body in opposite direction, indicating that it is bi-directional and can be fitted to either side of your radiator." That now means 80% of the TRVs are apparently bi-directional.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay So a beady eye on the other 20%? Toodles.

Toodles, heats his home with cold draughts and cooks food with magnets.

@toodles - I have been crawling around on the floor fixing them with a very beady eye (the utility room one it turns out is just visible) but have been rewarded more with beads of sweat than beads of insight.

Midea 14kW (for now...) ASHP heating both building and DHW

@cathoderay Perhaps you need to adopt a ‘Paddington Stare’! 😉

Toodles, heats his home with cold draughts and cooks food with magnets.

Hello, I can explain all the pump curve information, but it will take a while for me to put some pictures together. For now, lets work on the basis that the pump is operating at 1.8m3/hr and 45kPa (45,000 Pa <- this is important).

If you look at the technical manual for Classic K3 radiators from Stelrad

There's a chart on page 5 which shows pressure drop vs flow.

1.8m3/hr is roughly 1800kg/hr (assuming water).

If you have 15 radiators and a perfectly designed system, each radiator would get 120kg/hr of water.

If 120kg/hr of water flowed through one Steltrad Classic K3 radiator it would create a 200Pa pressure drop. Your system has a 45,000Pa pressure drop. Those two numbers should be very close together, but they're not (You have about 225times more pressure drop in the system than you should do). That means something is adding extra pressure drop to the system.

It could be your lock shield valves, please open all of them if you can do.

It could be your main flow and return lines are very long and small diameter pipe, but I doubt that. My money is on a valve being almost fully closed in the secondary circuit, or there is a mesh filter somewhere that's blocked.

If you open every valve on the secondary circuit, additional pressure pressure drop will reduced and only the pipework frictional pressure drop will remain. The pump wont need to put up so much differential pressure and its operating point will move towards the right, i.e. it pumps more liquid - which is what we're trying to do.

Regards

Bob

@bobtskutter - thanks again.

Posted by: @bobtskutterIt could be your main flow and return lines are very long and small diameter pipe, but I doubt that. My money is on a valve being almost fully closed in the secondary circuit, or there is a mesh filter somewhere that's blocked.

Main flow and return lines are not exceptionally long and are of reasonable bore (28 > 22 > 15mm), I agree unlikely to be the problem. It if is a (ie one) almost fully closed, then that still leaves 9 open... The only filter I can see in the secondary circuit is the Flomasta Magnetic Filter, which does have a brief stretch of 22mm copper pipe either side of it.

Posted by: @bobtskutterIf you open every valve on the secondary circuit, additional pressure pressure drop will reduced and only the pipework frictional pressure drop will remain. The pump wont need to put up so much differential pressure and its operating point will move towards the right, i.e. it pumps more liquid - which is what we're trying to do.

I think I get this, but what do I measure so we can see what actually happens to the secondary flow rate? I presume it has to be the PHE secondary in/out (and primary in/out?) delta t? I do have reservations about how accurate those readings are. Another test that might work is opening them all up during a very low (zero or below) OAT and see what happens the the heat pump's kWh out. But that means waiting for another cold spell.

Explaining how to use/read those water pump curves won't be time wasted at all. I am sure I am not the only one who finds them awkward.

Midea 14kW (for now...) ASHP heating both building and DHW

- 27 Forums

- 2,495 Topics

- 57.8 K Posts

- 310 Online

- 6,220 Members

Join Us!

Worth Watching

Latest Posts

-

RE: Electricity price predictions

I am always impressed with how you keep abreast of so m...

By Batpred , 38 seconds ago

-

RE: Setback savings - fact or fiction?

I fully understand your reasoning, same steady inputs s...

By cathodeRay , 10 minutes ago

-

RE: Humidity, or lack thereof... is my heat pump making rooms drier?

@majordennisbloodnok I’m glad I posted this. There see...

By AndrewJ , 31 minutes ago

-

RE: What determines the SOC of a battery?

@batpred I didn't write the Seplos BMS software, I a...

By Bash , 2 hours ago

-

RE: Testing new controls/monitoring for Midea Clone ASHP

@tasos and @cathoderay thanks. I have some history grap...

By benson , 2 hours ago

-

I am having my existing heat pump changed to a Vaillant...

By trebor12345 , 3 hours ago

-

Our Experience installing a heat pump into a Grade 2 Listed stone house

First want to thank everybody who has contributed to th...

By Travellingwave , 3 hours ago

-

RE: Solis inverters S6-EH1P: pros and cons and battery options

Just to wrap this up here for future readers: The S...

By Batpred , 6 hours ago

-

RE: Struggling to get CoP above 3 with 6 kw Ecodan ASHP

Welcome to the forums.I assume that you're getting the ...

By Sheriff Fatman , 6 hours ago

-

RE: Say hello and introduce yourself

@editor @kev1964-irl This discussion might be best had ...

By GC61 , 8 hours ago

-

@painter26 — as @jamespa says, it's for filling and re-...

By cathodeRay , 11 hours ago

-

RE: Oversized 10.5kW Grant Aerona Heat Pump on Microbore Pipes and Undersized Rads

@uknick TBH if I were taking the floor up ...

By JamesPa , 22 hours ago

-

RE: Getting ready for export with a BESS

I would have not got it if it was that tight

By Batpred , 24 hours ago

-

RE: Need help maximising COP of 3.5kW Valiant Aerotherm heat pump

@judith thanks Judith. Confirmation appreciated. The ...

By DavidB , 1 day ago

-

RE: Recommended home battery inverters + regulatory matters - help requested

That makes sense. I thought better to comment in this t...

By Batpred , 1 day ago

-

Bosch CS5800i 7kW replacing Greenstar Junior 28i

My heat pump journey began a couple of years ago when I...

By Slartibartfast , 1 day ago

-

RE: How to control DHW with Honeywell EvoHome on Trianco ActiveAir 5 kW ASHP

The last photo is defrost for sure (or cooling, but pre...

By JamesPa , 1 day ago

-

RE: Plug and play solar. Thoughts?

Essentially, this just needed legislation. In Germany t...

By Batpred , 1 day ago

-

RE: A Smarter Smart Controller from Homely?

@toodles Intentional opening of any warranty “can of wo...

By Papahuhu , 1 day ago

-

RE: Safety update; RCBOs supplying inverters or storage batteries

Thanks @transparent Thankyou for your advic...

By Bash , 1 day ago

-

RE: Air source heat pump roll call – what heat pump brand and model do you have?

Forum Handle: Odd_LionManufacturer: SamsungModel: Samsu...

By Odd_Lion , 1 day ago

-

RE: Configuring third party dongle for Ecodan local control

Well, it was mentioned before in the early pos...

By F1p , 2 days ago

-

RE: DIY solar upgrade - Considering adding more panels

I know this is a bit old, but it made me wonder what co...

By Batpred , 2 days ago