For optimal performance, I strongly recommend that heat pump systems adhere to my advice and guidance below. It will make the system highly efficient, saving you a lot of money in the process.

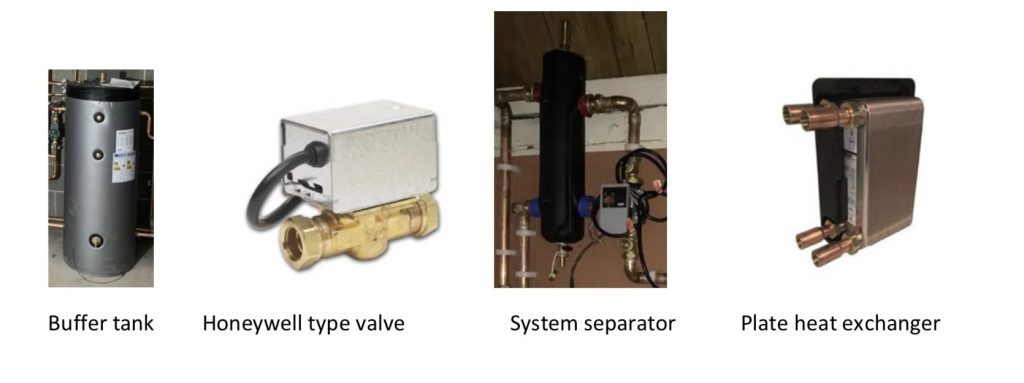

Start by piping the system in the same way as you would a gas boiler system, but use a high flow diverting valve (preferably full bore ball valve). Do not use Honeywell type valves because they are high temperature, low flow valves designed for gas boilers, not heat pumps.

Next, the heat pump must be controlled by the heat pump’s controller. Do not use third party thermostats as they can double the heating costs due to reduction in performance.

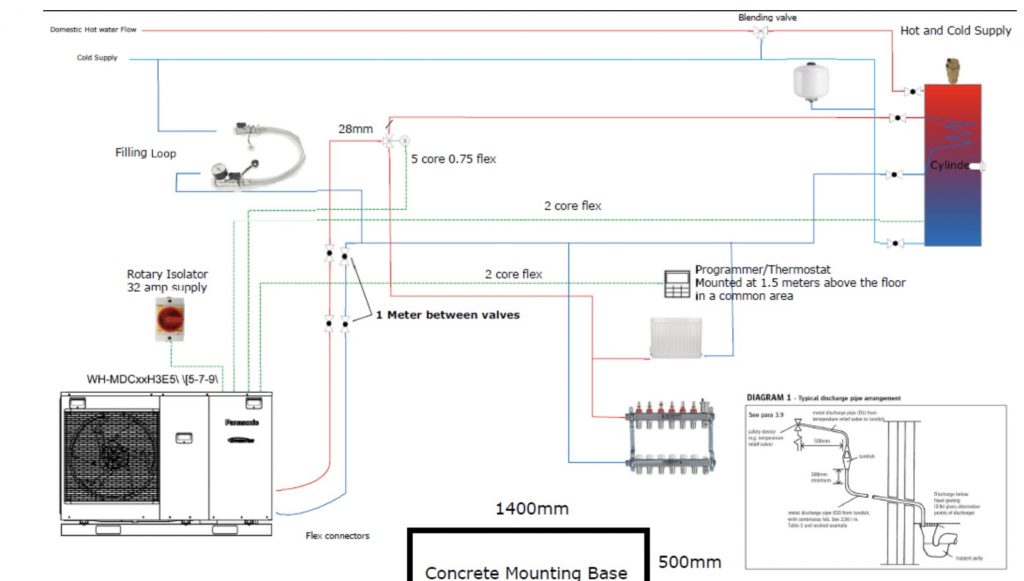

Install the manufacturer’s controller in a common area at a height of 1.5m above the floor level where it will not be affected by general space heating or cooling.

All common areas should be open zone: no TRVs should be installed on radiators in the hall, kitchen, lounge, dining room or bathrooms. Install controllers in bedrooms only in the form of modulating thermostats (not standard on-off) for underfloor heating or TRVs on radiators.

For open zone areas larger than 150m2, a secondary zone should be created. This is complex and should only be designed by a highly competent engineer taking the relevant flow temperatures into account.

Do not use antifreeze in the system. It reduces the ability of the water to carry heat and makes the water less viscous making it difficult to pump. It will significantly reduce the performance, increasing running costs in the process. Good manufacturers do not require it. If the installer states that it must have antifreeze according to the heat pump manufacturer, choose another manufacturer.

Do not use buffer tanks, system separation or plate heat exchanger separation under any circumstances. They will probably double your heating bill.

Follow this system design and you will have an efficient heat pump system. I have recently conducted a study, and I will be sharing my results here in due course, and have I found that a buffer system controlled by a third party thermostat is 89% more expensive to run than a direct system controlled by the heat pump controller. Watch this space for my findings.

Are distribution pumps not required in your proposed set up?

The panasonic unit has them inside as do many of the other monoblocks on the market, usually they are suficient for the installation, if on Microbore you may need another pump in series.

Should any secondary pump be piggybacked off the pwm feed to the primary circ pump?

My system has much of what you describe. With a seven-year warranty and build as Samsung recommends, wouldn’t deviating from design specs void the warranty?

Who’s Samsung manual? The manuals from different distributors differ in their wiring and plumbing. For example, the midsummer wholesale one offers an efficiency improvement over that supplied by freedom, through the use of a pwm primary pump and the advice to use the Samsung controller as the room stat.

Brendon I have exactly the valves you suggest avoiding. Honeywell. One on each of the CH & DHW as seen in the attached pic. What valve is it recommended they are changed to? Name of manufacturer and pics if possible. My system is still in warranty so it will be a case of convincing my installer to instal replacements.