Preparing for 2nd winter in new build house.

Firstly, apologies for what is likely to be a long post. We have a complex setup that will take a bit of explanation.

We completed our new build in Sussex almost a year ago and moved in at the end of November 2024. The house is brick and block construction and was still very much drying out when we moved in given the wet weather we had had all through the build and the traditional plastering method that was used internally.

We have two separate mains power supplies entering the property: one supplies the power for the house and one EVCP and the other supplies the ASHP, some AC and another EVCP. We have solar PV and a Powerwall 2 on the house phase. This means that the ASHP does not benefit from any other power sources.

The ASHP and UFH system was designed by Nu-Heat (we didn’t have a choice in this) and they have provided a room-by-room heat loss calculation. Most of the rooms have thermostats.

Until I found this forum, we had 4 zones in the house: reception rooms, bathrooms, bedrooms and unused rooms. Having read some of the posts here, I’m reducing the number of zones. The ASHP phase is on the Cosy Octopus tariff, so we have to set back all zones during the expensive period in the afternoon. Currently the set back is significant enough to stop the ASHP coming on at all. As I mentioned, we don’t have any alternative power source on this phase, so it’s entirely dependent on the grid. I realise that such a large set back is likely to be adversely affecting the efficiency of the heat pumps. I’d be grateful for any advice from other users of this tariff.

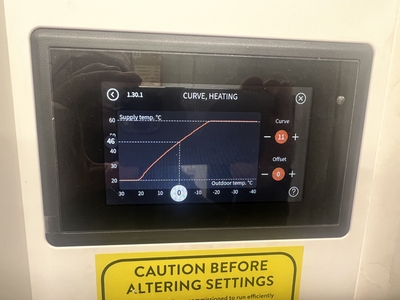

I’ve attached a photo of our heat curve. Firstly, it looks like the maximum supply temperature that’s been set by the installer is very high at 60°. I feel like I should reduce this. I’m also considering undertaking the task that is detailed on this forum of using the thermostats as limiters and just using the weather compensation curve on the heat pump. I’ll wait until the weather is colder. The Weather Control setting is currently off. There isn’t a lot of information about what this actually does, but it would seem that it checks the weather forecast and adapts its behaviour accordingly. I would be grateful if anyone has any knowledge of this feature and whether it’s worth enabling.

If I believe the year-to-date data provided by the heat pumps, I have a SCOP of 4.24. I don’t know how accurate this is likely to be and we haven’t hit any cold weather since the spring.

My main question is am I doing everything I can to make the system as efficient as possible? I am a bit of a tech geek, but this is the first time we’ve had a heat pump so I’m still learning. On the other hand, I don’t want to be completely obsessive over this (I have that tendency) so I’m not planning to constantly tweak. I just want to be sure it’s set up efficiently and then I can leave it alone.

We are happy with the temperature in the house for the most part. Our bills were higher than we’d like last winter, but I know that is in part due to the house drying out.

Thanks in advance for your help with this.

Forum Handle: sbm74

Manufacturer: NIBE

Model: 2x F2040-16

Type: ASHP

Arrangement: Mono

Area of Country: West Sussex

Home Type: House

Size: 650m2

Insulation Level: 2024 Cavity wall new-build

Heat Loss Calculation: 22.1kW @ Amb. Temp, of: -3 °C

Type of Controller: Room thermostats

Type of Control: Room Temperature

System Type: UFH throughout

Total Output of Heat Emitters: kW

Buffer Tank or Low Loss Header: BT 215 litre

Secondary Pumps: 1 DHW return

Solar PV System: 4.2kW on different phase

Power Diverter: No

Battery System: Tesla Powerwall 2 14kWh on different phase.

What an interesting and ambitious project. You certainly have built a big house - 650m2 is enormous!

Here are some pointers:

- I wonder why you have 2 x single phase power supplies. With 2xEVCPs, 2x16kW heat pumps, ovens, tumble dryer etc, I suppose you might exceed 100 amps, if they were all on at the same time. In that case, one 3-phase power supply might have worked better.

- Our 1968 house is a 5 bedroom detached, with three bathrooms, but it is “only” 350m2. It has a calculated heat loss of about 15kW, though I suspect it is less. Your new house must have much better insulation, so it may be worth checking the heat loss calculations in case 22kW is too pessimistic. Your system may be able to tell you how much heat the system actually generated during the winter months.

- Your heat loss calculations should include a design flow temperature at the target outside temperature of -3C. I would hope for a number of maybe 35C. Certainly, a 60C flow temperature in an underfloor heating system is much too high. A hot shower is about 40C. A floor at 60C would burn your feet and ruin your floor. I am not an expert, but I think even 40C UFH is considered dangerous. Therefore, set the weather compensation curve carefully before you turn it on.

- I would investigate whether your system provides any reports of compressor frequency, outlet and inlet flow temperatures, electricity consumed, power output, COP and SCOP, outside temperature, indoor temperature…. Ideally, you would download this in .csv format in 30 minute intervals over the winter months, so that you could analyse it with Excel. Some system provide their own graphical analysis, which may well be good enough. Looking at compressor frequency tells you how often the heat pumps turned on and off. Ideally, you want them to run continuously at a low flow temperature, because that consumes less electricity.

i hope that helps.

Grant Aerona 290 15.5kW, Grant Smart Controller, 2 x 200l cylinders, hot water plate heat exchanger, Single zone open loop system with TRVs for bedrooms & one sunny living room, Weather compensation with set back by room thermostat based load compensation

The electricity supply:

Posted by: @grahamfI wonder why you have 2 x single phase power supplies. With 2xEVCPs, 2x16kW heat pumps, ovens, tumble dryer etc, I suppose you might exceed 100 amps, if they were all on at the same time. In that case, one 3-phase power supply might have worked better.

I too am very surprised at this.

I don't understand why the DNO didn't insist on this being a 3ph supply!

The threshold at which a domestic property should be 3ph is 60A per phase.

Yes, the Service Fuse is usually 100A,

but the Electrical Networks Association has ratified a strategy to replace those with 80A.

As this is a new-build, it should have 80A cut-outs.

[See this explanation from NGED, who operate four of the DNO regions]

Secondly, 3ph heat-pumps are more efficient because the condenser/pump is operating with 440v across the windings, not 240v

Thirdly, a 3ph domestic EV charger is permitted up to 32A (7kW) per phase.

So you'd be able to have a 22kW 'fast' charger.

Having two separate single-phase supplies to the house will cause significant phase imbalance at the local substation.

That leads to losses (as heat).

The DNO should be reducing phase-imbalance losses as part of their RIIO-ED2 Agreement with Ofgem.

Phase Imbalance losses nationwide are presently running at around 10% for sub-stations supplying domestic premises.

That's unsustainable!

Which DNO supplies the property?

Is it SSEN (Scottish & Southern), which supplies most of West Sussex?

Save energy... recycle electrons!

We would have gone for 3ph, but the upgrades required to the local power network were prohibitive. UKPN couldn't even give us an accurate quote for the work, but it was "at least £30,000 and could be considerably higher". We had to weigh up the pros and cons of the 3ph heat pump and EVCP and the simplicity of a 3ph supply, but we couldn't take the financial risk. Even £30,000 was crippling, but the prospect of "considerably higher" was just something we couldn't risk at the time.

OK, so that explains the 3ph issue a bit more.

You're on the sliver of West Sussex for which UK Power Networks is the DNO 😥

UKPN is Chinese-owned, and primarily being run as a financial operation.

If you'd been posting here when that discussion of £30k upgrade costs was happening, I'd have gone deeper into the architecture of the distribution grid in your area.

Consumers may only be asked for a 'contribution' towards network upgrade costs and reinforcement.

That suggest the true cost was significantly higher.

Those figures could've been made available to you for checking.

[NB This Forum is not just about heat-pumps. We will cover all aspects of energy and building design!]

Save energy... recycle electrons!

I wish I'd found this forum 2 years ago! When we started discussing the situation with UKPN, there was a really good person there who was thinking outside the box and was trying to come up with ways around the problems. Unfortunately he left and no one else seemed to care. It was a real struggle to get anything from UKPN. This was also the first utility that we were dealing with. I think if it had been at the end of the project, we would have had the experience to push back much harder like with had to with South East Water and BT and Openreach.

Posted by: @sbm74and just using the weather compensation curve on the heat pump. I’ll wait until the weather is colder. The Weather Control setting is currently off. There isn’t a lot of information about what this actually does, but it would seem that it checks the weather forecast and adapts its behaviour accordingly. I would be grateful if anyone has any knowledge of this feature and whether it’s worth enabling.

Oh good grief!

The Outside Air Temperature (OAT) is the main mechanism by which a heat-pump regulates the flow speed & temperature.

Setting Weather Control off is effectively ignoring all the clever/smart features embedded within the HP's software.

Your installer has set it up to operate from internal thermostats, like a boiler.

That is inefficient...

... and therefore doesn't comply with Building Regulations, Part-L

Moreover, Part-L, Section-9 stipulates that the homeowner must be provided with documents and instructions such that you can verify the efficiency of the installation,

and therefore be able to maintain it to use as little energy-input as possible.

This set of documents must be site-specific.

Handing you a folder with all the manufacturers' instructions for each component of the system does not comply.

Save energy... recycle electrons!

My understanding is that the OAT is being used. NIBE Weather Control seems to be an additional feature that looks at online weather forecasts and uses this information to help predict heating requirements.

Ah. That sounds better.

So that just leaves the heat-pumps in a battle whereby OAT-based weather compensation is being thwarted by thermostats turning zones off/on.

Posted by: @grahamfA floor at 60C would burn your feet and ruin your floor. I am not an expert, but I think even 40C UFH is considered dangerous.

I agree.

The absolute maximum I would expect to see for water entering an UFH manifold is 46°C.

The actual temperature you require depends on what the pipework is embedded in, and what material the floor surface is made of.

I am an expert on this!

... because I'm a self-builder with hands-on experience.

Do you know the composition of the floors which have UHF?

Do you have any photos of the UFH system being installed?

Save energy... recycle electrons!

Hi @sbm74 - wow, 650m2 - that's a big pile!

But, 60degC max flow temperature - eh, what, why? Building regulations also set the maximum design flow to be 55degC these days, and for UFH you'll only need something like 30-35degC if the system has been designed properly for an ASHP source (i.e.: 100mm spacing on the piping in the floor).

Has your installer used underfloor heating blending thermostats on the manifolds to on each zone? It could be your ASHP is set to kick out a far higher temperature than will ever be needed or is appropriate for UFH. The old school way of getting round a fixed non-modulating fired gas or oil boiler that could not supply heater water at less than 50-60degC was to blend [mix] high temperature flow from the boiler with water leaving the underfloor circuit to a lower temperature. From a thermal efficiency point of view, with electric heat pumps, that's thermodynamic lunacy! You're paying high and handsome in electricity consumption to generate water at far higher temperatures than is needed.

It sounds like you have a massive opportunity to de-clutter your system of things it should never have been fitted with, go open loop and set the ASHP to weather compensated control at a much more suitable system maximum flow temperature of around 35degC. 60degC might be the maximum flow the Nibe F2040 ASHPs can provide, (they use the rather obsolete R410a refrigerant gas), which is fine to generate your hot water and heat your cylinder, but should never be used for space heating.

Posted by: @sbm74All the thermostats are set for a max temperature of 46°.

Where are those thermostats?

On the UFH manifolds?

Photo?

The photo you've just posted of the pipe before screed is poured:

Is that a single loop for that room?

There appears to be only 1 pair of pipes coming through the doorway.

Save energy... recycle electrons!

Currently viewing this topic 3 guests.

Recently viewed by users: Richard24738 4 minutes ago, Mars 14 minutes ago, AllyFish 3 minutes ago, sbm74 1 hour ago, Transparent 1 minute ago.

- 26 Forums

- 2,171 Topics

- 47.8 K Posts

- 59 Online

- 5,744 Members

Podcast Picks

Latest Posts

-

RE: Testing new controls/monitoring for Midea Clone ASHP

A flow rate of 0.36 cubic metres per hour seems quite l...

By cathodeRay , 2 minutes ago

-

RE: Preparing for 2nd winter in new build house.

Where are those thermostats? On the UFH manifolds? ...

By Transparent , 4 minutes ago

-

Good day everyone. I'm new here and have a few question...

By Edin67 , 1 hour ago

-

RE: Boxt Heat Pump Installation Experience

Welcome to the forums. Was there any formal in-person...

By Mars , 3 hours ago

-

RE: Say hello and introduce yourself

@transparent Morning. Just put a lengthy post on the AS...

By sbm74 , 3 hours ago

-

RE: Big Changes Coming to Our Heat Pump System

@old_scientist 3. Some pipe work is ...

By GrahamF , 3 hours ago

-

RE: Help me keep the faith with my air source heat pump installation

@jamespa if I remember the insulation has a notch cut i...

By AdamK , 12 hours ago

-

RE: MCS certificate SCOP vs real-world performance

That may be contributing to lower than expected SCOP. ...

By JamesPa , 14 hours ago

-

-

RE: Mitsu PAR-WT60R Wireless Controller - options

How it does it's job is something of a mystery although...

By Abernyte , 21 hours ago

-

RE: Powerwall 3 or Myenergi or something else?

Yes I was thinking of outdoor, IP65 batteries with buil...

By Temperature_Gradient , 1 day ago

-

@jamespa Thanks. Yeah any adjustments Ive made at pr...

By cliffhanger , 1 day ago

-

RE: How to choose Towel Rails for an ASHP

@rob-nezard yes absolutely. Here is the link and a pho...

By GrahamF , 3 days ago

-

@mixergy Thanks for the update, I would appreciate some...

By bontwoody , 3 days ago

-

RE: Is Your Broadband Router the Weak Link in Your High-Tech Home?

Unfortunately I'm not that well connected 😂 ...

By Scalextrix , 3 days ago

-

RE: A Customer's Lessons Learnt from a Heat Pump Installation in a Large House

It is interesting to see what our new Grant Aerona 290 ...

By GrahamF , 3 days ago

-

RE: Midea ASHP – how to set weather compensation

I noticed that too and thought the same thing, but then...

By cathodeRay , 4 days ago

-

RE: Ya can’t win! It is S*d’s Law!

@old_scientist If IOF is still running next late spring...

By Toodles , 4 days ago

-

RE: Electricity price predictions

Those of you on Agile will do well tomorrow; there are ...

By Toodles , 4 days ago