I’m sorry, but as soon as a heat pump shows low flow, everyone panics and blames the kit. I’ve spent 15 years advising on this, and I’m done. This is it – I never want to discuss this again.

OK, so let’s begin. The person who designed your heat pump (or boiler) decided on a speed at which the water is supposed to move through it to ensure the heat pump (or boiler) works and does not damage itself. Running a heat pump or boiler with no water moving through it is not a great idea – you obviously get localised overheating.

So, a flow-measuring device is used to check the speed of the water.

It will look like the image above. These things are almost indestructible and rarely go wrong. So, first things first: if you have a low flow speed alarm, it means you have low water speed. It does not mean the flow meter is faulty. Get that idea out of your head.

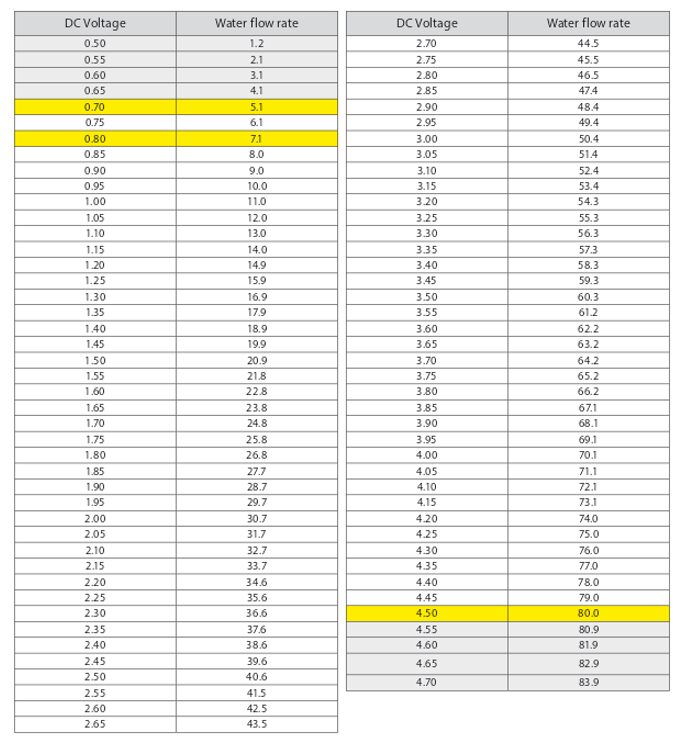

But if you are convinced the flow meter is faulty (it’s not), you can test it with a multimeter on DC voltage between the black and white wire. It must be plugged into the PCB and running. This is what you will find:

Note the yellow bit – this is where the flow meter will give you an alarm.

Most of these flow-sensing devices are quite clever. If the cable gets cut or unplugged, the unit sees a very high flow rate, something like 85 l/min. This should convince your heat pump something is wrong and give an alarm.

If you install the flow sensor backwards (which is nearly impossible because there is a big arrow on it), the flow rate will show 1.2 l/min when running, and you will get a low flow alarm.

Note that the genius who wrote the fault codes into the software at the factory tells you the flow is low. The idea that they might want to tell you what the flow rate should be completely escaped them. I think it would be nice if the controller told you what the flow rate was and what it should be. It could say, “The flow rate is 10 l/min; it should be 30 l/min,” but literally no heat pump does this.

As a rough guide, the flow rate should be 2 to 2.5 times the kW of the machine. For example, a 14kW heat pump = 28 to 35 litres per minute.

What to Do About the Alarm When It Happens

Let’s assume your unit wants to see 30 l/min of flow rate. If this is the case, the alarm will typically go off at about 10 l/min. Congratulations – you’ve managed to make the water move at less than one-third of the required flow rate. Well done. Just to put that into context, that’s like buying a car that can do 100 mph and only being able to get it to do 30 mph. You da man.

You need to get the water moving quicker.

On Initial Start-Up or After Draining the System

It’s likely about airlocks and closed valves. Here’s what I recommend:

1. Start at the outdoor unit and check every single valve is open. You’d be amazed how many times I’ve been to a site, opened the valve on the MagnaClean, and the unit runs.

2. If all the valves are open, it’s air in the system. Start at the outdoor unit. Have you got all the air out of it? I bet you haven’t. Loosen one of the flexi hoses (preferably the top one) and let some air out, allowing water to get to the pump so it’s not running dry. To be honest, you should have the flexis loose when you’re filling any heat pump to give the air somewhere to escape.

3. Check the flexi hoses. It’s really easy to kink these. They need to be sweeping; once they’re crushed, goodbye flow rate.

4. Check the cylinder. It’s simple to get the coil airlocked when filling because there’s a 2- or 3-port valve in the way. Manually open and close the 3-port or 2 x 2-ports when filling to stop this happening. Two 2-ports are much better than a 3-port because you can leave both open during filling.

5. Remember the golden rule: AAVs (auto air vents) don’t work on heat pumps. The water moves much too quickly, so there’s no time for the air to separate out of the water and come out of the AAV. They only work when the pumps stop.

6. Check the strainers every 10 minutes until you get excellent flow rates.

Don’t just leave the site once the flow alarm stops. Remember, it will run with 10 l/min, but you want much more than that. If the flow is constantly low, the unit will perform badly, you’ll blame the kit, the running costs will be high, and eventually, an engineer from the manufacturer will turn up and, quite rightly, throw you under the bus.

Intermittent Low Flow or Issues on Older Systems

If you’re getting low flow intermittently or on an older system that previously worked OK, it’s likely to be:

- Low water pressure: Someone may have moved a radiator to paint behind it.

- Dirt in the filters: Blocked filters restrict the flow. If they keep blocking, don’t blame the filter, and DON’T remove the gauze because it keeps blocking. It’s time to think; you didn’t do a thorough enough system flush.

- Mode-specific issues: If it only trips on low flow in heating or hot water, measure the flow rate in both modes. You’ll be amazed at the different figures you get.

- Low flow in hot water mode: Always caused by air in the cylinder coil. Drain down the system a bit, then refill it, but loosen the top nut of the cylinder coil to let the air out.

- Low flow in heating mode: Often caused by zone valves shutting occasionally or TRVs (thermostatic radiator valves) closing on warmer days, reducing the flow rate.

Closing Thoughts

If you want to work on heat pumps, you need an obsession with flow rates. Measure it every time you go to a site. Low flow is not going to be the pump or the flow sensor. Low flow means the water is moving too slowly. All you have to do is find out what YOU have done wrong.

Ironically, changing the pump or flow meter often solves low flow problems. Why? Because draining and refilling clears the airlock.

Now that’s it. Please, I implore you, never ask me about low flow again. I’m done. I retired from tech support four years ago because I couldn’t take any more questions about low flow.

Measure the flow rate where how explain what do I need.I am not paying £150:call out fee don’t have it.

Where a system has poor flow manufactures quick to blame the pipe sizing . In reality the pipe size is rarely to blame and is the least significant factor.

The problems are usually caused by pump unions with a small internal aperture, gauze filters with a high pressure drop, two port and 3 port valves with a small internal aperture. We would also expect there to be 18 -30kPa of pressure drop in the heat pump heat exchanger. UK market is price sensitive flooded with poor quality fittings and their suitability is seldom questioned.

Some manufactures have been known to recommend the use of flow setters. They have a very small bore and are designed to restrict flow and should never be used.

The sum of these pressure drops will be significantly greater than that attributed to the pipe size used.The designer must be aware of all pressure drops taking account of the viscosity of the glycol added and its effect on any device used to measure flow.